Pallet Integrity Inspection System | 3D Cameras & Dual Line Lasers | Customizable Defect Limits | by SICK

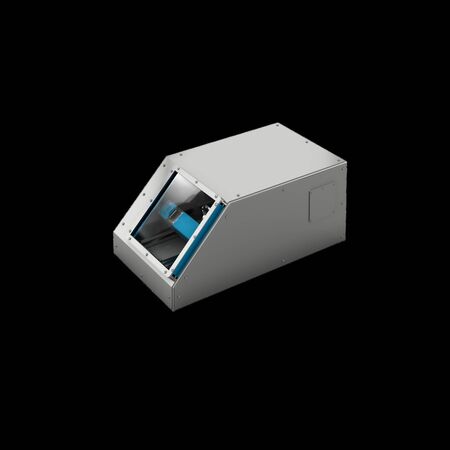

The Pallet Integrity Inspection System utilizes advanced 3D cameras and dual line lasers for non-contact quality control, ensuring accurate inspection of Euro pallets. Ideal for logistics and warehousing, it quickly detects defects like missing parts and cracks, while customizable settings allow for tailored inspections. With intuitive software and space-saving design, this system enhances safety and efficiency in pallet management.

Sign in

Please login to continue to your account.

Product Name/Title: Pallet Integrity Inspection System | 3D Cameras & Dual Line Lasers | Customizable Defect Limits | by SICK

Brand: SICK

SKU: 1144856

Alternatively Known As: Pallet Defect Detection System, Pallet Quality Inspection System, Euro Pallet Scanner, Pallet Damage Detection System

- 3D cameras and dual line lasers (class 2) for scanning during throughput

- Customizable defect limits for each defect type and pallet element

- System dimensions: 722 mm x 461 mm x 306 mm (PAIS system)

- Control cabinet dimensions: 665 mm x 356 mm x 786 mm

- Variant: Bottom-only inspection

- Intuitive software with warning messages and notifications

- Dimensions (H x L x W): 306mm x 722mm x 461mm

- Weight: 25 kg

- Non-contact quality control using 3D cameras and dual line lasers (class 2)

- Scans top, sides, bottom, and inside of pallets quickly and accurately

- Detects missing parts, cracks, and protruding nails on Euro pallets

- Customizable defect limits and pallet element inspections

- Intuitive software operation with warning messages and notifications

- Space-saving and optional dirt-proof system construction

- Supports creation of individual pallet types and inspection modifications

- Professional installation by qualified technicians is recommended to ensure proper system integration and calibration.

- Quality control in logistics and warehousing

- Inspection of Euro pallets for damage and defects

- Prevention of accidents and damage to goods during transport

- Customizable inspection for various pallet types and defects

- Complies with AS/NZS 4801 – Occupational Health & Safety Management Systems

- Reduces waste by early detection of damaged pallets preventing further damage to goods

- Non-contact inspection reduces need for manual handling and associated energy use

- Supports sustainable logistics by improving pallet reuse and safety

Standard manufacturer warranty applies; please refer to SICK for specific warranty terms.

The SICK Pallet Integrity Inspection System is available for immediate purchase, ideal for logistics, warehousing, and quality control applications.