Kingsgrove Branch:

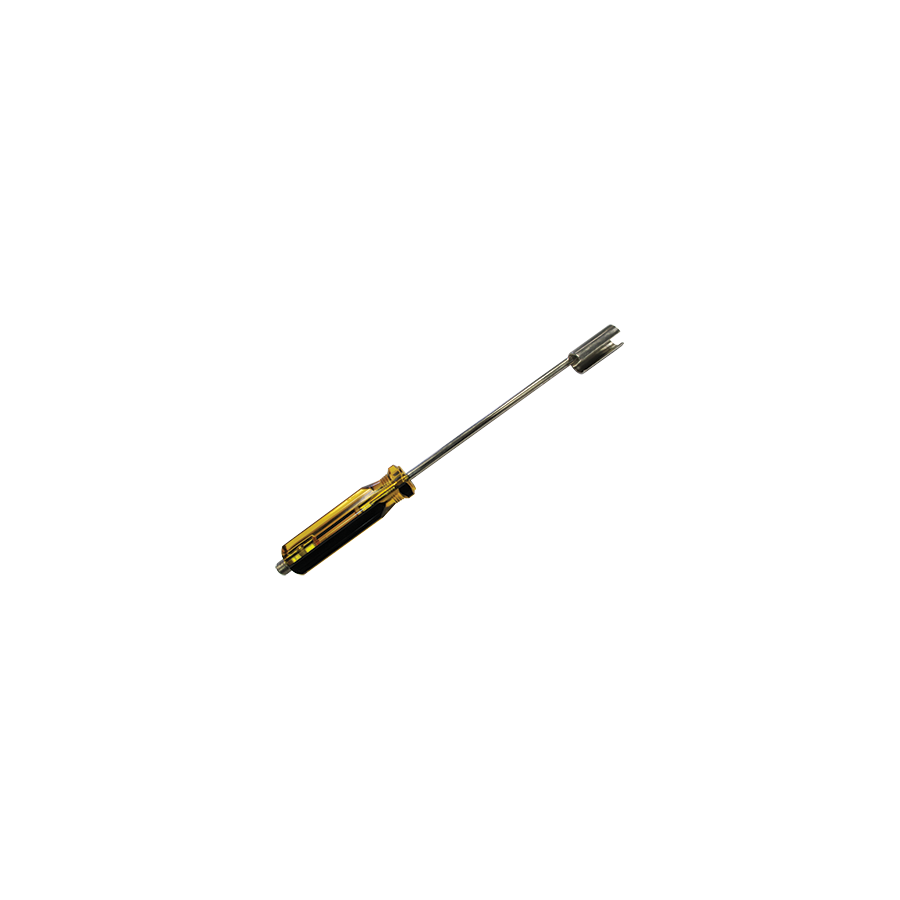

F Connector Removal Tool

Signal integrity within Hybrid Fibre Coaxial (HFC) and satellite distribution networks is frequently compromised not by the cable itself, but by the quality of the termination. The F-type connector, ubiquitous in Australian Pay TV, NBN, and MATV installations, relies on a precise mechanical interface to maintain the ground plane and prevent Radio Frequency (RF) ingress. However, the physical constraints of modern distribution hardware—where splitters and multitaps are densely packed to save space—render standard spanners and fingers useless. The technician’s ability to torque a connector correctly, or remove a seized unit without damaging the port, depends entirely on the deployment of a specialised F Connector Removal Tool. For telecommunications riggers and data cablers, this extended-shaft driver is not a luxury; it is a critical instrument for ensuring compliance with signal leakage standards.

The Geometry of High-Density Headends

Distribution amplifiers and passive splitters are designed with minimal spacing between ports to reduce the footprint of the enclosure. In a commercial MATV rack or a street-side node, the F-connectors are often mounted with less than 10mm of clearance between them.

Human fingers simply cannot generate the necessary torque in these confined spaces to tighten a connector to the required specification, nor can they grip a connector that has been over-tightened by a previous technician. Attempting to use a standard open-ended wrench often results in the tool bridging two ports, causing a short circuit on powered lines or stripping the threads of the adjacent connector. The removal tool addresses this through its cylindrical architecture. Featuring a hollow, elongated shaft with a hex-socket head, it slides over the coaxial cable and engages the nut from the top, rather than the side. This axial approach allows the technician to access deeply recessed ports without disturbing the surrounding infrastructure.

Torque Specifications and RF Shielding

A loose F-connector is a radio antenna. If the nut is not tightened to the correct torque specification—typically between 20 and 30 inch-pounds for commercial interfaces—the ground connection between the cable braid and the device chassis becomes intermittent. This gap allows external LTE (4G/5G) signals to leak into the network, causing pixelation and modem dropouts, while simultaneously allowing the internal signal to leak out, violating ACMA electromagnetic compatibility regulations.

