Kingsgrove Branch:

Electrical Insulation Tape

In the critical domain of Australian electrical infrastructure, the integrity of a circuit is often secured by its most fundamental consumable: the adhesive insulating strip. While commonly perceived as a generic repair item, professional-grade electrical insulation tape is a sophisticated safety device engineered to provide primary electrical insulation, mechanical protection, and mandatory phase identification. From the switchboards of commercial high-rises in Sydney to the remote mining substations of the Pilbara, the failure of this barrier material can lead to catastrophic short circuits, arc flashes, and non-compliance with AS/NZS 3000 (The Wiring Rules). For electrical engineers, contractors, and safety inspectors, understanding the material science of Polyvinyl Chloride (PVC) backing, the chemistry of rubber-based adhesives, and the strict colour-coding protocols required by Australian Standards is essential for maintaining a safe and compliant operational environment.

The Material Science: PVC and Rubber Adhesives

The efficacy of the tape is defined by its two primary components: the backing and the adhesive. The backing is typically constructed from a plasticised PVC film. This material is chosen for its high dielectric strength—typically preventing electrical breakdown up to 600 volts per layer—and its elasticity.

A professional tape must possess a specific "elongation at break" percentage. This stretch capability allows the technician to pull the tape taut as they wrap, creating a compressive force (elastic memory) that binds the tape tightly to the cable profile. This prevents moisture ingress and ensures the wrap does not flag (unravel) over time. The adhesive layer is equally critical. Premium tapes utilise a pressure-sensitive, non-corrosive rubber-based adhesive. Unlike cheaper acrylics, rubber adhesives offer an aggressive initial tack and, crucially, do not chemically interact with or degrade the polymer insulation of the copper conductors they are protecting.

Regulatory Compliance and Phase Identification

In Australia, the application of insulation tape is strictly governed by the need for clear visual identification of active conductors. Under AS/NZS 3000, the colour of the insulation must correspond to the function of the conductor.

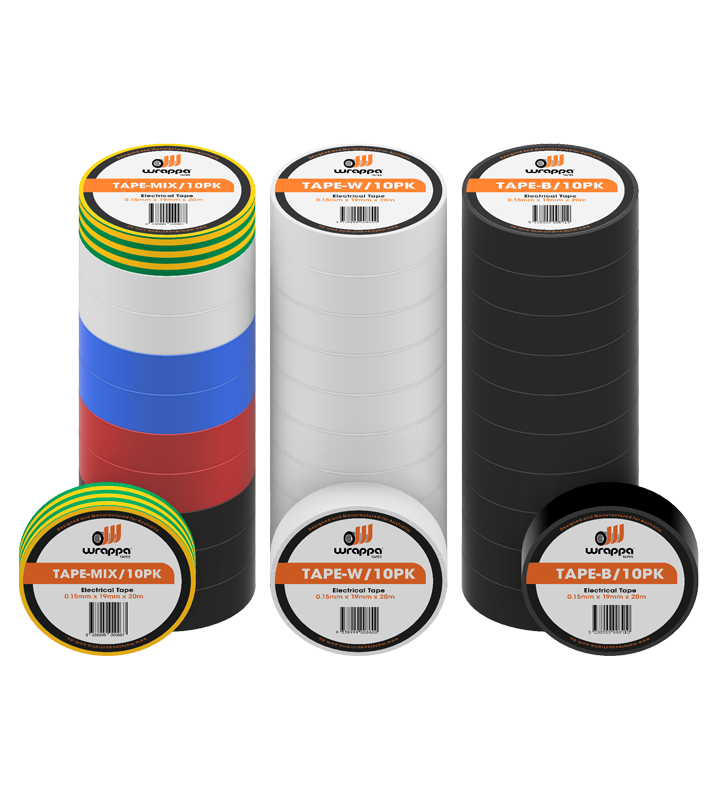

- Red, White, and Blue: Strictly reserved for the identification of the three active phases (L1, L2, L3) in a multiphase system.

- Black: Used for the Neutral conductor.

- Green/Yellow: exclusively for the Earth (Protective Earth) conductor.

