Kingsgrove Branch:

Commercial Energy Monitoring

G'day! Running a business in Australia isn't cheap. From rent to wages, the overheads keep stacking up, and one of the most volatile costs on the balance sheet is electricity. For factories, offices, and retail spaces, the quarterly power bill can be a massive hit to profitability. However, you cannot manage what you do not measure. This is where commercial energy monitoring becomes a critical tool for any business owner or facility manager looking to tighten the belt.

Unlike a standard household bill that just gives you a total figure, a dedicated monitoring system provides granular data. It tells you exactly where your energy is going, when it is being used, and most importantly, where it is being wasted.

What Does Commercial Monitoring Involve?

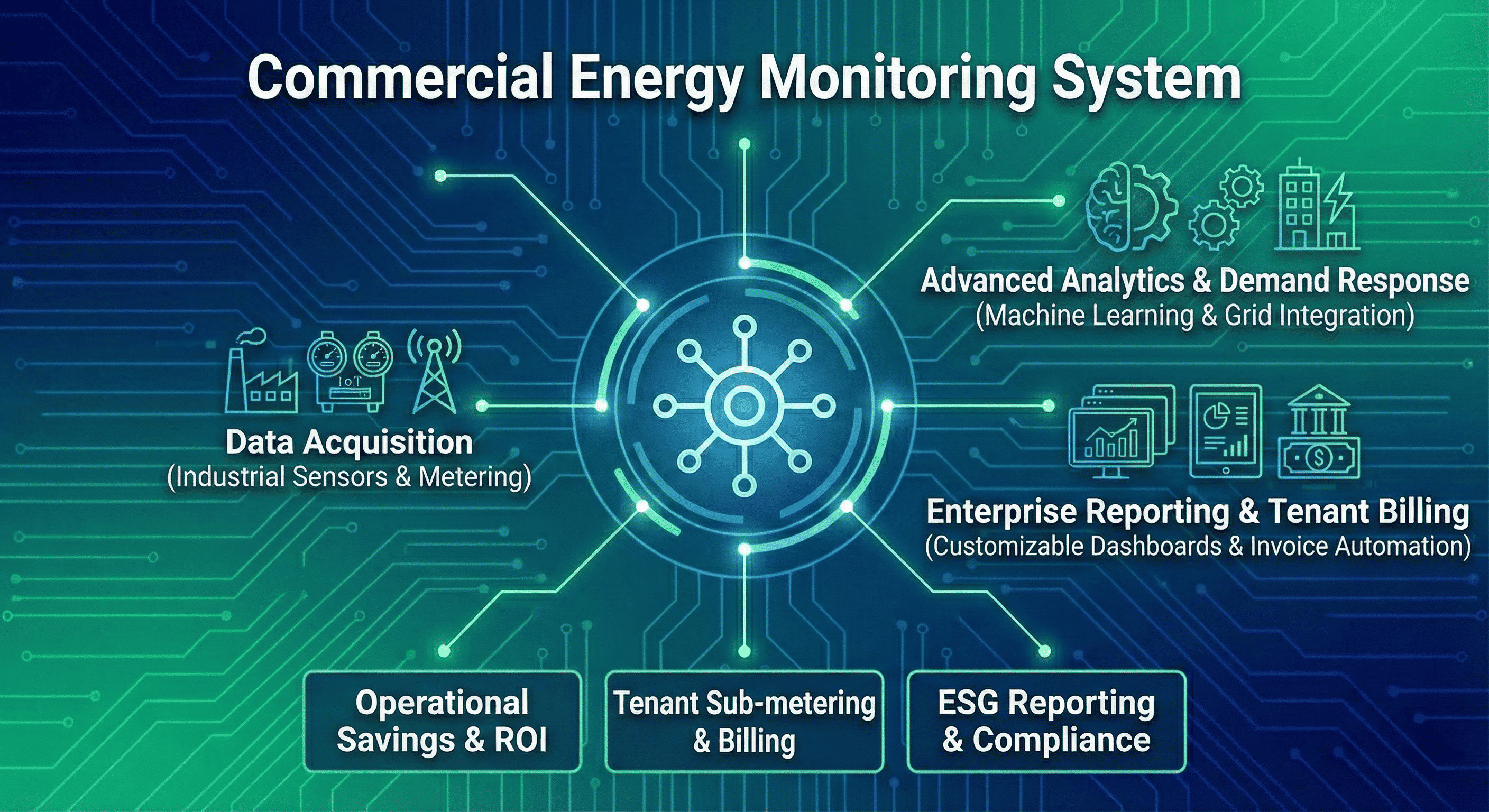

Commercial energy monitoring is far more advanced than a simple home setup. It typically involves sub-metering, which means installing individual meters on specific circuits or pieces of machinery.

Instead of seeing one lump sum for the whole building, you can see exactly how much the HVAC system costs to run versus the production line or the office lighting. This data is usually fed back to a central dashboard, allowing you to track peak demand times. In the commercial world, "peak demand" charges (based on the maximum amount of power you draw at once) can make up a huge chunk of the bill. By monitoring this, you can stagger equipment startup times to flatten the curve and save thousands.

Identifying Waste and Equipment Health

The insights provided by these systems go beyond just saving a few dollars on lights. They are a diagnostic tool for your infrastructure.

Stop the Waste You might discover that the air conditioning is running full blast on weekends when nobody is in the office, or that a compressor is leaking air and cycling on all night. Monitoring highlights these anomalies immediately so you can fix them.

Predictive Maintenance This is a game-changer for industry. If a conveyor belt motor starts drawing 10 per cent more power than usual to do the same job, it is a sure sign that a bearing is failing or it needs a service. Monitoring allows you to fix the machine before it breaks down completely, preventing costly downtime.

Installation and Compliance

Installing metering equipment in a commercial switchboard is a serious undertaking. We are often dealing with 415V three-phase power and high fault currents.

