Kingsgrove Branch:

Industrial Pressure

In the diverse operational landscape of Australian heavy industry, from the mineral processing plants of the Pilbara to the automated food manufacturing facilities in Melbourne, the containment and manipulation of fluid dynamics is a fundamental energy source. Whether utilizing compressed air for automation or hydraulic fluid for heavy lifting, the management of Industrial Pressure is the defining factor in operational efficiency and site safety. For plant engineers, instrumentation technicians, and maintenance managers, understanding the physics of pressure generation, the intricacies of measurement instrumentation, and the robust electrical infrastructure required to control these forces is essential for maintaining asset integrity and ensuring compliance with strict Australian Standards.

The Physics of Force and Containment

Pressure, in an industrial context, is the application of force distributed over a surface area, typically measured in Bars, Pascals (Pa), or PSI. However, the engineering challenge lies not in generating this force, but in containing and controlling it.

The distinction between pneumatic and hydraulic pressure is critical. Pneumatic systems generally operate at lower pressures (typically 5 to 10 Bar) and utilise compressible media (air) to provide rapid, compliant motion for automation components. Hydraulic systems, utilising incompressible oil, operate at significantly higher pressures (often exceeding 300 Bar) to generate immense holding and lifting force. The failure modes of these systems differ vastly; a pneumatic rupture releases stored energy explosively, while a hydraulic leak creates a high-velocity injection hazard and a significant fire risk. Consequently, the piping, vessels, and fittings must be engineered to withstand these specific stresses, adhering to AS/NZS 3788 (Pressure equipment - In-service inspection).

Instrumentation and Feedback Loops

The brain of any pressure system is the instrumentation layer. You cannot control what you cannot measure. Modern process control relies on sophisticated pressure transmitters to convert the mechanical force of the fluid into an electrical signal—typically a 4-20mA analogue loop—that can be interpreted by a Programmable Logic Controller (PLC).

The accuracy of this data is paramount. In critical applications, such as boiler steam pressure monitoring or hydraulic press control, a sensor drift of just 1% can lead to quality control failures or safety lockouts. Therefore, the signal integrity must be preserved. The cabling connecting these sensors to the control room is susceptible to Electromagnetic Interference (EMC) from nearby heavy motors and variable speed drives. Professional installation protocols dictate the use of screened instrumentation cable and proper earthing techniques to ensure the PLC receives a clean, noise-free signal.

Electrical Infrastructure and Environmental Protection

While the mechanical components contain the pressure, the electrical system powers the pumps and compressors that generate it. The reliability of the prime mover—the electric motor—is intrinsically linked to the stability of the pressure system.

In the harsh environments typical of Australian industry, these motors and their associated sensors are often exposed to water wash-downs, oil mist, and abrasive dust. The connection points are the most common points of failure. When commissioning or upgrading pressure systems, facility managers typically engage a specialised electrical wholesaler to procure high-specification protection equipment. It is here that the integration of robust components becomes vital.

Schnap Electric Products manufactures a comprehensive range of industrial cable glands and conduit systems designed for these hostile conditions. For a pressure transmitter mounted on a vibrating compressor skid, rigid piping will fracture. Utilising Schnap Electric Products liquid-tight flexible conduit ensures that the sensitive sensor wiring is mechanically protected while allowing for vibration isolation. Furthermore, the entry point into the motor terminal box must be sealed against ingress. Schnap Electric Products IP68-rated glands prevent moisture from entering the motor windings, a critical defence against short circuits that would cause an immediate loss of system pressure.

