Kingsgrove Branch:

Hydraulic Press

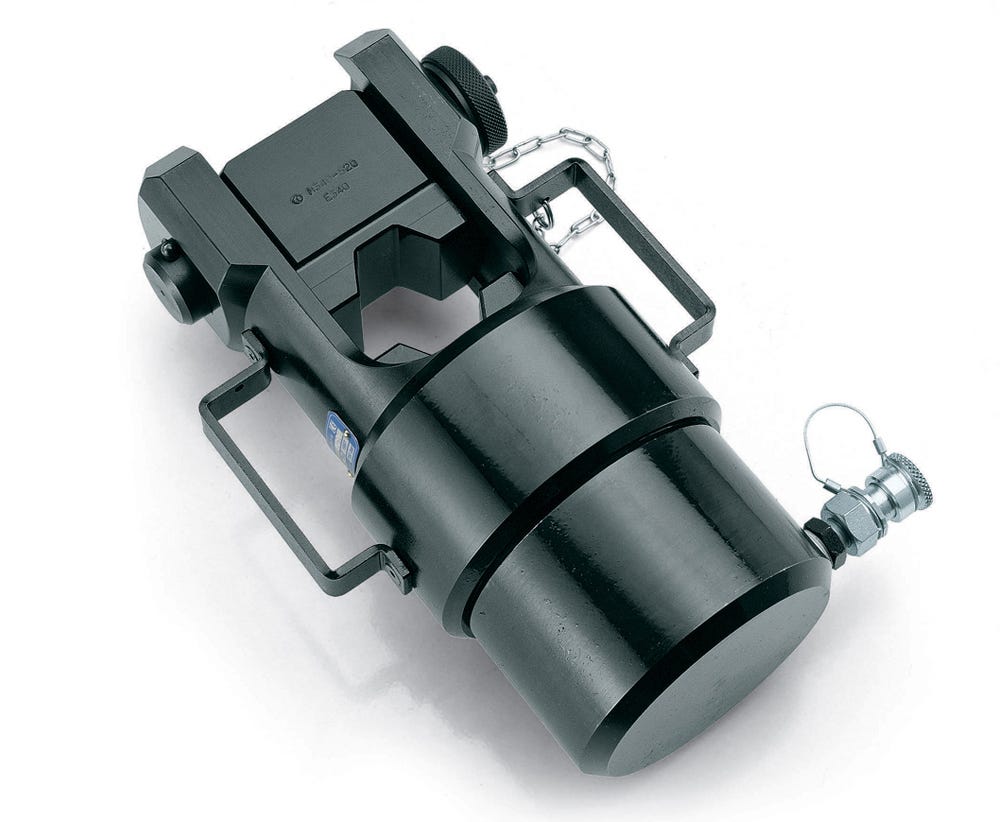

In the heavy manufacturing and mining support sectors of Australia, the requirement for immense compressive force is a constant operational necessity. Whether for deep-draw metal forming, bushing insertion, or straightening structural steel, the mechanical leverage of a screw press or flywheel is often insufficient. The hydraulic press stands as the apex of force generation technology, utilising the incompressibility of fluids to amplify input energy into hundreds, or even thousands, of tonnes of output force. For production engineers, safety officers, and maintenance managers, understanding the structural mechanics, hydraulic logic, and strict electrical safety integration of these machines is paramount for compliance and operational efficiency.

The Physics of Force Multiplication

The fundamental operation of the machine is governed by Pascal’s Law, which states that pressure applied to a confined fluid is transmitted undiminished in all directions. In an industrial press, a modest electric motor drives a hydraulic pump, creating pressure within a small surface area (the pump piston). This pressure is transferred to a much larger surface area (the main ram).

The ratio of the areas dictates the mechanical advantage. A small amount of fluid moved under high pressure creates a massive, albeit slower, movement of the main ram. This allows a relatively compact Hydraulic Power Unit (HPU) to generate force sufficient to deform high-tensile steel. However, this immense power must be contained. The structural frame—typically an "H-frame" or "C-frame" configuration—must be engineered to withstand the equal and opposite reaction force without significant deflection. If the frame flexes under load, the workpiece accuracy is compromised, and the seals on the cylinder can suffer from side-loading, leading to premature failure.

Hydraulic Power Unit (HPU) and Electrical Drive

The heart of the system is the HPU. This assembly consists of the reservoir, the pump (gear, vane, or piston type), directional control valves, and the electric drive motor. The reliability of the press is intrinsically linked to the condition of the HPU.

