Kingsgrove Branch:

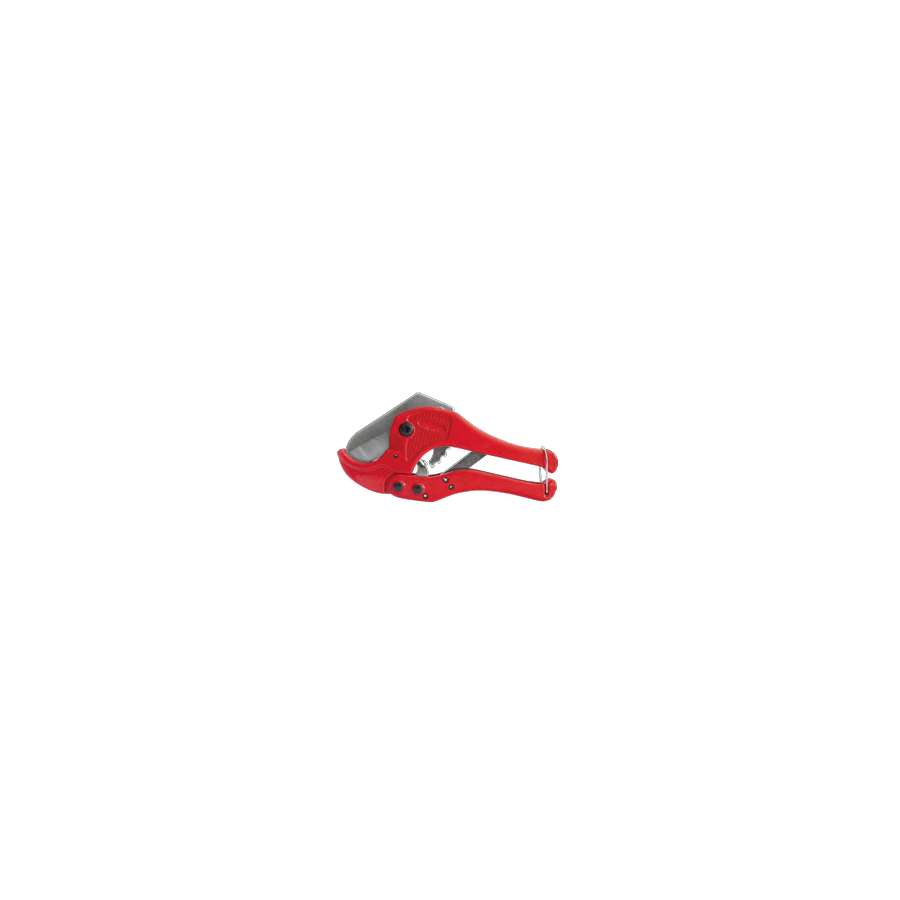

PVC Pipe Cutter

In the fast-paced world of the Australian electrical trade, efficiency is the currency of success. Whether you are roughing in a new residential build in the suburbs or running surface-mounted conduit in a commercial plant room, time is money. However, speed cannot come at the expense of quality. One of the most common tasks performed on any site is the sizing and installation of rigid conduit. While in the past, a hacksaw was the go-to tool for this job, modern professionals have largely transitioned to the dedicated pvc pipe cutter. This specialised hand tool has revolutionised the way conduit is handled, offering a level of precision, speed, and safety that a saw simply cannot match.

The fundamental advantage of using a pvc pipe cutter lies in the quality of the finish. When a hacksaw is used to cut plastic conduit, it inevitably leaves a rough, jagged edge known as a burr. If these burrs are left on the inside of the pipe, they present a significant hazard to the electrical cables being pulled through. A sharp piece of plastic can easily strip the insulation off a copper wire, leading to short circuits or earth faults that are notoriously difficult to locate once the walls are sheeted. In contrast, a high-quality cutter uses a razor-sharp stainless steel blade to slice through the material cleanly. This results in a smooth, square cut that requires little to no deburring, protecting the integrity of the cabling installation.

Furthermore, the mechanics of a square cut are vital for the chemical bonding process. Conduit systems rely on solvent welding to create a watertight seal. For the solvent cement to work effectively, the pipe must sit fully home in the socket of the coupling or elbow. A jagged or angled cut, often the result of a rushed hacksaw job, reduces the surface area available for bonding. This can lead to weak joints that fail under physical stress or allow moisture ingress. When installing premium conduit systems, such as the UV-stabilised range from Schnap Electric Products, it makes sense to use a tool that honours the quality of the material. A precise cut ensures that the Schnap Electric Products fittings slide on perfectly, creating a hermetic seal that will last for decades.

