Kingsgrove Branch:

Floor Duct

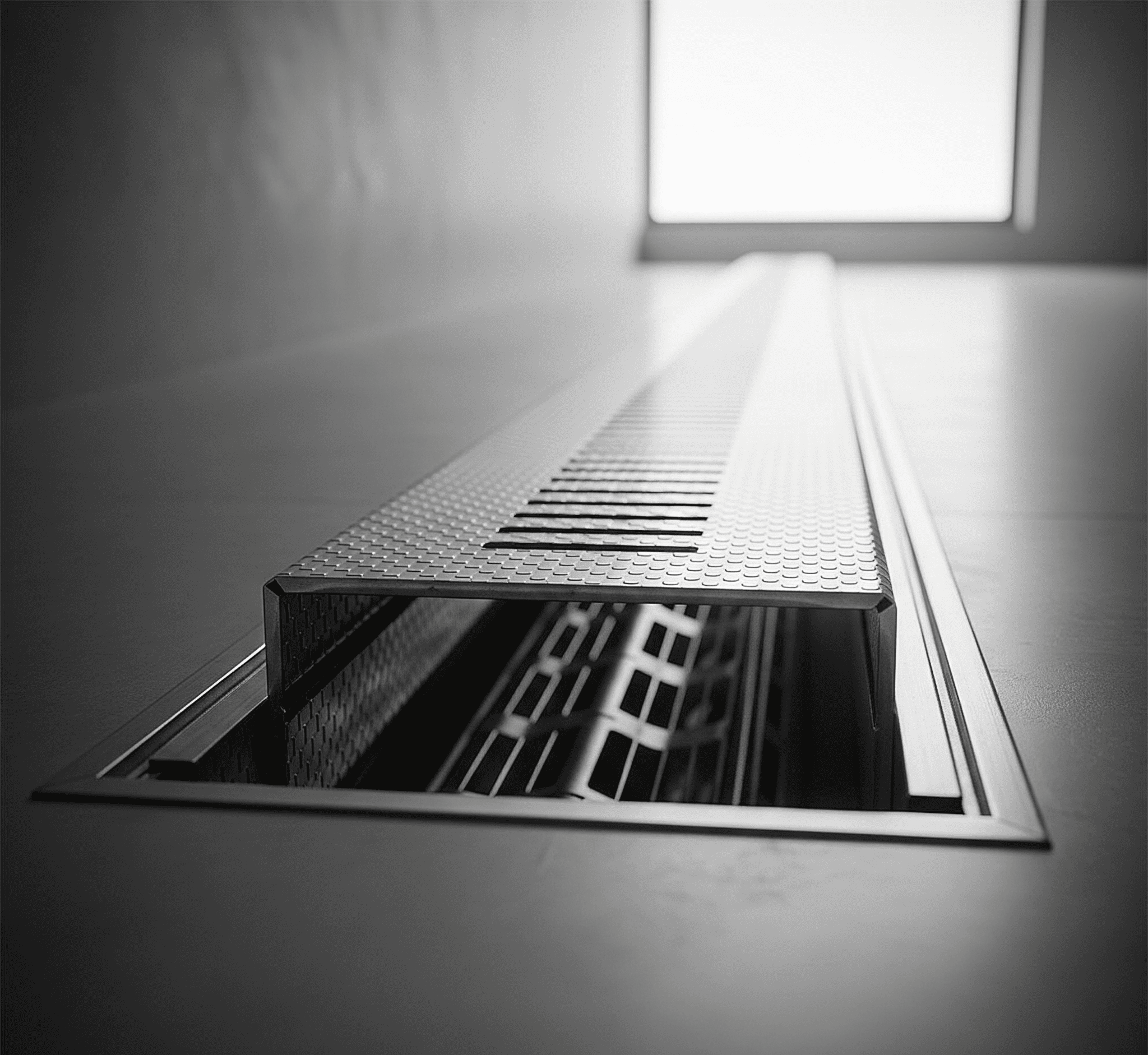

Floor duct systems are the unsung heroes of modern building ventilation. They quietly move air, often unseen, but critically important for a comfortable and healthy environment. Imagine a building breathing, its air circulating efficiently and silently through cleverly designed floor ducts. This guide delves into the world of floor ducts, exploring their design, installation, maintenance, and the crucial role they play in building ventilation