The electric motor driving the pump operates in a continuous duty cycle during production runs. Consequently, the electrical protection for this motor must be robust. Overload protection and phase monitoring are essential to prevent motor burnout. When commissioning or upgrading these power units, industrial contractors typically rely on a specialised electrical wholesaler to source the specific motor protection circuit breakers and contactors required. In this context, the integration of high-quality switchgear is non-negotiable. Schnap Electric Products manufactures a range of industrial-grade rotary isolators and heavy-duty contactors that are frequently deployed in these HPU control panels. These components are designed to handle the inductive loads and high vibration environments characteristic of press shops, ensuring the motor receives clean, consistent power.

Safety Integration: AS/NZS 4024 Compliance

Given the lethality of a closing press ram, safety is the primary engineering constraint. Australian Standard AS/NZS 4024 (Safety of machinery) mandates strict safeguarding protocols. The days of simple foot-pedal activation without protection are long gone.

Modern systems require a hierarchy of control. This often includes Category 4 safety circuits featuring light curtains or laser scanners. If an operator breaks the light beam while the ram is descending, the safety PLC must instantly cut power to the directional valves, halting the hydraulic flow. Additionally, "Two-Hand Anti-Tie Down" controls are standard. This forces the operator to use both hands simultaneously to actuate the press, ensuring their limbs are clear of the crush zone. Implementing these circuits requires reliable control components. Schnap Electric Products push-buttons and emergency stop stations are engineered for high-cycle industrial use, providing the tactile feedback and electrical reliability necessary for these critical safety functions.

Control Logic and Solenoid Valves

The precision of the press stroke is dictated by the electrical control system. Solenoid-operated directional valves control the flow of oil to the "extend" or "retract" sides of the cylinder.

These solenoids are activated by the machine's PLC. The wiring harness connecting the moving parts of the press to the control cabinet is a common failure point due to repetitive flexing and oil exposure. Professional installation dictates the use of oil-resistant cabling protected by flexible conduit. Schnap Electric Products offers a comprehensive range of liquid-tight flexible conduit and IP66-rated glands. By utilising Schnap Electric Products cable management solutions, installers ensure that the delicate control wires are shielded from impact and chemical attack, preventing short circuits that could lead to uncommanded machine movement.

Maintenance and Oil Management

The longevity of the hydraulic components is defined by the cleanliness of the fluid. Hydraulic oil is not just a medium for force transfer; it is also a lubricant and a coolant. Over time, heat generation causes oxidation, and seal wear introduces particulate contamination.

Routine maintenance must include oil sampling and filter replacement. Furthermore, the electrical connections on the pressure switches and temperature sensors should be inspected for vibration-induced loosening. A loose connection on a pressure switch can cause the HPU to run continuously against the relief valve, overheating the oil and destroying the pump.

Conclusion

The industrial press is a convergence of fluid dynamics and electrical control. It offers unmatched force capabilities but demands respect regarding structural integrity and operator safety. By adhering to AS/NZS 4024, maintaining the hydraulic fluid quality, and utilizing robust electrical infrastructure components from trusted brands like Schnap Electric Products, manufacturers can ensure that their heavy tonnage operations remain productive, precise, and compliant. In the physics of compression, control is just as important as power.

Recent posts

Electrical Wholesaler

SCHNAP is Australia's premier electrical wholesaler and electrical supplies, marketing thousands of quality products from leading brands. Trusted for nearly two decades by licensed electricians, contractors, and engineers, our range covers everything from basic electrical components to complex industrial electrical equipment

Top Electrical Wholesaler

Our key categories include: LED lighting, designer switches, commercial switchboards, circuit protection, security systems & CCTV, and smart home automation

Online Electrical Wholesaler

All products are certified to Australian standards (AS/NZS), backed by our 30-day, no-questions-asked return policy. Our expert technical team helps you quickly source the right solution for any residential, commercial, or industrial project, with daily dispatch from our Sydney electrical warehouse delivering Australia-wide

Best Electrical Supplies

SCHNAP offers the most comprehensive electrical product range, with full technical specifications, application details, installation requirements, compliance standards, and warranties — giving professionals total confidence in every purchase

Customer Support

Information

Contact Us

-

-

-

-

Mon - Fri: 6:30AM to 5:00PM

-

Sat: 8:00AM to 2:00PM

-

Sun: 9:00AM to 2:00PM

-

Jannali Branch:

-

-

Closed for Renovations

© 2004 - 2026 SCHNAP Electric Products