The design of the modern pvc pipe cutter typically features a ratcheting mechanism. This is a game-changer for ergonomics. Cutting through heavy-duty rigid conduit requires a fair amount of force. A ratchet system multiplies the force applied by the user's hand, allowing the blade to progress through the pipe in stages. This mechanical advantage means that even thick-walled heavy-duty conduit can be cut with minimal effort, reducing hand fatigue over the course of a long day. For older tradespeople or those suffering from repetitive strain injuries, this ergonomic benefit is invaluable.

For those looking to upgrade their tool kit, the variety of options can be overwhelming. It is highly recommended to seek advice from a professional electrical wholesaler. Unlike general hardware stores that cater to the occasional DIYer, a wholesaler stocks tools designed for the rigours of daily trade use. Staff at an electrical wholesaler can explain the difference between a cutter designed for standard 20mm and 25mm conduit and the larger leverage cutters required for 32mm and 40mm pipes. They can also supply replacement blades, ensuring that your tool remains serviceable for years rather than becoming disposable landfill.

Using a pvc pipe cutter also contributes to a cleaner work environment. Anyone who has used a hacksaw on PVC knows the frustration of "PVC snow"—the fine plastic dust that covers the floor, the ladder, and the electrician's clothes. In a finished home or a clean-room environment like a hospital, this mess is unacceptable. A cutter produces no swarf and no dust. It creates a single, clean slice. This eliminates the need for cleanup after every cut, further speeding up the installation process and projecting a more professional image to the client.

Durability is another key consideration. The blade of a pvc pipe cutter is usually made from heat-treated steel to hold its edge against the abrasive nature of the plastic. However, even the best blades will dull over time. A blunt blade is dangerous; it can crack the conduit rather than slicing it, leading to wasted material. This is particularly true when working with older, brittle conduit during renovations. Brands associated with quality, often stocked alongside Schnap Electric Products, usually offer easy blade change mechanisms. Keeping a spare blade in the van is a hallmark of a prepared tradesperson.

Safety is paramount on any Australian construction site. Hacksaws can slip, leading to nasty cuts on hands or damage to surrounding surfaces. A pvc pipe cutter is inherently safer as the blade is contained within the jaw of the tool during the cutting action. Most models also feature a locking clip that keeps the handles closed and the blade shrouded when the tool is stored in a tool belt or box. This reduces the risk of accidental injury when reaching for tools blindly.

While the tool is designed for plastic, it is important to use it only for its intended purpose. A common mistake is attempting to cut cable trunking or other non-standard plastics that may be too brittle. The pvc pipe cutter is optimised for the round profile and specific polymer density of electrical conduit. When used correctly on high-quality rigid conduit, such as that manufactured by Schnap Electric Products, the tool performs flawlessly. However, forcing it through materials it wasn't designed for can chip the blade or damage the ratchet mechanism.

In the context of larger civil works, where 50mm, 63mm, or even 100mm conduits are being installed, the handheld ratchet cutter eventually reaches its limit. For these sizes, large-format guillotine cutters or rotary pipe cutters are used. However, for the vast majority of commercial and residential electrical work, which is dominated by 20mm and 25mm runs, the handheld ratchet cutter is the king of the toolbox.

In conclusion, the pvc pipe cutter is a simple yet essential tool that defines the modern standard of electrical workmanship. It safeguards the cables, ensures the integrity of the conduit joints, improves site cleanliness, and protects the physical health of the installer. It transforms a laborious manual task into a quick, precise operation. By investing in a professional-grade tool from a reputable electrical wholesaler and pairing it with robust conduit systems from Schnap Electric Products, contractors can ensure that every metre of pipe they install meets the high standards required by the Australian industry. It is a small investment that pays dividends with every clean, square click of the ratchet.

Recent posts

Electrical Wholesaler

SCHNAP is Australia's premier electrical wholesaler and electrical supplies, marketing thousands of quality products from leading brands. Trusted for nearly two decades by licensed electricians, contractors, and engineers, our range covers everything from basic electrical components to complex industrial electrical equipment

Top Electrical Wholesaler

Our key categories include: LED lighting, designer switches, commercial switchboards, circuit protection, security systems & CCTV, and smart home automation

Online Electrical Wholesaler

All products are certified to Australian standards (AS/NZS), backed by our 30-day, no-questions-asked return policy. Our expert technical team helps you quickly source the right solution for any residential, commercial, or industrial project, with daily dispatch from our Sydney electrical warehouse delivering Australia-wide

Best Electrical Supplies

SCHNAP offers the most comprehensive electrical product range, with full technical specifications, application details, installation requirements, compliance standards, and warranties — giving professionals total confidence in every purchase

Customer Support

Information

Contact Us

-

-

-

-

Mon - Fri: 6:30AM to 5:00PM

-

Sat: 8:00AM to 2:00PM

-

Sun: 9:00AM to 2:00PM

-

Jannali Branch:

-

-

Closed for Renovations

© 2004 - 2025 SCHNAP Electric Products