Kingsgrove Branch:

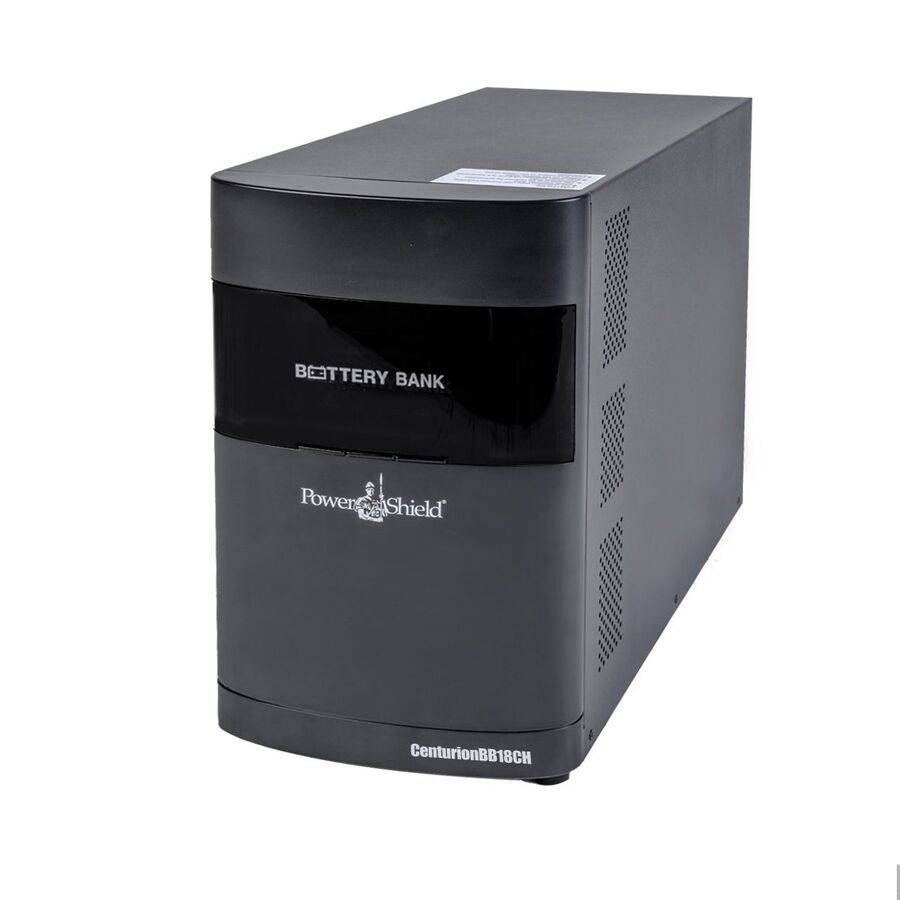

Extended Battery Module

In Australia’s unpredictable power environment, resilience is not optional. Severe storms, bushfire-related switching, grid instability, and regional supply constraints can all disrupt mains power without warning. For residential users, an outage may be inconvenient. For hospitals, data centres, telecommunications nodes, and logistics hubs, it is unacceptable.

A standard online double conversion UPS typically provides five to ten minutes of runtime at full load. That window is enough for controlled shutdown procedures. It is not enough to maintain operations during extended blackouts or to bridge the gap while a diesel generator starts and stabilises.

Where extended uptime is required, the solution is the Extended Battery Module, commonly referred to as an EBM. This external battery enclosure connects directly to the UPS DC bus. It increases available ampere-hour capacity and extends runtime from minutes to hours, depending on configuration.

DC Bus Integration and Capacity Expansion

An Extended Battery Module does not change the operating voltage of the UPS. Instead, it increases stored energy while maintaining the required DC bus voltage.

Every UPS inverter is designed to operate within a defined DC voltage window. For example, many three-phase systems operate around ±192V DC. The EBM must match this voltage exactly. Inside the module, individual battery blocks are wired in series to achieve the correct nominal voltage.

When the EBM is connected, it is placed in parallel with the UPS internal battery string. According to basic electrical principles, when identical voltage sources are paralleled, total current capacity increases. This effectively increases the available energy storage of the system.

If one battery string provides ten minutes of runtime, adding one EBM may double runtime. Adding two may increase it further. The relationship is not perfectly linear due to discharge characteristics. However, increased capacity significantly extends operational autonomy.

For facilities with defined disaster recovery requirements, runtime calculations are based on load profile, inverter efficiency, and battery discharge curves. Proper sizing ensures compliance with uptime targets.

Charging Logic and Recovery Time

One important consideration is recharge time. The UPS rectifier and charger are sized to recharge internal batteries within a specific period, often four to eight hours to reach 90 percent capacity.

When external battery modules are added, total capacity increases substantially. If charging capacity is not adjusted, recharge time may become excessive. After a prolonged outage, this can leave the facility exposed to a second event before batteries are fully restored.

Modern UPS systems communicate with EBMs through data connections. This allows the UPS firmware to recognise added capacity and adjust charging current accordingly. Some large-scale systems include supplementary charging boards within the EBM cabinet to assist the main charger.

