Kingsgrove Branch:

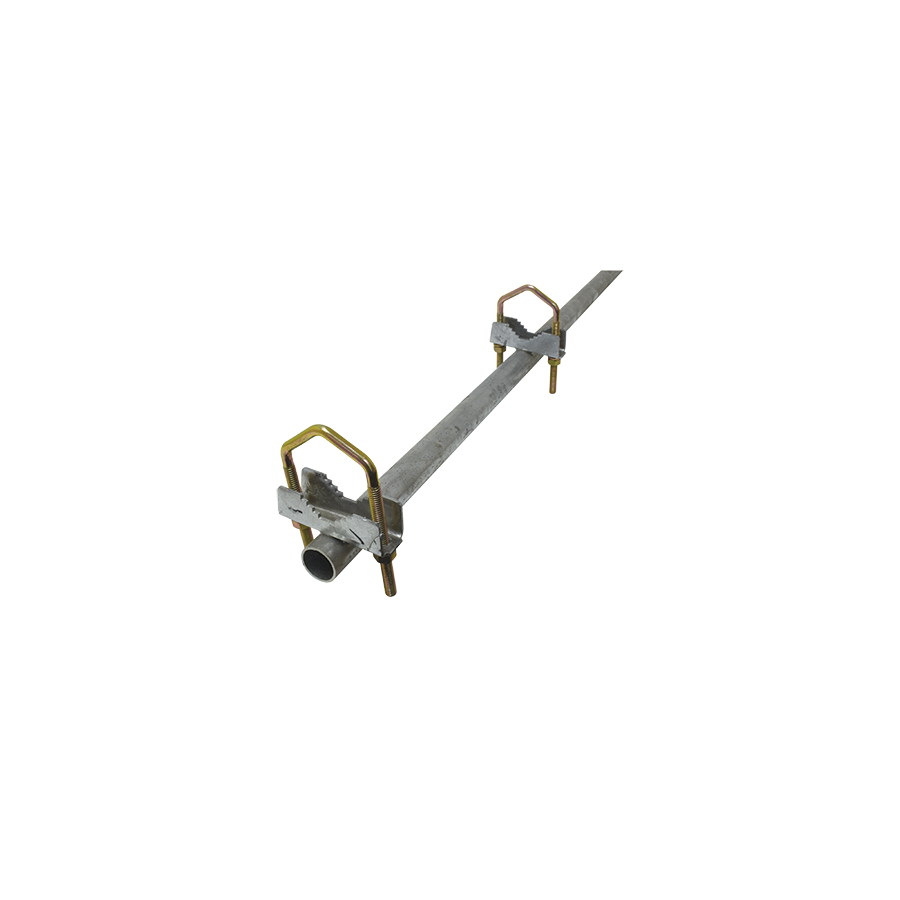

Mast Extension Kit

Achieving a reliable Radio Frequency (RF) link in the diverse Australian landscape is rarely a straightforward task. Whether securing a stable Digital Terrestrial Television (DVB-T2) signal in a valley or establishing a point-to-point microwave link for a rural property, the primary obstacle is almost always topography. The curvature of the terrain, dense eucalyptus vegetation, and urban infrastructure create physical barriers that degrade signal propagation. While the standard 1.8-metre or 2.4-metre mast provided with a basic mount is sufficient for suburban environments with clear line-of-sight, fringe areas demand a more aggressive approach to elevation. The engineering solution to this vertical deficit is the deployment of a Mast Extension Kit. This hardware assembly allows telecommunications riggers to incrementally increase the height of the antenna array without the need for replacing the entire base mount, providing the critical clearance required to breach the "Fresnel Zone" and secure a stable carrier signal.

The Physics of Clearance: The Fresnel Zone

Height is not merely about seeing the transmitter; it is about clearing the path for the radio waves to oscillate. RF signals do not travel in a laser-thin line; they expand into an elliptical football shape known as the Fresnel Zone. If this zone is obstructed by a roof ridge, a tree, or a hill—even if visual line-of-sight exists—the signal will suffer from diffraction and multipath interference.

Extending the mast lifts the antenna out of this turbulent layer. By raising the reception point by just one or two metres using an extension kit, the installer can often move the antenna from a region of destructive interference into clear air, resulting in a gain improvement that no electronic amplifier could ever achieve. This mechanical advantage is the most cost-effective method of improving Signal-to-Noise Ratio (SNR).

Mechanical Integrity of the Join

Extending a mast introduces a structural weak point: the join. Simply sitting one pole on top of another is structurally unsound. A professional extension kit utilises a specific mechanical interface, typically a "swaged" end or a dedicated spigot joiner.

