Kingsgrove Branch:

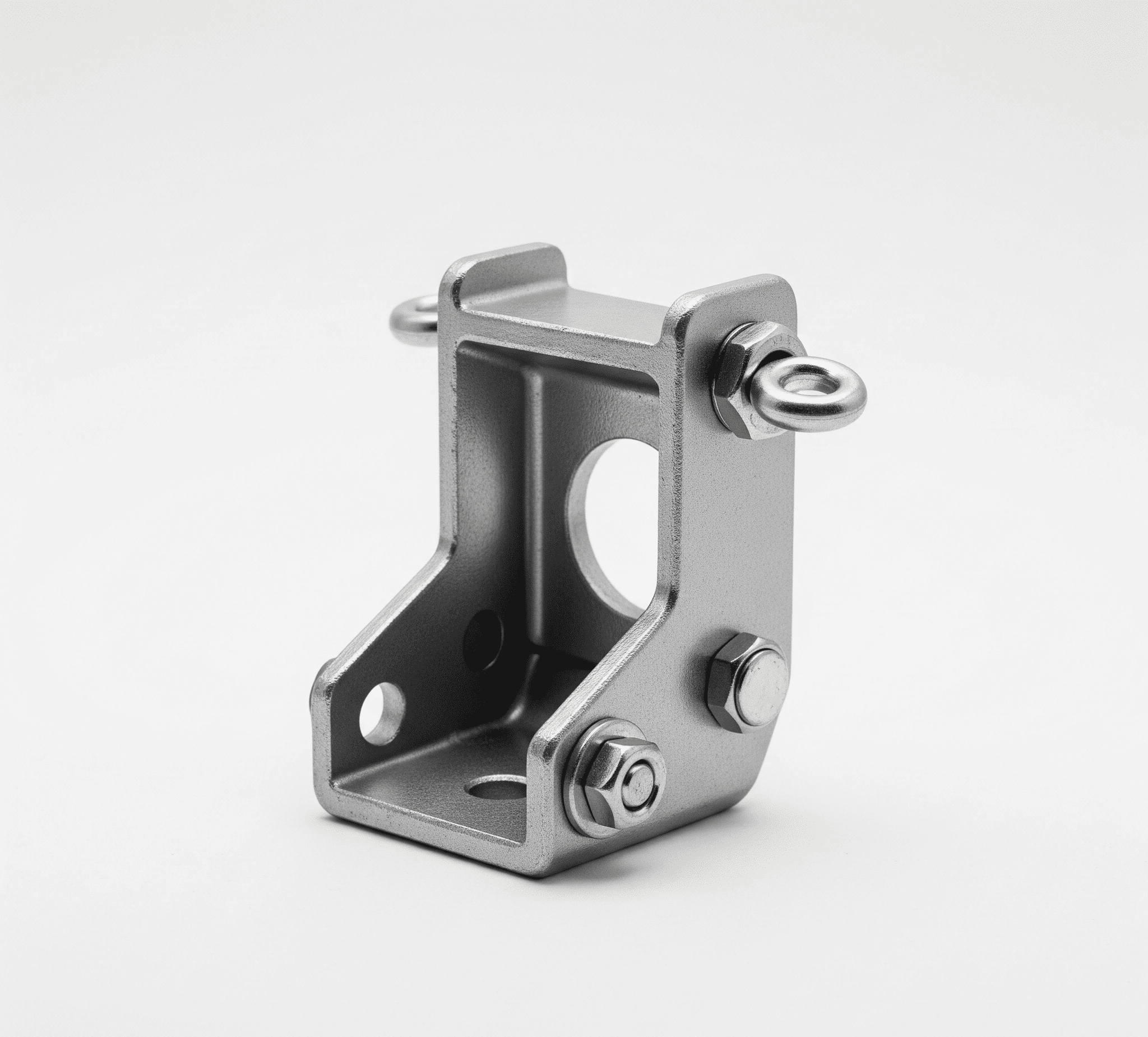

Point of Attachment Bracket

Point of attachment bracket, the unsung hero of countless structures, is a crucial component in various industries. From holding heavy machinery to securing delicate equipment, these brackets ensure stability and safety. Understanding their design, manufacturing, and application is key to utilizing them effectively

This guide delves into the world of point of attachment brackets, exploring their diverse types, critical design considerations, and essential maintenance procedures. We'll cover everything from material selection to safety protocols, ensuring a complete understanding for anyone working with these vital components

Point of Attachment Brackets: A Comprehensive Guide

Point of attachment brackets are crucial components in countless industrial applications. They provide a secure and reliable connection between different parts or structures, enabling various functionalities. Understanding their design, manufacturing, and applications is essential for ensuring structural integrity and safety

Introduction to Point of Attachment Brackets

Point of attachment brackets are essential components in a wide range of industries, from construction and manufacturing to aerospace and automotive. They act as the vital connection point between different parts or systems, transferring loads and forces safely. Different types of brackets cater to diverse needs, each engineered to handle specific load capacities and environmental conditions. Proper bracket selection is critical for maintaining structural integrity and preventing failures