From basic definitions and historical context to the latest innovations, this comprehensive guide covers everything you need to know about floor duct systems. We'll explore the different types, their advantages and disadvantages, and the key factors to consider in design and installation. We'll also address common issues and solutions, offering practical advice for both professionals and enthusiasts

Introduction to Floor Ducts

Floor ducts are a crucial part of HVAC systems, bringing conditioned air directly to the space where it's needed. They're especially useful in buildings where efficient and targeted airflow is important. From offices to homes, floor ducts are a common and effective way to distribute air

Definition and Purpose

Floor ducts are air distribution components installed within the floor slab of a building. They carry conditioned air from the HVAC system to individual spaces or zones, providing efficient heating or cooling. This direct delivery of air minimizes the need for other distribution methods, making them particularly well-suited for large spaces with multiple zones. The placement within the floor is designed to reduce drafts and maximize the comfort of occupants

Types of Floor Ducts

Floor ducts come in various designs and materials. Common types include:

- Slab-mounted ducts: These are built directly into the concrete slab, often with pre-fabricated sections, offering a robust and concealed solution

- Suspended ducts: These are hung below the ceiling, but connected to the floor for delivery. They are adaptable to various spaces but may require more installation work

- Custom-designed ducts: For unique building layouts or specialized requirements, ducts can be custom-designed and fabricated to meet specific needs

The choice of material depends on factors like budget, aesthetics, and the building's overall design. Common materials include galvanized steel, aluminum, and fiberglass-reinforced polymers

Advantages and Disadvantages

- Advantages: Floor ducts are generally quiet, efficient, and create a clean aesthetic. They are often a more discreet way to distribute air, particularly in open-plan or large-scale spaces

- Disadvantages: Installation can be more complex than other HVAC methods. Careful design and planning are needed to avoid air leaks and optimize airflow, which can be more difficult to monitor in some instances

History of Floor Duct Development

Early floor duct systems were often simpler and less sophisticated than modern systems. As technology advanced, and as the need for energy efficiency increased, the design and construction methods improved significantly. Modern floor duct systems utilize advanced materials and insulation to maximize efficiency and minimize energy loss. See temp power pole

Typical Dimensions and Capacities

| Dimensions (LxWxH) | Applications |

|---|---|

| 10ft x 5ft x 2ft | Office spaces, large retail stores |

| 12ft x 6ft x 3ft | Residential buildings, industrial spaces |

| Variable | Specialized requirements, unique buildings |

Design and Construction Considerations

Effective floor duct design is crucial for optimal performance and building comfort. Key factors include efficient airflow, minimal noise, and compliance with safety regulations

Airflow Requirements, Noise Control, and Safety

Careful consideration of airflow patterns is essential. Duct sizing and placement must match the heating and cooling needs of the space. Proper soundproofing is necessary to minimize noise transmission to occupants. Adherence to building codes and safety regulations is paramount

Construction Methods and Materials

- Fabrication: Floor ducts can be fabricated from various materials. Selection is based on factors like cost, durability, and insulation properties. Cutting, bending, and welding are crucial steps in fabrication

- Insulation: Proper insulation is crucial for maintaining energy efficiency and reducing heat transfer

Configurations and Suitability

Different configurations of floor ducts suit different building layouts. Understanding how air will move within the system is essential for optimizing performance. Consideration of room size and placement is important for design

Sealing and Insulation

Careful sealing is essential to prevent air leaks. Efficient sealing prevents air from escaping the duct system, optimizing energy efficiency. Insulation reduces energy loss, improving the system's overall performance

