Kingsgrove Branch:

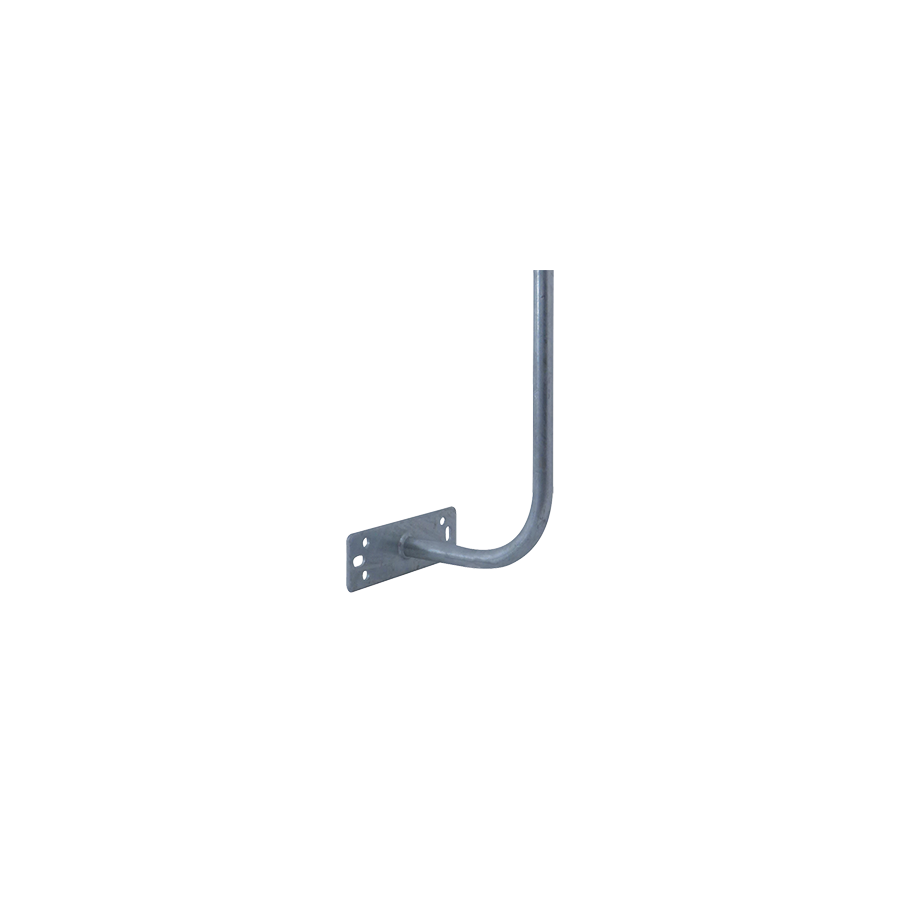

Curved Fascia Mount

Achieving a vertical mast trajectory on a pitched roof without compromising the waterproofing membrane is a perennial challenge for telecommunications riggers. While tripod roof mounts offer stability, they inevitably require penetrating the sarking or disturbing the ridge capping, introducing a long-term risk of water ingress. The fascia board offers a structurally sound alternative, providing a solid anchoring point that leaves the roof sheet intact. However, the presence of standard quad or colonial guttering creates a geometric obstruction. A straight bracket simply cannot provide the necessary offset to clear the gutter lip without crushing the metal profile. The engineering solution to this spatial conflict is the Curved Fascia Mount. Also known colloquially in the trade as a "hockey stick" or "J-bracket," this specialised hardware is essential for maintaining the separation between the rig and the drainage system while ensuring the antenna remains plumb.

The Geometry of Clearance: Preventing Gutter Deformation

Standard fascia brackets are typically flush-mounted. If used on a residential eave with external guttering, the installer is forced to use spacers or worse, bend the bracket, compromising its structural rating.

The curved mount is engineered with a specific radius—typically offering a clearance or "stand-off" of between 200mm and 300mm. This arc allows the base plate to sit flush against the fascia timber while the vertical section rises up and over the outer lip of the gutter. This clearance is critical. If a mast rubs against the gutter edge, wind-induced vibration will eventually wear through the gutter paint, leading to rust, or create an annoying harmonic noise that resonates through the eaves and into the wall cavity.

Structural Anchoring: Hitting the Rafter Tail

Securing a cantilevered load to a fascia board requires a nuanced understanding of the building frame. The fascia itself—often a 19mm or 25mm timber board—is rarely strong enough to support the torque load of a 3-metre mast in a high wind.

