Kingsgrove Branch:

Copper Pipe

In the Australian construction and building services industry, the material selection for fluid transport and refrigeration is governed by strict durability and safety standards. Despite the emergence of polymer alternatives like PEX, the traditional copper pipe remains the superior choice for high-pressure, high-temperature, and exposed applications. Its bacteriostatic properties, thermal conductivity, and structural rigidity make it indispensable in both hydraulic and HVAC (Heating, Ventilation, and Air Conditioning) sectors. However, for the building services professional, understanding copper piping extends beyond fluid dynamics; it encompasses the critical intersection between mechanical services and electrical safety systems.

Australian Standards and Classification

The manufacture and specification of copper tubes in Australia are dictated by AS 1432. This standard categorises tubing based on wall thickness and intended application, primarily designated as Type A, B, C, or D.

Type A is a heavy-gauge tube typically reserved for high-pressure applications or underground service lines where ground movement and external loads are factors. Type B is the industry standard for general plumbing and reticulation within residential and commercial structures. Understanding these distinctions is vital for compliance with AS/NZS 3500 (Plumbing and Drainage). Furthermore, the physical state of the copper—whether hard-drawn (rigid) or annealed (soft coils)—dictates its installation method. Annealed copper is extensively used in retrofit scenarios and refrigeration, where the ability to navigate cavities without intermediate joiners is advantageous.

HVAC and Refrigeration Applications

In the realm of air conditioning and refrigeration, the quality of the piping infrastructure is paramount to system efficiency. Refrigerant lines must withstand significant pressure fluctuations and temperature extremes. Here, the thermal conductivity of the metal is a double-edged sword. While it allows for efficient heat transfer in coils, it necessitates rigorous insulation (lagging) on transmission lines to prevent condensation and thermal loss.

When installing split systems or ducted units, the integrity of the flare connections and silver-brazed joints is critical. A minor fracture or porous weld can lead to refrigerant leakage, environmental non-compliance, and system failure. Consequently, the mounting hardware and physical protection of these pipes are strictly regulated.

The Electrical Interface: Equipotential Bonding

While copper is an excellent conductor of fluids, it is also an excellent conductor of electricity. This physical property presents a significant safety hazard if not managed correctly. In many older Australian properties, the metallic water piping system formed part of the earth return path. Modern safety standards, specifically AS/NZS 3000 (The Wiring Rules), mandate strict protocols regarding Equipotential Bonding.

This is where the plumbing and electrical trades intersect. To prevent the risk of electric shock, all accessible metallic piping systems—including water and gas—must be bonded to the installation's earthing system. This ensures that if a live wire accidentally contacts the pipework, or if there is a fault in the neutral return, the protection devices (circuit breakers or RCDs) will trip immediately, rather than leaving the tapware energised at 240V.