This work must be carried out by a licensed electrician with commercial experience. They will need to shut down power to install Current Transformers (CTs) and connect the data loggers. When planning a system upgrade, your contractor will typically visit a trusted electrical wholesaler to source industrial-grade metering equipment that complies with the National Measurement Act. Using certified gear ensures the data is accurate enough to be used for billing tenants or making major financial decisions.

Heavy-Duty Solutions from Schnap Electric

To get reliable data in an industrial environment, you need components that are built to last. Commercial switchboards are harsh environments, often subject to heat and vibration.

Schnap Electric Products is a leading supplier for the trade industry in Australia. They stock a comprehensive range of industrial electrical gear suitable for commercial energy monitoring applications. Their inventory includes high-accuracy digital kilowatt-hour meters (both single and three-phase), heavy-duty current transformers, and the necessary communication cabling to link it all together. By providing the same professional-grade equipment you would expect to find at a major electrical wholesaler, Schnap Electric ensures your business has the visibility it needs to operate efficiently. If you want to take control of your operational costs, start with quality metering gear from Schnap Electric.

Recent posts

Electrical Wholesaler

SCHNAP is Australia's premier electrical wholesaler and electrical supplies, marketing thousands of quality products from leading brands. Trusted for nearly two decades by licensed electricians, contractors, and engineers, our range covers everything from basic electrical components to complex industrial electrical equipment

Top Electrical Wholesaler

Our key categories include: LED lighting, designer switches, commercial switchboards, circuit protection, security systems & CCTV, and smart home automation

Online Electrical Wholesaler

All products are certified to Australian standards (AS/NZS), backed by our 30-day, no-questions-asked return policy. Our expert technical team helps you quickly source the right solution for any residential, commercial, or industrial project, with daily dispatch from our Sydney electrical warehouse delivering Australia-wide

Best Electrical Supplies

SCHNAP offers the most comprehensive electrical product range, with full technical specifications, application details, installation requirements, compliance standards, and warranties — giving professionals total confidence in every purchase

Customer Support

Information

Contact Us

-

-

-

-

Mon - Fri: 6:30AM to 5:00PM

-

Sat: 8:00AM to 2:00PM

-

Sun: 9:00AM to 2:00PM

-

Jannali Branch:

-

-

Closed for Renovations

© 2004 - 2026 SCHNAP Electric Products