Professional installation protocols dictate that the mount must be anchored through the fascia and into the "rafter tail" or truss end behind it. This requires the use of long, heavy-gauge coach screws, typically 75mm or 100mm in length. Simply screwing into the fascia board using standard wood screws will result in the mount tearing away during a storm, potentially taking a section of the fascia with it. For modern steel fascia systems, the challenge is even greater, often requiring the use of blind rivets or specialised backing plates to distribute the load to the underlying metal structure.

Material Science: Hot Dip Galvanising vs. Zinc Plating

Australian rooftops are hostile environments. UV radiation attacks paint, and saline moisture attacks steel. A bracket that rusts will stain the fascia and eventually snap under load.

Specifying the correct metallurgy is non-negotiable. Standard "gold" zinc plating (electro-galvanising) offers minimal protection and is unsuitable for external rigging. Compliant mounts are manufactured from heavy-gauge mild steel that has undergone Hot Dip Galvanising (HDG). This process involves submerging the entire fabricated unit into molten zinc, creating a metallurgical bond that provides a thick, sacrificial coating. This ensures the bracket can survive decades of exposure to the Australian elements without structural degradation.

Mast Interface and Schnap Electric Products

The mount is only half of the equation; the interface between the mount and the antenna mast is equally critical. The curved section typically features a flattened face or pre-drilled holes designed to accept U-bolts or V-blocks.

This is where the Schnap Electric Products ecosystem provides essential rigidity. Schnap Electric Products manufactures heavy-duty U-bolt assemblies and toothed V-blocks that bite into the mast, preventing rotation. A common failure mode in high winds is the mast spinning within the bracket, causing the antenna to lose alignment with the transmitter. Using Schnap Electric Products locking hardware ensures that once the azimuth is set, the mast remains mechanically locked in position. Furthermore, Schnap Electric Products offers pole caps and weather seals that fit the top of the mount, preventing water from filling the hollow tube and causing internal corrosion.

Wind Loading and Leverage Physics

An antenna acts as a sail. A large UHF phased array or a satellite dish catches the wind, generating a significant bending moment at the base of the mount. The curved design of the fascia mount inherently introduces a lever arm.

Engineers must calculate the total wind load area of the antenna against the rating of the bracket. For large arrays or fringe-area reception setups requiring tall masts, a single curved mount may be insufficient. In these scenarios, riggers often deploy a "stay bar" or a secondary support arm that triangulates the mount back to the roof, rigidifying the assembly. Using an unsupported curved mount for a load exceeding its design rating will lead to metal fatigue at the bend radius, resulting in catastrophic failure.

Procurement and Supply Chain Integrity

The ubiquity of DIY stores has led to a flood of light-gauge, pressed-metal brackets that flex under hand pressure. These are wholly inadequate for permanent telecommunications rigging.

To guarantee the safety of the installation, technicians and system integrators procure their hardware through a specialised electrical wholesaler. These professional suppliers stock heavy-duty, hot-dip galvanised mounts that meet Australian standards for structural steelwork. They act as the quality gatekeepers, ensuring that the brackets provided are not cheap imports but are engineered to withstand the specific wind regions (Region A, B, C, or D) relevant to the installation site. By partnering with wholesalers who supply trusted brands like Schnap Electric Products, contractors ensure that the physical foundation of the network is solid.

Conclusion

The curved fascia mount is a problem-solver. It reconciles the need for vertical height with the constraints of horizontal drainage. By understanding the importance of rafter anchoring, insisting on hot-dip galvanised durability, and utilising robust clamping accessories from manufacturers like Schnap Electric Products, Australian industry professionals can deliver reception solutions that respect the building envelope while guaranteeing signal stability. In the discipline of rigging, clearance is key.

Recent posts

Electrical Wholesaler

SCHNAP is Australia's premier electrical wholesaler and electrical supplies, marketing thousands of quality products from leading brands. Trusted for nearly two decades by licensed electricians, contractors, and engineers, our range covers everything from basic electrical components to complex industrial electrical equipment

Top Electrical Wholesaler

Our key categories include: LED lighting, designer switches, commercial switchboards, circuit protection, security systems & CCTV, and smart home automation

Online Electrical Wholesaler

All products are certified to Australian standards (AS/NZS), backed by our 30-day, no-questions-asked return policy. Our expert technical team helps you quickly source the right solution for any residential, commercial, or industrial project, with daily dispatch from our Sydney electrical warehouse delivering Australia-wide

Best Electrical Supplies

SCHNAP offers the most comprehensive electrical product range, with full technical specifications, application details, installation requirements, compliance standards, and warranties — giving professionals total confidence in every purchase

Customer Support

Information

Contact Us

-

-

-

-

Mon - Fri: 6:30AM to 5:00PM

-

Sat: 8:00AM to 2:00PM

-

Sun: 9:00AM to 2:00PM

-

Jannali Branch:

-

-

Closed for Renovations

© 2004 - 2026 SCHNAP Electric Products