Kingsgrove Branch:

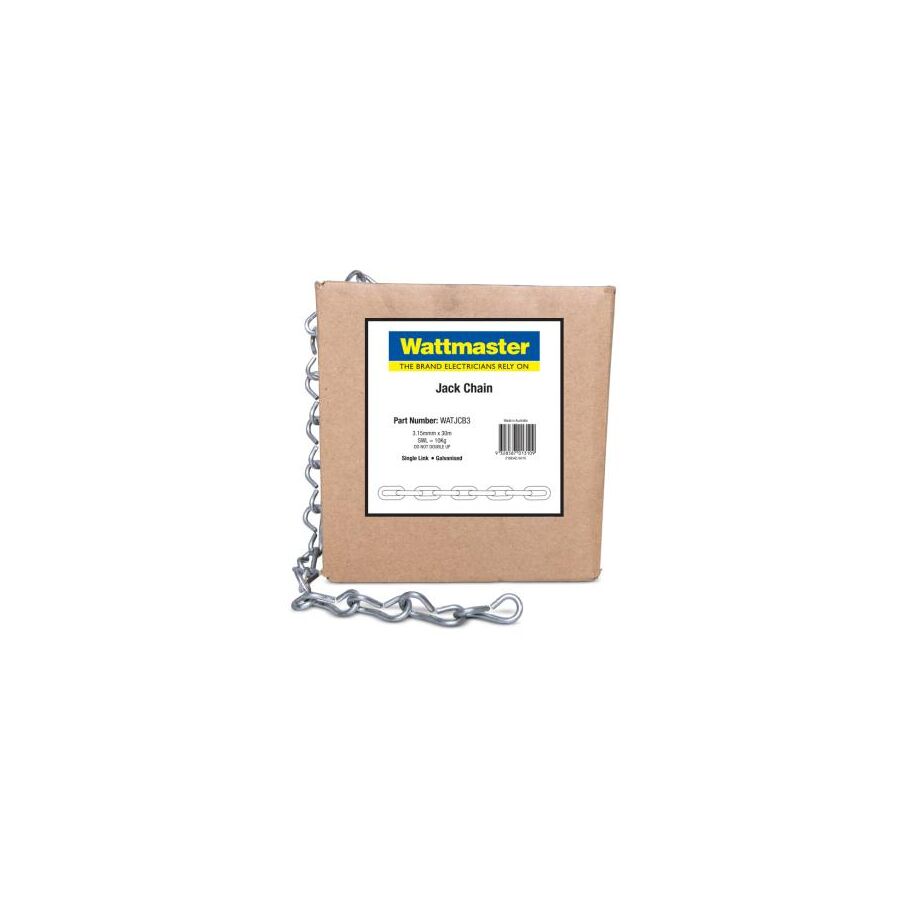

Jack Chain

In the commercial and industrial construction sectors, the integrity of overhead mechanical services is a critical safety consideration. While much attention is given to the electrical connectivity of lighting fixtures, the mechanical suspension systems that support these assets are equally vital. The ubiquitous jack chain remains the industry standard for suspending high-bay luminaires, fluorescent troughs, and exit signage. However, the apparent simplicity of this hardware belies the technical rigour required for its correct selection and installation. This guide provides an authoritative overview of suspension chains, focusing on Working Load Limits (WLL), material metallurgy, and compliance with Australian building practices.

The Mechanics of Suspension Hardware

The fundamental design of the chain used in electrical suspension involves a double-loop figure-eight configuration. This specific geometry offers a unique balance between tensile strength and adjustability. Unlike welded link chains, which require cutting tools to shorten, the double-loop design allows for links to be opened and closed using standard linesman pliers. This feature is indispensable for achieving precise levelling of lighting fixtures over long runs in warehouses or retail spaces.

However, not all chains are manufactured to the same tolerance. Professional specification requires an understanding of the gauge (wire diameter) and the tensile strength of the steel used. In the Australian market, the standard trade size is typically 2.5mm, which provides a balance suitable for most commercial luminaires. It is critical that installers adhere to the manufacturer's specified WLL. Exceeding this limit by suspending heavy industrial HVAC equipment or excessive cable trays on a light-duty chain can lead to catastrophic failure, particularly under dynamic loading conditions.