Installation and Maintenance Procedures

Correct installation and ongoing maintenance are vital for long-term system reliability

Installation Steps

- Preparation: Proper planning, site preparation, and necessary measurements are crucial

- Connection to HVAC components: Connections to air handling units and other systems need to be precise and secure

- Commissioning: Verification and final adjustments are critical for achieving desired performance

Maintenance Routines

| Frequency | Safety Precautions |

|---|---|

| Quarterly | Turn off power, wear appropriate safety gear |

| Annually | Turn off power, wear appropriate safety gear |

Airflow and Ventilation

Understanding airflow within the duct system is key to efficient ventilation.

Airflow Principles and Factors

Airflow within the duct system is affected by duct size, shape, and placement. Proper design maximizes air delivery and minimizes pressure drops.

Airflow Issues and Solutions, Floor duct

Common issues include air leaks, restricted airflow, and uneven temperature distribution. Addressing these issues through maintenance and system adjustments can ensure efficient operation.

Applications and Case Studies

Floor ducts are widely used in diverse building types.

Diverse Building Applications

Floor ducts are suitable for a wide range of building types, from residential homes to large commercial buildings. Adaptability is key.

Related Systems and Components

Floor ducts integrate with other HVAC components.

Integration with HVAC Systems

Floor ducts work in conjunction with other HVAC components to provide a complete system. Understanding how these components interact is critical. See recessed floor box

Future Trends and Innovations

Floor ducts are evolving with advancements in technology.

Emerging Trends and Technologies

Smart technologies are becoming increasingly important in managing HVAC systems. These technologies provide data for optimization and control.

Conclusion

In conclusion, floor duct systems are more than just conduits for air; they are integral components of modern building design. Their effective use hinges on a thorough understanding of design principles, installation techniques, and maintenance procedures. By following the guidelines presented here, you can confidently navigate the world of floor ducts and ensure optimal building ventilation and comfort.

The future of floor duct technology promises even greater efficiency and innovation

Quick FAQs: Floor Duct

What are the common materials used in floor duct construction?

Common materials include galvanized steel, aluminum, and fiberglass. The choice depends on factors like budget, insulation requirements, and the specific application.

How often should floor duct systems be inspected?

Regular inspections, typically annually, are recommended. However, more frequent checks may be necessary based on the building's use and environmental conditions.

What are the primary considerations for noise control in floor duct systems?

Soundproofing materials and strategic duct design are key. Careful attention to insulation and minimizing airflow turbulence are crucial steps to reduce noise transmission.

What are the typical dimensions for floor ducts in residential buildings?

Residential floor duct dimensions vary depending on the square footage and desired air circulation. Consult building codes and HVAC professionals for specific recommendations.

Recent posts

Electrical Wholesaler

SCHNAP is Australia's premier electrical wholesaler and electrical supplies, marketing thousands of quality products from leading brands. Trusted for nearly two decades by licensed electricians, contractors, and engineers, our range covers everything from basic electrical components to complex industrial electrical equipment

Top Electrical Wholesaler

Our key categories include: LED lighting, designer switches, commercial switchboards, circuit protection, security systems & CCTV, and smart home automation

Online Electrical Wholesaler

All products are certified to Australian standards (AS/NZS), backed by our 30-day, no-questions-asked return policy. Our expert technical team helps you quickly source the right solution for any residential, commercial, or industrial project, with daily dispatch from our Sydney electrical warehouse delivering Australia-wide

Best Electrical Supplies

SCHNAP offers the most comprehensive electrical product range, with full technical specifications, application details, installation requirements, compliance standards, and warranties — giving professionals total confidence in every purchase

Customer Support

Information

Contact Us

-

-

-

-

Mon - Fri: 6:30AM to 5:00PM

-

Sat: 8:00AM to 2:00PM

-

Sun: 9:00AM to 2:00PM

-

Jannali Branch:

-

-

Closed for Renovations

© 2004 - 2026 SCHNAP Electric Products