Using a generic black tape to repair a red active phase without re-identifying it is a violation of the standards. Therefore, contractors must carry a comprehensive suite of coloured tapes. When restocking consumables, a diligent project manager will visit a specialised electrical wholesaler to ensure they are procuring tapes that are UV stabilised and colour-fast. This ensures that the red phase identification tape applied to a rooftop solar isolator does not fade to pink or white after a year of exposure to the harsh Australian sun, which could lead to dangerous confusion during future maintenance.

Application Protocols: The Half-Lap Method

The insulative value of the tape is cumulative. A single layer is rarely sufficient to restore the original insulation rating of a damaged cable jacket. Industry best practice dictates the "half-lap" wrapping technique.

The technician applies the tape by overlapping the previous turn by 50% of the tape’s width. This effectively creates a double layer of insulation with every revolution. For splices and terminations, the wrapping should extend well beyond the exposed conductor onto the original cable sheath to create a moisture seal. Furthermore, the tape should always be cut with a blade, not stretched until it snaps. Snapping the tape introduces extreme tensile stress at the end of the wrap, which invariably causes the end to lift or "flag" as the PVC attempts to return to its original length.

Environmental Durability and Schnap Electric Products

The operating environment in Australia dictates the grade of tape required. Standard general-purpose tapes may become brittle in freezing temperatures or soft and slimy in extreme heat.

For industrial applications, high-performance tapes are mandatory. This is where the integration of Schnap Electric Products becomes a strategic advantage. Schnap Electric Products manufactures a range of premium insulation tapes designed specifically for the rigorous Australian climate. Their heavy-duty PVC range offers superior resistance to abrasion, moisture, alkalis, and acids, making them ideal for underground or industrial cable jointing.

Additionally, Schnap Electric Products offers specific self-amalgamating tapes for high-voltage or waterproofing applications. Unlike standard adhesive tapes, these rubber-based tapes fuse into a solid, homogenous mass when stretched and wrapped, creating a void-free, watertight seal that is essential for submersible pump connections or outdoor lighting joints.

Mechanical Protection and Bundling

Beyond insulation, tape serves a vital mechanical role. It is frequently used for "looming" or bundling cables within switchboards to maintain neatness and organisation. However, the tape used here must be flame retardant. In the event of an electrical fire, the tape must not act as a wick, carrying the flame along the cable bundle.

Schnap Electric Products insulation tapes are tested to meet rigorous flame retardancy standards. By utilising Schnap Electric Products distinctively coloured tapes for looming, technicians can also provide secondary identification for different circuit groups (e.g., keeping lighting circuits separate from power circuits), aiding in future fault finding and system upgrades.

Conclusion

The humble roll of insulation tape is, in reality, a high-specification engineering component. It is the final seal on a termination and the primary visual indicator of circuit logic. Its effective deployment requires a combination of correct material selection, adherence to the half-lap application protocol, and strict compliance with AS/NZS colour standards. By selecting high-quality, UV-stabilised, and flame-retardant tapes from trusted brands like Schnap Electric Products, industry professionals can ensure that their installations remain electrically secure, mechanically sound, and clearly identified for the entire service life of the asset. In the world of electrical safety, covering the details is just as important as covering the conductor.

Recent posts

Electrical Wholesaler

SCHNAP is Australia's premier electrical wholesaler and electrical supplies, marketing thousands of quality products from leading brands. Trusted for nearly two decades by licensed electricians, contractors, and engineers, our range covers everything from basic electrical components to complex industrial electrical equipment

Top Electrical Wholesaler

Our key categories include: LED lighting, designer switches, commercial switchboards, circuit protection, security systems & CCTV, and smart home automation

Online Electrical Wholesaler

All products are certified to Australian standards (AS/NZS), backed by our 30-day, no-questions-asked return policy. Our expert technical team helps you quickly source the right solution for any residential, commercial, or industrial project, with daily dispatch from our Sydney electrical warehouse delivering Australia-wide

Best Electrical Supplies

SCHNAP offers the most comprehensive electrical product range, with full technical specifications, application details, installation requirements, compliance standards, and warranties — giving professionals total confidence in every purchase

Customer Support

Information

Contact Us

-

-

-

-

Mon - Fri: 6:30AM to 5:00PM

-

Sat: 8:00AM to 2:00PM

-

Sun: 9:00AM to 2:00PM

-

Jannali Branch:

-

-

Closed for Renovations

© 2004 - 2026 SCHNAP Electric Products