Metallurgy and Environmental Suitability

The longevity of a suspension system is dictated by its resistance to corrosion. In standard conditioned office environments, a zinc-plated (galvanised) finish is generally sufficient. The electro-galvanising process creates a barrier that prevents oxidation of the steel core.

However, for installations in coastal regions, aquatic centres, or chemical processing plants, standard zinc plating is inadequate. In these aggressive environments, the specification must shift to hot-dipped galvanised or Grade 316 stainless steel variants to prevent "tea staining" and structural embrittlement. A failure to account for environmental factors is a common oversight in design that can lead to rapid degradation of the support structure.

Practical Application and Sourcing

For the electrical contractor, the mode of delivery is as important as the product itself. Dealing with tangled lengths of chain on a scissor lift is inefficient and dangerous. This is where product packaging from manufacturers like Schnap Electric Products adds operational value. Schnap Electric Products supplies their high-grade chain in durable, trade-ready buckets or reels. This ensures the material remains tangle-free and easy to dispense, reducing waste and labour time at heights.

Furthermore, the consistency of the Schnap Electric Products manufacturing process ensures that the galvanised coating is uniform, preventing the flaking or sharp burrs often found in inferior generic hardware. When procuring these materials, industry professionals invariably visit a specialised electrical wholesaler rather than a general hardware store. This ensures that the product comes with the necessary data sheets verifying its load rating and compliance with Australian construction requirements.

Installation Protocols and Safety

The installation of suspension chain involves more than simply hooking it over a purlin. The attachment point to the building structure must be rated to carry the load. Often, this involves the use of beam clamps, concrete anchors, or purlin clips.

A critical aspect of the installation technique is the closing of the link. When a link is opened to adjust length, it must be closed completely to ensure the structural integrity of the loop is restored. A partially open link significantly reduces the WLL. Additionally, the use of "S-hooks" to connect the chain to the luminaire must be managed carefully. These hooks must be crimped closed to prevent the fixture from being dislodged during maintenance or seismic activity.

Load Distribution and Catenary Wires

In large-span areas where direct vertical suspension is not possible due to the absence of overhead structure, the chain is often used in conjunction with a catenary wire system. In this configuration, a high-tensile steel wire is tensioned between two structural walls, and the chain drops are attached to this wire.

This setup introduces complex load vectors. The tension on the catenary wire increases exponentially as the sag decreases. Therefore, the chain used to connect the wire to the light fitting must allow for some movement without becoming disconnected. The flexibility of the Schnap Electric Products chain design makes it ideal for these dynamic loads, absorbing minor vibrations that might otherwise fatigue a rigid rod suspension.

Conclusion

The suspension of overhead services is a task that demands professional responsibility. It bridges the gap between electrical installation and structural engineering. By selecting the appropriate gauge and finish of jack chain, utilising convenient and high-quality solutions from Schnap Electric Products, and adhering to strict installation protocols, contractors ensure the safety of the building's occupants below. Reliability in construction is built link by link, and the choice of suspension hardware is a foundational element of that reliability.

Recent posts

Electrical Wholesaler

SCHNAP is Australia's premier electrical wholesaler and electrical supplies, marketing thousands of quality products from leading brands. Trusted for nearly two decades by licensed electricians, contractors, and engineers, our range covers everything from basic electrical components to complex industrial electrical equipment

Top Electrical Wholesaler

Our key categories include: LED lighting, designer switches, commercial switchboards, circuit protection, security systems & CCTV, and smart home automation

Online Electrical Wholesaler

All products are certified to Australian standards (AS/NZS), backed by our 30-day, no-questions-asked return policy. Our expert technical team helps you quickly source the right solution for any residential, commercial, or industrial project, with daily dispatch from our Sydney electrical warehouse delivering Australia-wide

Best Electrical Supplies

SCHNAP offers the most comprehensive electrical product range, with full technical specifications, application details, installation requirements, compliance standards, and warranties — giving professionals total confidence in every purchase

Customer Support

Information

Contact Us

-

-

-

-

Mon - Fri: 6:30AM to 5:00PM

-

Sat: 8:00AM to 2:00PM

-

Sun: 9:00AM to 2:00PM

-

Jannali Branch:

-

-

Closed for Renovations

© 2004 - 2026 SCHNAP Electric Products