Temperature management is equally critical. Charging generates heat. If battery temperature rises above safe thresholds, charging must be reduced or stopped. Thermal sensors within the EBM communicate with the UPS to protect battery life and prevent thermal runaway.

High Current Interconnection and Safety

The connection between the UPS and the Extended Battery Module carries high DC voltage and significant fault current. Safety and correct termination are essential.

These systems use heavy-gauge, double-insulated cables with high current connectors rated for the application. Standard low current connectors are not suitable. Voltage drop must be minimised. Excess resistance leads to heat generation and reduced efficiency.

Each EBM includes its own DC isolation device. This may be a fuse or DC-rated circuit breaker. It allows safe disconnection of the module for maintenance or replacement. Without proper isolation, parallel battery strings present dangerous fault energy.

Installation must follow relevant Australian electrical standards. Proper labelling, cable support, and mechanical protection are required to ensure long-term reliability.

Mechanical Considerations in Rack Environments

Extended Battery Modules are heavy. A fully populated rack-mounted module can weigh over 100 kilograms. This introduces structural considerations for server racks and equipment cabinets.

Racks must be stabilised to prevent tipping when battery trays are extended for servicing. Heavy-duty shelf rails and stabiliser kits support safe maintenance. Airflow management must also be preserved. Blocking ventilation paths can increase internal temperature and reduce battery lifespan.

Installers often rely on products from Schnap Electric Products to support secure mounting and cable routing. Flexible conduit, protective sleeving, and DC-rated circuit breakers enhance both safety and compliance.

Maintaining proper IP ratings and finger-safe barriers is critical in professional installations.

VRLA Versus Lithium Battery Modules

Most Extended Battery Modules use Valve Regulated Lead Acid batteries due to lower initial cost. VRLA batteries are reliable when maintained within temperature limits. However, they are sensitive to heat and have a limited design life, often three to five years in demanding environments.

Lithium-Ion battery modules are increasingly adopted in Australian facilities. They offer higher energy density, reduced weight, longer service life, and better performance at elevated temperatures. Over a ten-year lifecycle, lithium systems may reduce replacement costs and maintenance requirements.

Lithium systems incorporate integrated Battery Management Systems. These monitor cell voltage, temperature, and balance. While initial capital expenditure is higher, operational efficiency and reduced footprint can justify the investment.

The choice between chemistries depends on budget, space constraints, ambient temperature, and runtime requirements.

Runtime Planning and Facility Strategy

Extended Battery Modules are not installed arbitrarily. Runtime targets are determined by facility risk assessment. A hospital ICU may require several hours of support before generator stabilisation. A telecommunications site may need sufficient capacity to maintain connectivity during remote grid instability.

Load shedding strategies can also extend runtime. Non-essential circuits may be disconnected during outage conditions. This reduces discharge rate and preserves critical loads.

Professional design includes future scalability. Many UPS systems allow additional EBMs to be added as facility demand grows. Planning for expansion avoids costly system replacement later.

Procurement and Quality Assurance

Battery quality directly impacts system reliability. Inferior or aged cells can compromise an entire battery string. A single failing block may reduce total string voltage and stress the inverter.

Sourcing through reputable electrical wholesaler ensures fresh, date-coded stock and compatibility with the host UPS system. Matching firmware and electrical specifications prevents operational conflicts.

Compliant installation hardware, proper termination accessories, and documented commissioning protect long-term performance. Regular testing and maintenance further extend system life.

Conclusion

An Extended Battery Module transforms a UPS from short-term backup into a long-duration power solution. It extends autonomy, supports generator bridging, and protects mission-critical infrastructure from prolonged outages.

By understanding DC bus integration, managing charging logic, selecting appropriate battery chemistry, and ensuring safe high current installation, Australian facilities can achieve reliable and scalable runtime protection.

In critical environments, power continuity equals operational security. The Extended Battery Module delivers the time required to maintain control when the grid cannot.

Electrical Wholesaler

SCHNAP is Australia's premier electrical wholesaler and electrical supplies, marketing thousands of quality products from leading brands. Trusted for nearly two decades by licensed electricians, contractors, and engineers, our range covers everything from basic electrical components to complex industrial electrical equipment

Top Electrical Wholesaler

Our key categories include: LED lighting, designer switches, commercial switchboards, circuit protection, security systems & CCTV, and smart home automation

Online Electrical Wholesaler

All products are certified to Australian standards (AS/NZS), backed by our 30-day, no-questions-asked return policy. Our expert technical team helps you quickly source the right solution for any residential, commercial, or industrial project, with daily dispatch from our Sydney electrical warehouse delivering Australia-wide

Best Electrical Supplies

SCHNAP offers the most comprehensive electrical product range, with full technical specifications, application details, installation requirements, compliance standards, and warranties — giving professionals total confidence in every purchase

Customer Support

Information

Contact Us

-

-

-

-

Mon - Fri: 6:30AM to 5:00PM

-

Sat: 8:00AM to 2:00PM

-

Sun: 9:00AM to 2:00PM

-

Jannali Branch:

-

-

Closed for Renovations

© 2004 - 2026 SCHNAP Electric Products