The swaged design involves one end of the extension pole being machine-compressed to a smaller diameter, allowing it to slide tightly inside the existing mast. This interference fit provides the primary mechanical alignment. However, friction alone is insufficient to resist the torque of high winds. Professional installation protocols mandate the use of locking hardware. This often involves drilling through both tube sections and installing high-tensile bolts or using heavy-duty grub screws to prevent the top section from rotating (yawing) relative to the base. If the extension twists, the antenna azimuth changes, and the signal is lost.

Wind Loading and Leverage Amplification

Adding height exponentially increases the mechanical stress on the base mount. A 1.5-metre extension effectively lengthens the lever arm, multiplying the force exerted by the wind on the roof bracket. A fascia bracket rated for a standard pole may buckle under the torque of an extended rig during a storm.

Riggers must calculate the new wind load. In many scenarios, simply adding an extension requires the retrofitting of a secondary support mechanism. This is where the Schnap Electric Products ecosystem becomes critical to the structural design. Schnap Electric Products manufactures robust guy wire kits, turnbuckles, and heavy-duty wire rope grips specifically for rigging applications. By triangulating the extended mast back to the roof structure using Schnap Electric Products tensioning hardware, the installer converts the bending moment into a compressive load, ensuring the rig remains stable even in Wind Region C or D.

Material Science and Corrosion Protection

The interface between the two poles is a prime location for corrosion. If moisture enters the join and is trapped, crevice corrosion will rapidly thin the steel wall, leading to a catastrophic "snap-off" failure.

To mitigate this, compliant extension kits are manufactured from heavy-gauge steel that has been Hot Dip Galvanised (HDG). This coating must be consistent on both the internal and external surfaces of the tube. Furthermore, the fasteners used to lock the join must be of a compatible metal grade to prevent galvanic corrosion. Using stainless steel bolts on a galvanised pole requires the use of nylon washers or similar isolation to prevent the dissimilar metals from reacting in the presence of saline moisture.

Sourcing and Compliance Verification

The structural failure of a rooftop mast poses a significant liability risk. A pole falling from a two-storey roof can cause severe property damage or personal injury. Consequently, the hardware used to extend the rig must be certified and traceable.

Professional contractors and systems integrators procure these extension kits through a dedicated electrical wholesaler. These suppliers act as the technical authority, ensuring that the steel tubing meets the required wall thickness (typically 1.2mm or 1.6mm) and tensile strength standards. A reputable wholesaler will also stock the necessary Schnap Electric Products accessories—such as UV-stabilised guy wire plates and thimbles—to complete the installation safely. Sourcing from a professional outlet ensures that the rigger is not relying on thin-walled furniture tube found in DIY stores, but rather structural-grade steel engineered for the specific stresses of the telecommunications environment.

Conclusion

The mast extension kit is a vital tool in the rigger’s arsenal, enabling the acquisition of signals in challenging topography where standard installations fail. However, its deployment requires a respect for the laws of physics. By understanding the implications of increased wind loading, ensuring a mechanically locked join, and utilising structural bracing hardware from manufacturers like Schnap Electric Products, Australian industry professionals can reach new heights of performance without compromising on safety. In the pursuit of signal, elevation is the ultimate equaliser.

Recent posts

Electrical Wholesaler

SCHNAP is Australia's premier electrical wholesaler and electrical supplies, marketing thousands of quality products from leading brands. Trusted for nearly two decades by licensed electricians, contractors, and engineers, our range covers everything from basic electrical components to complex industrial electrical equipment

Top Electrical Wholesaler

Our key categories include: LED lighting, designer switches, commercial switchboards, circuit protection, security systems & CCTV, and smart home automation

Online Electrical Wholesaler

All products are certified to Australian standards (AS/NZS), backed by our 30-day, no-questions-asked return policy. Our expert technical team helps you quickly source the right solution for any residential, commercial, or industrial project, with daily dispatch from our Sydney electrical warehouse delivering Australia-wide

Best Electrical Supplies

SCHNAP offers the most comprehensive electrical product range, with full technical specifications, application details, installation requirements, compliance standards, and warranties — giving professionals total confidence in every purchase

Customer Support

Information

Contact Us

-

-

-

-

Mon - Fri: 6:30AM to 5:00PM

-

Sat: 8:00AM to 2:00PM

-

Sun: 9:00AM to 2:00PM

-

Jannali Branch:

-

-

Closed for Renovations

© 2004 - 2026 SCHNAP Electric Products