- Definition and Function: Point of attachment brackets are structural elements designed to securely fasten components to a supporting structure. They distribute applied loads, ensuring the stability and safety of the connected parts. Their applications span various industries

- Types of Brackets: Brackets vary significantly based on material, design, and load capacity. Some common types include angle brackets, L-brackets, and U-brackets. These differ in shape, size, and the way they are attached to the supporting structure

- Importance of Selection: Choosing the correct bracket is paramount for safety and structural integrity. An inappropriate bracket can lead to failure, resulting in significant risks and potential damage. Factors like load specifications and environmental conditions must be meticulously considered

- Common Applications: Point of attachment brackets are found in machinery, furniture, automotive components, and more. Their use is fundamental in industries where structural stability and secure connections are essential

| Material | Typical Applications |

|---|---|

| Steel | Heavy machinery, structural support |

| Aluminum | Equipment mounting, light-duty applications |

| Composite | Pipe supports, electrical enclosures |

Design Considerations for Point of Attachment Brackets

Careful consideration of design factors is crucial for ensuring the bracket's ability to withstand intended loads and environmental conditions, see steel bush

- Load Specifications: Accurate load calculations are essential. This involves analyzing the forces acting on the bracket and ensuring it can safely handle these forces

- Material Properties: The strength, stiffness, and corrosion resistance of the chosen material are critical factors. Different materials perform differently under various loading conditions

- Environmental Conditions: Environmental factors like temperature fluctuations and exposure to corrosive elements can significantly affect the bracket's lifespan. Material selection must account for these factors

- Fastening Methods: The choice of fastening method affects the bracket's overall strength and stability. Bolts, rivets, and welds each have advantages and disadvantages depending on the specific application

###td

>td ###Durable, watertight

| Suitability for Bracket Type | Pros/Cons |

|---|---|

| Most bracket types | Versatile, adjustable |

| High-strength brackets | Strongest, permanent |

Manufacturing Processes and Materials, Point of attachment bracket

Manufacturing processes and material selection directly impact the bracket's performance and longevity

- Manufacturing Processes: Common methods include casting, forging, and machining. Each process offers different advantages in terms of precision, cost, and material utilization

- Material Selection: Steel, aluminum, and composites are common choices. Their properties, including strength, stiffness, and corrosion resistance, influence the bracket's suitability for specific applications

- Quality Control: Rigorous quality control measures are essential to ensure the bracket meets required standards and safety criteria

| Pros | Typical Applications |

|---|---|

| High strength, durability | Heavy-duty applications |

| Lightweight, corrosion resistance | Aerospace, automotive |

| Lightweight, high strength-to-weight ratio | High-performance applications |

Closing Notes

In conclusion, point of attachment brackets are more than just fasteners; they're the silent guardians of structural integrity. By carefully considering design, manufacturing, and installation procedures, we can maximize their performance and ensure safety in a wide range of applications. Remember, proper maintenance and adherence to safety standards are paramount to longevity and preventing potential hazards. This guide equips you with the knowledge needed to make informed decisions when working with these essential components

Quick FAQs: Point Of Attachment Bracket

What are the common materials used in point of attachment brackets?

Steel, aluminum, and composites are frequently used, each with its own strengths and weaknesses regarding load capacity, corrosion resistance, and cost

How do I choose the right bracket for my application?

Consider the load requirements, environmental conditions, and budget. Consult engineering specifications and refer to the material comparison table for guidance

What are the potential consequences of improper bracket installation?

Improper installation can lead to structural failure, safety hazards, and costly repairs. Always follow manufacturer instructions and safety protocols

What are some common maintenance tasks for point of attachment brackets?

Regular visual inspections for signs of wear and tear, corrosion, or damage, along with lubrication and cleaning, are crucial for long-term performance

Recent posts

Electrical Wholesaler

SCHNAP is Australia's premier electrical wholesaler and electrical supplies, marketing thousands of quality products from leading brands. Trusted for nearly two decades by licensed electricians, contractors, and engineers, our range covers everything from basic electrical components to complex industrial electrical equipment

Top Electrical Wholesaler

Our key categories include: LED lighting, designer switches, commercial switchboards, circuit protection, security systems & CCTV, and smart home automation

Online Electrical Wholesaler

All products are certified to Australian standards (AS/NZS), backed by our 30-day, no-questions-asked return policy. Our expert technical team helps you quickly source the right solution for any residential, commercial, or industrial project, with daily dispatch from our Sydney electrical warehouse delivering Australia-wide

Best Electrical Supplies

SCHNAP offers the most comprehensive electrical product range, with full technical specifications, application details, installation requirements, compliance standards, and warranties — giving professionals total confidence in every purchase

Customer Support

Information

Contact Us

-

-

-

-

Mon - Fri: 6:30AM to 5:00PM

-

Sat: 8:00AM to 2:00PM

-

Sun: 9:00AM to 2:00PM

-

Jannali Branch:

-

-

Closed for Renovations

© 2004 - 2026 SCHNAP Electric Products