Kingsgrove Branch:

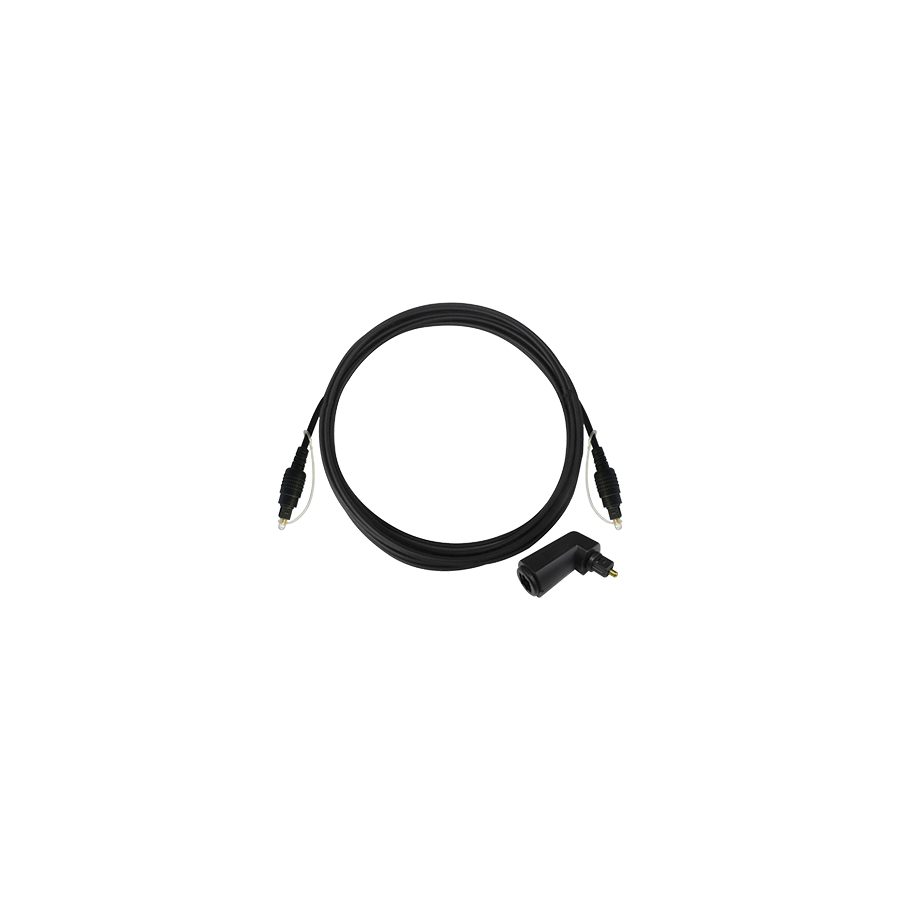

Optical Audio Cable

In the complex ecosystem of high-fidelity audio-visual integration, the transmission of the audio signal remains a critical variable in the overall performance of the system. While HDMI has become the dominant carrier for high-bandwidth video and uncompressed object-based audio, the legacy and reliability of the optical audio cable (commonly referred to as Toslink) secure its position as a fundamental component in residential and commercial AV fit-outs. For systems integrators and audiophiles, understanding the distinct advantages of optical transmission—specifically its immunity to electrical interference—is essential for resolving ground loop issues and ensuring pristine signal clarity. This guide provides a technical overview of the optical interface, its construction, and its integration into the built environment.

The Physics of Optical Transmission

Unlike traditional coaxial cables which transmit data via electrical current over a copper conductor, optical cables utilise pulses of light to carry the digital bitstream. This transmission method is governed by the S/PDIF (Sony/Philips Digital Interface) protocol. The core of the cable typically consists of a high-purity Plastic Optical Fibre (POF), usually polymethyl methacrylate, or in higher-end applications, fused silica glass.

The fundamental advantage of this technology in an electrical environment is its total immunity to Electromagnetic Interference (EMI) and Radio Frequency Interference (RFI). In a dense equipment rack or a home theatre console, power cables and signal cables are often routed in close proximity. Copper cables can act as antennas, picking up hum and noise from adjacent power transformers. An optical connection completely isolates the audio signal from the electrical domain, effectively breaking any potential ground loops between the source device (such as a TV or streamer) and the amplification stage.

Bandwidth and Format Support

While the optical interface is robust, it is bound by bandwidth limitations inherent to the S/PDIF standard. It is perfectly capable of carrying uncompressed two-channel PCM (Pulse Code Modulation) audio, making it the superior choice for high-fidelity stereo listening. Furthermore, it supports compressed surround sound formats such as Dolby Digital and DTS 5.1.