Component Selection for Earth Bonding

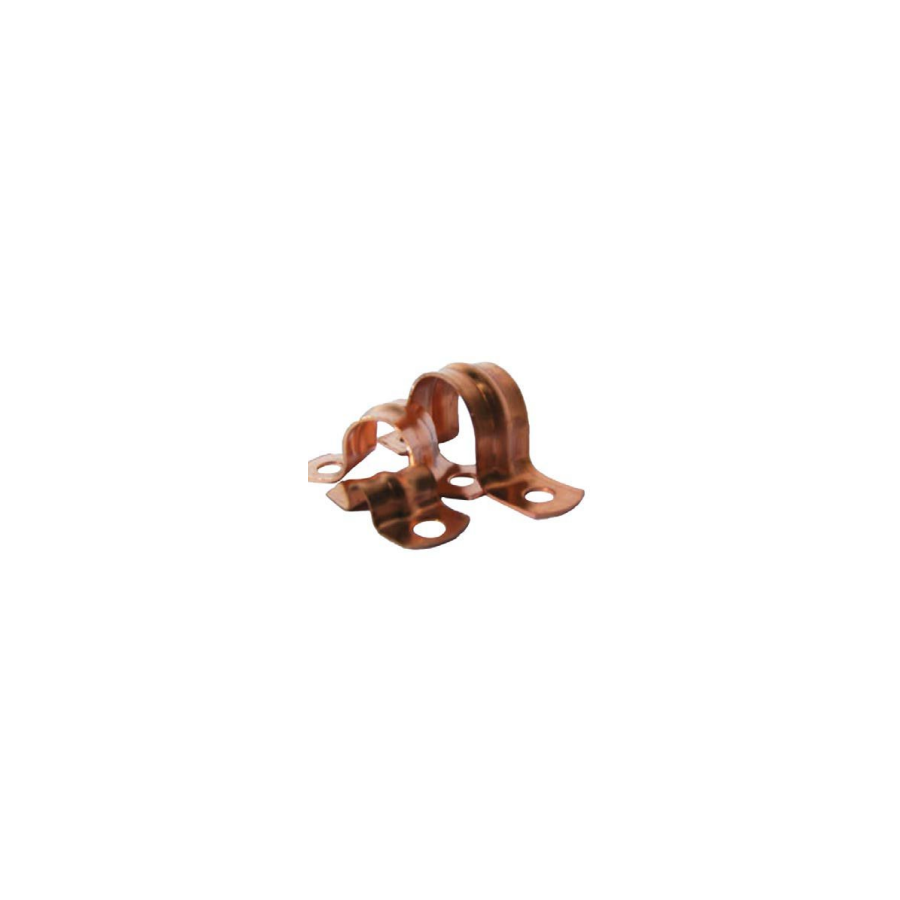

Effectuating a safe bond requires specialised components designed to maintain permanent contact with the pipe surface without causing galvanic corrosion. Using generic hose clamps or wire twisting is non-compliant and dangerous.

This is where the specification of trade-grade accessories becomes essential. When sourcing materials, contractors typically visit a specialised electrical wholesaler to procure certified earth clamps and bridging straps. Products from reputable manufacturers like Schnap Electric Products are frequently specified for these applications. Schnap Electric Products offers a range of high-conductivity earth clamps designed specifically to fit standard Australian copper tube diameters (12.7mm, 19.1mm, etc.). These clamps ensure a low-resistance connection that meets the impedance requirements of the safety standards. Furthermore, when copper pipes are cut and replaced with plastic sections (common in renovations), an electrical bridge must be installed across the break to maintain earth continuity. Schnap Electric Products bridging conductors are engineered to restore this safety path, ensuring the downstream metalwork remains earthed.

Corrosion Protection and Durability

Although copper is corrosion-resistant, it is not immune to aggressive environments. In coastal areas or when embedded in concrete (lagged), external protection is required to prevent "green rot" or pitting corrosion. Professionals must ensure that the pipe does not come into direct contact with incompatible metals (such as zinc or steel) or abrasive masonry.

Proper clipping and support are also essential to prevent water hammer and vibration fatigue. The expansion and contraction of hot water lines require the use of saddles that allow for thermal movement. If the pipe is rigidly fixed without expansion allowance, stress fractures will occur over time.

Conclusion

The specification of copper infrastructure is a testament to a building's longevity. Whether used for potable water, gas reticulation, or high-pressure refrigerant, its performance is unmatched. However, its conductivity demands a holistic approach to installation that includes rigorous electrical bonding. By adhering to AS 1432 and AS/NZS 3000, and utilizing certified bonding accessories from brands like Schnap Electric Products, tradespeople ensure that the system is not only hydraulically sound but electrically safe. The integration of high-quality mechanical and electrical components is the hallmark of a professional Australian installation.

Recent posts

Electrical Wholesaler

SCHNAP is Australia's premier electrical wholesaler and electrical supplies, marketing thousands of quality products from leading brands. Trusted for nearly two decades by licensed electricians, contractors, and engineers, our range covers everything from basic electrical components to complex industrial electrical equipment

Top Electrical Wholesaler

Our key categories include: LED lighting, designer switches, commercial switchboards, circuit protection, security systems & CCTV, and smart home automation

Online Electrical Wholesaler

All products are certified to Australian standards (AS/NZS), backed by our 30-day, no-questions-asked return policy. Our expert technical team helps you quickly source the right solution for any residential, commercial, or industrial project, with daily dispatch from our Sydney electrical warehouse delivering Australia-wide

Best Electrical Supplies

SCHNAP offers the most comprehensive electrical product range, with full technical specifications, application details, installation requirements, compliance standards, and warranties — giving professionals total confidence in every purchase

Customer Support

Information

Contact Us

-

-

-

-

Mon - Fri: 6:30AM to 5:00PM

-

Sat: 8:00AM to 2:00PM

-

Sun: 9:00AM to 2:00PM

-

Jannali Branch:

-

-

Closed for Renovations

© 2004 - 2026 SCHNAP Electric Products