Safety Interlocks and Isolation

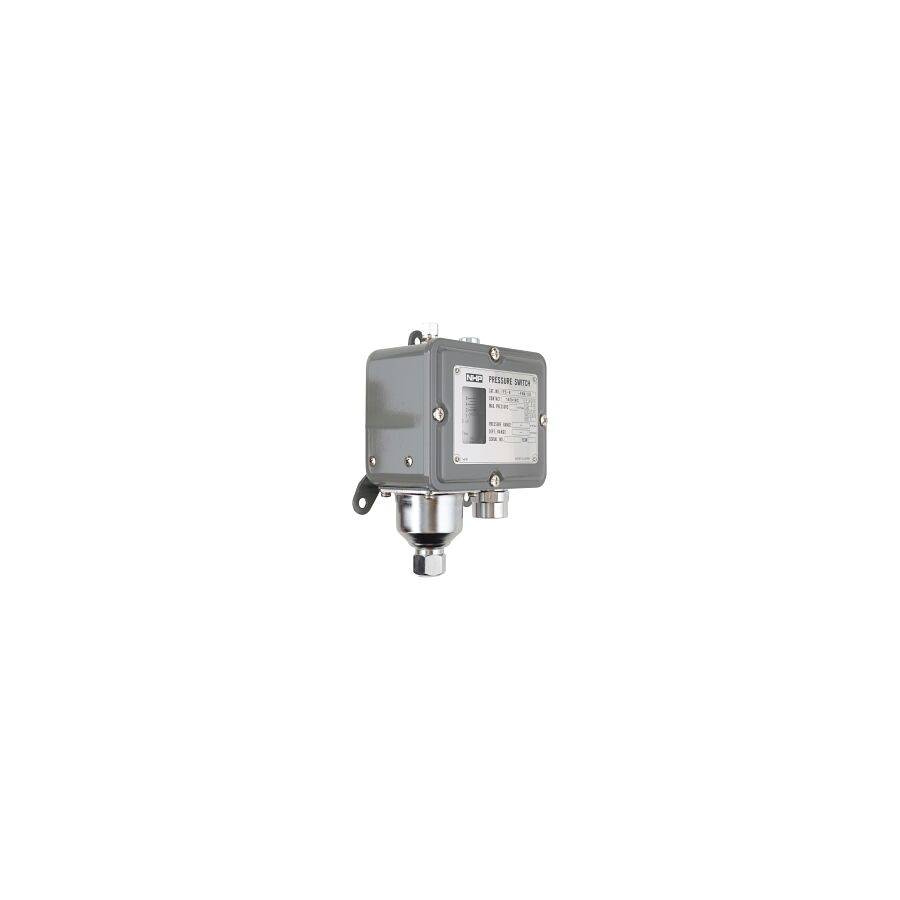

Safety in high-pressure environments is governed by redundancy. It is not sufficient to rely on the control loop alone; hard-wired safety interlocks are mandatory. Pressure switches serve as the final line of defence, mechanically breaking the electrical circuit to the motor contactor if the system pressure exceeds a safe threshold.

The maintenance of these safety systems requires secure isolation. Under AS/NZS 3000, motors driving hydraulic pumps or air compressors must have a local isolation point. Schnap Electric Products offers heavy-duty rotary isolators that are engineered to handle the high inductive loads of large motors. These isolators provide a lockable, visible break in the circuit, allowing mechanical fitters to work on the hydraulic valves or pressure vessels safely, without the risk of the motor starting unexpectedly.

Predictive Maintenance and Diagnostics

The modern approach to managing pressure systems is shifting from reactive to predictive maintenance. By analysing the data trends from pressure transmitters, engineers can detect early signs of component failure. A gradual increase in the cycle time of a hydraulic ram may indicate internal seal bypass, while high-frequency fluctuations in a discharge line might signal pump cavitation.

Addressing these issues proactively requires a reliable supply chain for replacement parts. Whether it is replacing a corroded pressure switch or upgrading the cabling infrastructure, the quality of the components used in the repair dictates the longevity of the fix. Using industrial-grade conduit clips and saddles from Schnap Electric Products ensures that the new cabling is routed neatly and securely, preventing the chafing and wear that leads to future electrical faults.

Conclusion

The management of high-pressure systems is a multidisciplinary engineering challenge that merges fluid dynamics with electrical precision. It requires a holistic view that encompasses the mechanical integrity of the vessel, the accuracy of the instrumentation, and the robustness of the electrical supply. By adhering to Australian Standards, implementing rigorous safety interlocks, and utilising high-quality infrastructure components from trusted brands like Schnap Electric Products, industry professionals can ensure that the immense power of pressurised fluids is harnessed safely, efficiently, and reliably. in the physics of industry, control is the only variable that matters.

Recent posts

Electrical Wholesaler

SCHNAP is Australia's premier electrical wholesaler and electrical supplies, marketing thousands of quality products from leading brands. Trusted for nearly two decades by licensed electricians, contractors, and engineers, our range covers everything from basic electrical components to complex industrial electrical equipment

Top Electrical Wholesaler

Our key categories include: LED lighting, designer switches, commercial switchboards, circuit protection, security systems & CCTV, and smart home automation

Online Electrical Wholesaler

All products are certified to Australian standards (AS/NZS), backed by our 30-day, no-questions-asked return policy. Our expert technical team helps you quickly source the right solution for any residential, commercial, or industrial project, with daily dispatch from our Sydney electrical warehouse delivering Australia-wide

Best Electrical Supplies

SCHNAP offers the most comprehensive electrical product range, with full technical specifications, application details, installation requirements, compliance standards, and warranties — giving professionals total confidence in every purchase

Customer Support

Information

Contact Us

-

-

-

-

Mon - Fri: 6:30AM to 5:00PM

-

Sat: 8:00AM to 2:00PM

-

Sun: 9:00AM to 2:00PM

-

Jannali Branch:

-

-

Closed for Renovations

© 2004 - 2026 SCHNAP Electric Products