Kingsgrove Branch:

Electric Cable Duct Systems

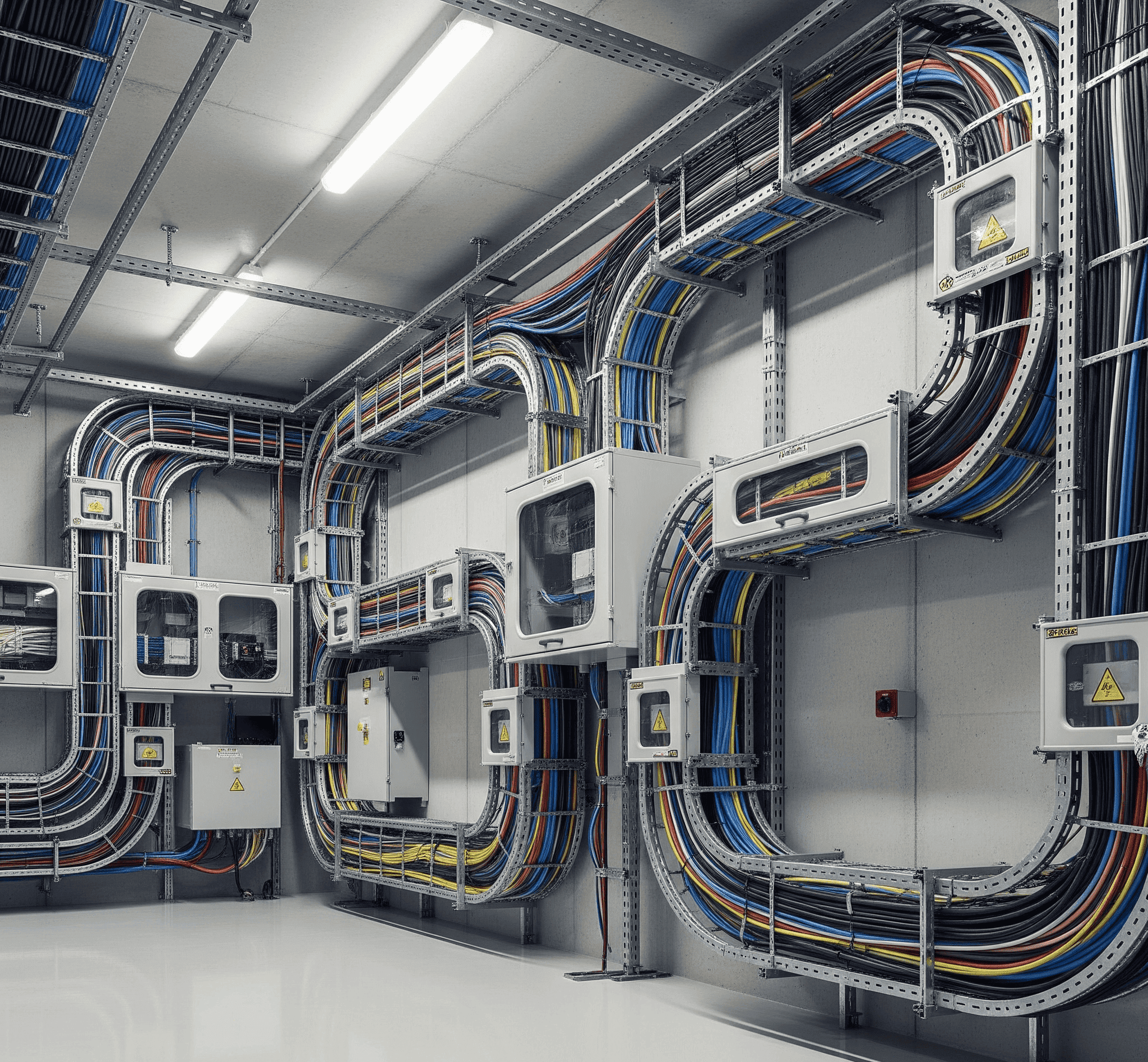

In today's electrically-powered world, managing the vast network of cables that power our homes, offices, and industries is more critical than ever. A well-organized and protected cabling infrastructure is not just a matter of neatness; it's a fundamental requirement for safety, efficiency, and compliance. This is where electric cable duct systems come into play, providing a robust framework for managing and safeguarding electrical wiring. For any professional electrician, contractor, or project manager in Australia, understanding the nuances of these systems is paramount to delivering a high-quality and compliant installation.

The Unseen Benefits of a Well-Managed Cabling Infrastructure

At its core, an electric cable duct system is a channel or enclosure used to protect and route electrical cables. The benefits of implementing a comprehensive cable management solution extend far beyond simply hiding wires from view.

A professionally installed ducting system is a critical safety measure. It protects cables from physical damage, moisture, and dust, which can all lead to insulation failure, short circuits, and potential fire hazards. For Australian workplaces, a properly managed cabling system is a key component of ensuring a safe environment for employees and the public, minimizing trip hazards and preventing accidental contact with live wires.

Furthermore, adherence to Australian standards is non-negotiable in the electrical industry. Electric cable duct systems help ensure compliance with regulations such as the AS/NZS 3000:2018 Wiring Rules, which outline the requirements for the selection and installation of wiring systems. A compliant installation is not only a legal requirement but also a hallmark of professional workmanship.

