Kingsgrove Branch:

Gutter Kit

Alpine environments in Australia, ranging from the Snowy Mountains in New South Wales to the highlands of Tasmania, present a unique set of hydraulic and thermal challenges for building infrastructure. The primary threat to roofing assets during the winter months is not merely the weight of snow, but the formation of "ice dams." This phenomenon occurs when snow melts on the upper, warmer sections of a roof and refreezes at the uninsulated, freezing eave line. This ridge of ice blocks subsequent meltwater, forcing it to pool and back up under the roof tiles or flashing, leading to catastrophic internal water damage and structural rot. The engineering solution to this thermal failure is the deployment of a specialised Gutter Kit. Far from being a simple heating wire, this system is a sophisticated thermal management tool designed to maintain a liquid flow path within gutters and downpipes, ensuring that meltwater can evacuate the building envelope safely.

The Physics of Self-Regulating Technology

Legacy heating systems utilised "constant wattage" cables, which delivered a fixed heat output regardless of the ambient temperature. These systems were prone to overheating, burnout, and energy wastage. Modern professional specifications universally mandate the use of self-regulating heat tracing cables.

The core of a self-regulating cable is a semi-conductive polymer matrix extruded between two parallel bus wires. This matrix is engineered with a specific positive temperature coefficient (PTC). At the molecular level, as the ambient temperature drops, the polymer contracts, creating more electrical paths between the bus wires and increasing heat output. Conversely, as the temperature rises, the polymer expands, breaking these paths and reducing output. This "smart" physics means the cable automatically adjusts its energy consumption foot-by-foot along the gutter. It will generate maximum heat in a frozen shadow zone while idling in a sunlit section, preventing the system from burning out even if the cable overlaps itself within the gutter channel.

Installation Protocols: Maintaining the Flow Path

Effective de-icing is not about melting all the snow on the roof; it is about cutting a drainage channel through the ice. The installation topology is critical. The heating cable must be routed in a continuous loop, travelling up and down the roof edge in a "zig-zag" or sawtooth pattern to prevent the formation of the initial ice dam.