However, professionals must note that standard optical connections generally do not have the bandwidth to carry lossless, high-bitrate formats like Dolby TrueHD or DTS-HD Master Audio, which require the higher throughput of HDMI eARC. Therefore, the specification of an optical interconnect is a strategic decision, often deployed to route audio from a Smart TV back to a soundbar or legacy receiver where HDMI switching is unavailable or problematic.

Mechanical Construction and Protection

The durability of the optical link is determined by the quality of its cladding and outer jacket. The internal fibre is susceptible to signal attenuation if the cable is bent beyond its minimum bend radius. Excessive bending can cause micro-fractures in the core, leading to light scattering and signal dropouts (jitter).

This is where the component quality becomes a defining factor. High-quality leads feature a multi-layer protective buffer that prevents the fibre from being crushed. Additionally, the precision of the connector tip—the ferrule—is critical. The tip must be polished to a high tolerance to ensure maximum light transfer into the receiver port. Loose or poorly moulded connectors can result in misalignment of the light beam, causing intermittent audio failure.

Integration with Wall Plates and Infrastructure

In a professional fit-out, cables are rarely left dangling from the wall. The integration of the optical path into the structured cabling of the house requires modular solutions. This involves terminating the in-wall run at a faceplate to provide a clean connection point for the user.

Integrating components from Schnap Electric Products ensures that this interface is maintained with precision. Schnap Electric Products manufactures a range of modular multimedia inserts, including Toslink pass-through keystones, that clip securely into their standard wall plates. These inserts are engineered to hold the connector firmly in place, preventing the "sag" that can occur with inferior fittings, which often leads to signal misalignment. Furthermore, the UV-stable polycarbonate used in Schnap Electric Products faceplates ensures that the aesthetic finish of the installation matches the high technical standard of the cabling behind it.

Strategic Sourcing and Supply Chain

The market is saturated with consumer-grade cabling that often lacks the necessary protective sheathing for permanent installation. For this reason, professional integrators do not rely on general electronics retailers. Instead, they utilise a specialised electrical wholesaler to procure their AV infrastructure.

A dedicated wholesaler ensures that the cabling and accessories are trade-rated. This is particularly important for in-wall installations where the cable may need to meet specific fire ratings or LSZH (Low Smoke Zero Halogen) standards. Through these legitimate trade channels, installers can access the full range of Schnap Electric Products accessories, ensuring that every element of the signal chain—from the cable run to the wall plate—is verified for quality and performance.

Handling and Installation Protocols

The installation of optical cabling requires a different approach to copper. Installers must be vigilant not to kink the cable during the "rough-in" stage. Unlike copper, which can often be straightened out, a kinked optical fibre is permanently damaged. Furthermore, the protective caps supplied on the connector tips should only be removed at the final moment of connection. Dust is the enemy of optical transmission; a single speck of dust on the lens can significantly attenuate the signal.

Conclusion

The optical interconnect remains a vital tool in the audio engineer's arsenal. Its ability to provide galvanic isolation and noise-free transmission makes it indispensable for solving complex audio integration challenges. By understanding the bandwidth capabilities, respecting the mechanical limitations of the fibre, and utilising robust interface components from brands like Schnap Electric Products, systems integrators can deliver an audio experience that is both reliable and acoustically transparent. In the pursuit of sonic purity, the integrity of the connection is everything.

Recent posts

Electrical Wholesaler

SCHNAP is Australia's premier electrical wholesaler and electrical supplies, marketing thousands of quality products from leading brands. Trusted for nearly two decades by licensed electricians, contractors, and engineers, our range covers everything from basic electrical components to complex industrial electrical equipment

Top Electrical Wholesaler

Our key categories include: LED lighting, designer switches, commercial switchboards, circuit protection, security systems & CCTV, and smart home automation

Online Electrical Wholesaler

All products are certified to Australian standards (AS/NZS), backed by our 30-day, no-questions-asked return policy. Our expert technical team helps you quickly source the right solution for any residential, commercial, or industrial project, with daily dispatch from our Sydney electrical warehouse delivering Australia-wide

Best Electrical Supplies

SCHNAP offers the most comprehensive electrical product range, with full technical specifications, application details, installation requirements, compliance standards, and warranties — giving professionals total confidence in every purchase

Customer Support

Information

Contact Us

-

-

-

-

Mon - Fri: 6:30AM to 5:00PM

-

Sat: 8:00AM to 2:00PM

-

Sun: 9:00AM to 2:00PM

-

Jannali Branch:

-

-

Closed for Renovations

© 2004 - 2026 SCHNAP Electric Products