In the long run, a well-organized ducting system significantly improves efficiency. It simplifies maintenance and troubleshooting by providing easy access to cables. When upgrades or changes are needed, a structured cabling system saves valuable time and reduces labor costs. For businesses, this translates to less downtime and a more agile infrastructure that can adapt to future technological demands.

Types of Electric Cable Duct Systems: A Comparison for Australian Conditions

Choosing the right electric cable duct system depends on the specific application, environmental factors, and budget. In Australia, the most common materials are PVC and metal, each with its own set of advantages.

PVC (Polyvinyl Chloride) ducting is a popular choice for its versatility, lightweight nature, and cost-effectiveness. It is corrosion-resistant, making it suitable for a wide range of indoor and some outdoor applications. However, standard PVC may not be suitable for environments with extreme temperatures or high exposure to UV radiation, which can cause it to become brittle over time.

Metal ducting, typically made from steel or aluminum, offers superior mechanical protection and fire resistance. This makes it an ideal choice for industrial environments, high-traffic areas, and applications where a higher level of durability is required. While generally more expensive than PVC, its longevity and robustness can offer better long-term value in demanding conditions.

Beyond the materials, there are several common types of ducting systems used across Australia:

- Skirting Ducts: These are designed to be installed at the base of walls, providing a discreet and aesthetically pleasing way to run cables around a room. They are a popular choice for offices, schools, and modern residential buildings where a clean and unobtrusive finish is desired.

- Floor Cable Protection: In open-plan offices and retail spaces, cables often need to cross open floor areas. Floor cable protectors, also known as cable ramps or covers, are essential for preventing trip hazards and protecting cables from foot traffic and equipment.

- Dado Trunking: Installed at dado rail height (typically around 900-1500mm from the floor), this type of trunking is common in commercial and healthcare settings. It provides convenient access to power and data outlets at a practical height for workstations and equipment.

Key Applications Across Australian Industries

The versatility of electric cable duct systems means they are integral to a vast array of projects across the country.

In the residential sector, skirting ducts and other forms of mini-trunking are increasingly being used to manage the growing number of cables for home entertainment systems, home offices, and smart home technology. They provide a neat and tidy solution that complements modern interior designs.

For commercial buildings, such as offices, retail outlets, and data centers, effective cable management is crucial for operational efficiency and safety. A combination of skirting ducts, floor trunking, and overhead cable trays is often used to create a comprehensive and adaptable cabling infrastructure that can support a high density of power and data cables.

In the demanding industrial sector, including factories, warehouses, and processing plants, heavy-duty metal ducting is essential. It provides the necessary protection for cables against harsh environmental conditions, chemical exposure, and mechanical impact, ensuring the reliability of critical power and control systems. For specialized applications, such as in the Australian resources and mining sectors, robust and corrosion-resistant cable protection is paramount.

Installation and Compliance: Getting it Right

A successful installation of an electric cable duct system requires careful planning and adherence to Australian standards. Key considerations include:

- Cable Capacity: The ducting must be appropriately sized to accommodate the current number of cables with room for future expansion. Overfilling a duct can lead to overheating and make future maintenance difficult.

- Bending Radius: It is crucial to respect the minimum bending radius of the cables being installed to prevent damage to the conductors and insulation.

- Segregation of Services: In many applications, it is necessary to separate power cables from data and communication cables to prevent electromagnetic interference. Multi-compartment trunking is an effective solution for this.

- Earthing and Bonding: For metal ducting systems, proper earthing and bonding are essential to ensure electrical safety, in line with the AS/NZS 3000:2018.

By following these guidelines and adhering to the relevant Australian standards, you can ensure a safe, reliable, and professional installation that will stand the test of time.

In conclusion, electric cable duct systems are a fundamental component of modern electrical installations in Australia. They provide the necessary framework for a safe, compliant, and efficient cabling infrastructure across a wide range of applications. By choosing the right type of ducting and ensuring a professional installation, you can deliver a high-quality solution that meets the demands of today's technology-driven world. For a comprehensive range of quality cable management solutions tailored to the needs of the Australian market, trust Schnap to provide the products and expertise you need for your next project

Recent posts

Electrical Wholesaler

SCHNAP is Australia's premier electrical wholesaler and electrical supplies, marketing thousands of quality products from leading brands. Trusted for nearly two decades by licensed electricians, contractors, and engineers, our range covers everything from basic electrical components to complex industrial electrical equipment

Top Electrical Wholesaler

Our key categories include: LED lighting, designer switches, commercial switchboards, circuit protection, security systems & CCTV, and smart home automation

Online Electrical Wholesaler

All products are certified to Australian standards (AS/NZS), backed by our 30-day, no-questions-asked return policy. Our expert technical team helps you quickly source the right solution for any residential, commercial, or industrial project, with daily dispatch from our Sydney electrical warehouse delivering Australia-wide

Best Electrical Supplies

SCHNAP offers the most comprehensive electrical product range, with full technical specifications, application details, installation requirements, compliance standards, and warranties — giving professionals total confidence in every purchase

Customer Support

Information

Contact Us

-

-

-

-

Mon - Fri: 6:30AM to 5:00PM

-

Sat: 8:00AM to 2:00PM

-

Sun: 9:00AM to 2:00PM

-

Jannali Branch:

-

-

Closed for Renovations

© 2004 - 2026 SCHNAP Electric Products