Precision tools are engineered to facilitate this specific torque application. The handle of a professional removal tool is typically knurled and sized to allow the operator to apply substantial rotational force without slipping. Unlike a simple nut driver, the tool is designed to provide tactile feedback, ensuring the technician knows when the connector is seated firmly against the port face, compressing the moisture seal and locking the RF shield.

Ergonomics and Repetitive Strain Mitigation

Technicians working on NBN rollouts or large-scale apartment block upgrades may terminate hundreds of cables in a single shift. Manually twisting connectors onto threaded F-ports creates significant strain on the wrist and thumb joints, leading to Repetitive Strain Injury (RSI).

The mechanical advantage provided by the removal tool’s handle diameter significantly reduces the grip force required to spin the connector. High-quality variants feature a freely rotating shaft or a "spinner" sleeve, allowing the user to spin the connector on rapidly using the tool's momentum, only applying the final torque with a twist of the wrist. This ergonomic efficiency translates directly to speed and safety on the job site.

Integration with Schnap Electric Products

The durability of the tool must match the hardness of the connectors. Cheap plastic tools will round off when faced with a corroded or seized brass connector.

Schnap Electric Products supports the coaxial trade with high-grade steel tools designed for longevity. The metal alloy used in the socket head of a Schnap Electric Products tool is hardened to prevent deformation when applying high torque to stubborn connectors. Furthermore, the Schnap Electric Products design often incorporates a specific slot width in the socket to accommodate the thicker jacket of quad-shield RG6 and RG11 cables, ensuring that the tool is universally compatible with the heavy-duty cabling found in modern Australian installations.

Corrosion and Seizure Management

External taps and splitters are subject to thermal cycling and moisture. Over time, galvanic corrosion can cause the F-connector nut to seize onto the threaded port. Attempting to force a seized connector with pliers usually results in the port breaking off the circuit board, destroying the amplifier.

The removal tool allows for the application of pure rotational force without the lateral shearing force introduced by pliers. This axial torque is far more effective at breaking the corrosion bond. In severe cases, the extended reach of the tool keeps the technician's hands away from the work area, allowing for the safe application of penetrating oil if required.

Sourcing and Supply Chain Reliability

Professional tooling is rarely found in the aisles of a general hardware store. The specific dimensions of the hex head (7/16 inch) and the slot requirements for coaxial cable clearance dictate that these items are specialty products.

Infrastructure contractors procure these assets through a dedicated electrical wholesaler. These suppliers understand the difference between a residential "push-on" tool and a commercial "torque-capable" driver. By sourcing through these professional channels, technicians ensure they are equipped with tools that meet the rigorous demands of the field. A wholesaler who stocks brands like Schnap Electric Products provides the assurance that the tool will not fail mid-termination, preserving the integrity of the network and the efficiency of the workforce.

Conclusion

The F connector removal tool is the key to accessing the congested heart of the modern coaxial network. It bridges the gap between the physical constraints of the hardware and the electrical requirements of the signal. By enabling precise torque application, protecting valuable port threads, and utilizing durable metallurgy from manufacturers like Schnap Electric Products, Australian telecommunications professionals can ensure that every connection is tight, shielded, and compliant. In the world of RF transmission, a tight fit is the only acceptable standard.

Recent posts

Electrical Wholesaler

SCHNAP is Australia's premier electrical wholesaler and electrical supplies, marketing thousands of quality products from leading brands. Trusted for nearly two decades by licensed electricians, contractors, and engineers, our range covers everything from basic electrical components to complex industrial electrical equipment

Top Electrical Wholesaler

Our key categories include: LED lighting, designer switches, commercial switchboards, circuit protection, security systems & CCTV, and smart home automation

Online Electrical Wholesaler

All products are certified to Australian standards (AS/NZS), backed by our 30-day, no-questions-asked return policy. Our expert technical team helps you quickly source the right solution for any residential, commercial, or industrial project, with daily dispatch from our Sydney electrical warehouse delivering Australia-wide

Best Electrical Supplies

SCHNAP offers the most comprehensive electrical product range, with full technical specifications, application details, installation requirements, compliance standards, and warranties — giving professionals total confidence in every purchase

Customer Support

Information

Contact Us

-

-

-

-

Mon - Fri: 6:30AM to 5:00PM

-

Sat: 8:00AM to 2:00PM

-

Sun: 9:00AM to 2:00PM

-

Jannali Branch:

-

-

Closed for Renovations

© 2004 - 2026 SCHNAP Electric Products