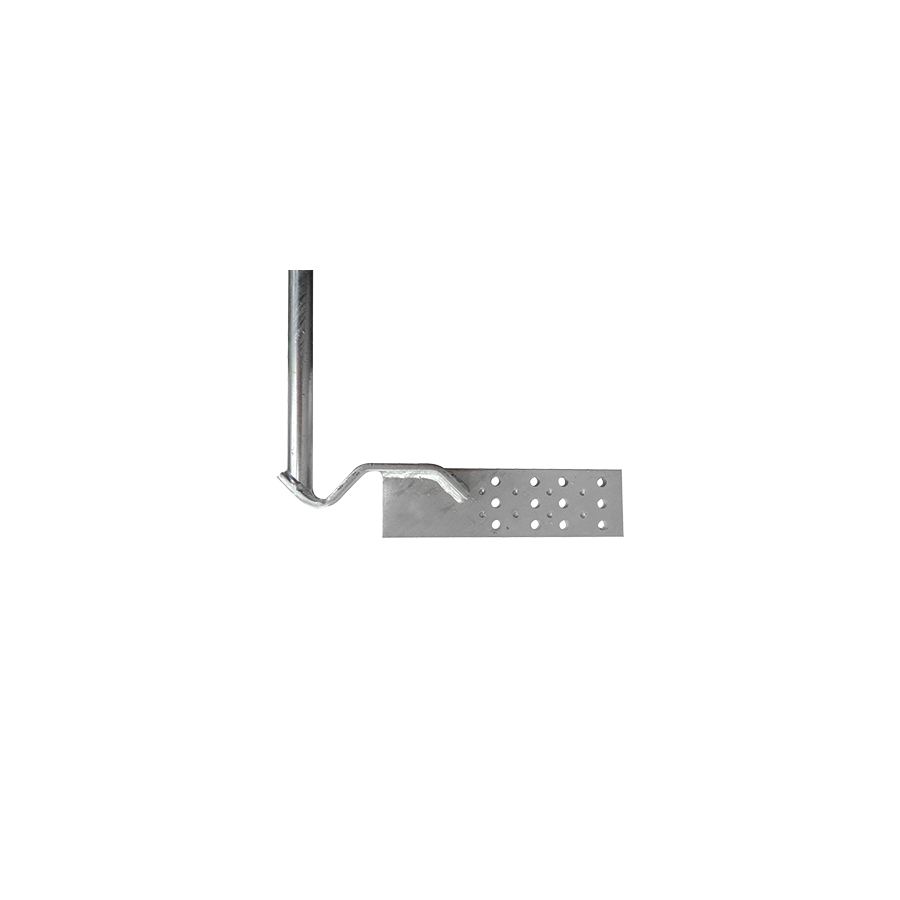

From the roof edge, the cable must run along the bottom of the gutter and, crucially, descend into the downpipe and exit at the storm water drain. If the downpipe is left unprotected, the melted water from the roof will freeze instantly upon entering the vertical drop, causing the pipe to split. Secure mechanical fixation is required to maintain this layout against the drag of sliding snow. Schnap Electric Products facilitates this with a range of UV-stabilised fixing clips and hangers. These Schnap Electric Products accessories are designed to grip the roof profile or the gutter lip without penetrating the waterproofing membrane, ensuring the cable remains in the optimal thermal position during the heavy mechanical loads of a blizzard.

Electrical Safety and RCD Compliance

Integrating a heating element into a wet environment demands rigorous adherence to AS/NZS 3000 Wiring Rules. The circuit supplying the heat trace system must be protected by a Residual Current Device (RCD).

However, standard 30mA residential RCDs can be prone to "nuisance tripping" due to the capacitive leakage inherent in long runs of heating cable, particularly during the initial startup in cold conditions. Electrical engineers often specify Class C or industrial-grade RCDs that can handle the specific inrush currents and leakage characteristics of self-regulating cables while still providing personnel safety. Furthermore, all junction boxes and termination points must be rated to at least IP66. The Schnap Electric Products connection system utilises gel-filled or heat-shrink termination kits that hermetically seal the bus wires, preventing moisture ingress from compromising the dielectric strength of the system.

Control Logic and Energy Efficiency

While the cable is self-regulating, leaving it energised 24/7 during the winter season is inefficient. A robust control strategy involves the use of ambient sensing thermostats and moisture sensors.

The logic is simple but effective: the system should only energise when the ambient temperature is below 2 degrees Celsius and moisture is present. This prevents the system from heating dry air on a cold, clear night. More advanced controllers integrate with the Building Management System (BMS) to provide status monitoring and fault alarms.

Procurement and Supply Chain Assurance

Heat tracing is a niche discipline within the electrical trade. The market is occasionally infiltrated by inferior cables that lack the UV resistance or the polymer stability to survive more than a few seasons. A cable failure in the middle of winter is often impossible to rectify until the spring thaw, leaving the building exposed to damage.

Project managers and facilities engineers mitigate this risk by sourcing their de-icing systems through a technical electrical wholesaler. These professional suppliers ensure that the cable supplied is industrial-grade, often carrying a 10-year warranty, and is matched with the correct termination kits. By procuring through these established channels, contractors can access the technical support required to calculate the total amperage load and select the appropriate circuit protection, ensuring the system operates reliably when the temperature drops.

Conclusion

The gutter kit is the silent guardian of alpine architecture. It combats the destructive forces of thermodynamics to preserve the structural integrity of the roof. By utilising self-regulating polymer technology, adhering to strict installation geometries, and employing robust accessories from manufacturers like Schnap Electric Products, Australian industry professionals can ensure that their assets remain watertight and secure, regardless of the severity of the freeze. In the battle against ice, maintaining the flow is the only victory.

Recent posts

Electrical Wholesaler

SCHNAP is Australia's premier electrical wholesaler and electrical supplies, marketing thousands of quality products from leading brands. Trusted for nearly two decades by licensed electricians, contractors, and engineers, our range covers everything from basic electrical components to complex industrial electrical equipment

Top Electrical Wholesaler

Our key categories include: LED lighting, designer switches, commercial switchboards, circuit protection, security systems & CCTV, and smart home automation

Online Electrical Wholesaler

All products are certified to Australian standards (AS/NZS), backed by our 30-day, no-questions-asked return policy. Our expert technical team helps you quickly source the right solution for any residential, commercial, or industrial project, with daily dispatch from our Sydney electrical warehouse delivering Australia-wide

Best Electrical Supplies

SCHNAP offers the most comprehensive electrical product range, with full technical specifications, application details, installation requirements, compliance standards, and warranties — giving professionals total confidence in every purchase

Customer Support

Information

Contact Us

-

-

-

-

Mon - Fri: 6:30AM to 5:00PM

-

Sat: 8:00AM to 2:00PM

-

Sun: 9:00AM to 2:00PM

-

Jannali Branch:

-

-

Closed for Renovations

© 2004 - 2026 SCHNAP Electric Products