Kingsgrove Branch:

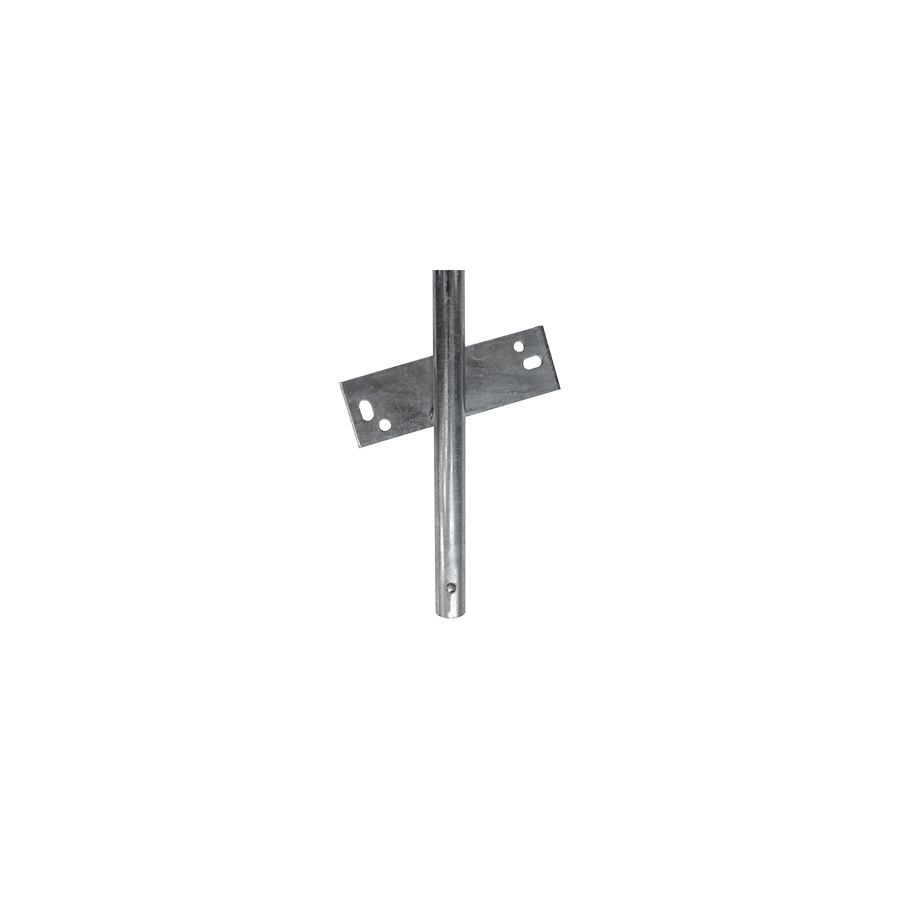

Rafter Mount

Secure telecommunications rigging begins below the roofline. While fascia brackets and tripod mounts are common, they often rely on secondary structural elements or surface friction to maintain stability. For heavy-duty installations, large UHF arrays, or satellite dishes where wind loading is a critical concern, directly coupling the mast to the building's primary frame is the superior engineering approach. The Rafter Mount facilitates this direct load transfer. By anchoring the mast support arm to the solid timber or steel truss of the roof structure, riggers eliminate the flex and fatigue associated with cosmetic fascia boards, ensuring that the installation remains plumb and secure even during the severe weather events characteristic of the Australian climate.

Structural Mechanics: Bypassing the Fascia

Residential fascia boards are frequently decorative. Often constructed from thin timber or lightweight metal, they are designed to hold guttering, not to resist the significant torsional and shear forces generated by a 3-metre mast in a gale. Anchoring a heavy load to a fascia can lead to twisting, paint cracking, or structural detachment.

Anchoring directly to the rafter moves the stress point. The rafter mount typically consists of a heavy-gauge steel riser that bolts through the roof covering (or passes between tiles) and attaches to the side or top of the rafter. This utilises the inherent compressive and tensile strength of the roof truss. For technicians, this method provides a "zero-flex" foundation. When the technician tightens the U-bolts, the mast is effectively part of the house frame, rather than an appendage hanging off the edge.

Penetration Management and Waterproofing

Penetrating the building envelope is the primary risk associated with this mounting topology. A rafter mount often requires a vertical riser to protrude through the roof tiles or metal sheet. If this penetration is not sealed correctly, water ingress will rot the insulation and damage the ceiling plaster.

Waterproofing protocols electrical involve the use of flexible dektites for metal roofs or lead/aluminium flashings for tile roofs. The riser must be positioned such that it does not impede water flow in the valley or cause debris damming behind the pole. Professional riggers will often shape a lead flashing sheet (typically 20kg grade) around the riser base, dressing it into the tile profile to create a permanent mechanical water barrier that outlasts silicone sealants.

Integration with Schnap Electric Products

The interface between the mount and the mast is a high-stress zone. Standard pressed-metal saddles often deform under high torque, leading to a loose mast that spins in the wind.

Schnap Electric Products addresses this connection integrity through their range of heavy-duty U-bolt assemblies and locking V-blocks. Specifically engineered for rigging applications, Schnap Electric Products hardware is manufactured from high-tensile steel designed to bite into the mast without crushing the tube. The V-block design provides two points of contact, significantly increasing the friction coefficient compared to a standard round saddle. Furthermore, using Schnap Electric Products hot-dipped galvanised pole caps ensures that the hollow mast does not become a reservoir for rainwater, preventing internal corrosion from compromising the system from the inside out.

Material Science: Hot Dip Galvanising

Corrosion resistance is non-negotiable on an Australian roof. The saline atmosphere in coastal cities and the intense UV radiation in the interior will rapidly degrade inferior metals. Electro-plated or "gold" zinc passivated brackets are insufficient for long-term external exposure.

Industry standards mandate the use of Hot Dip Galvanised (HDG) steel for all structural roof mounts. This process involves submerging the fabricated steel bracket into a bath of molten zinc at 450 degrees Celsius. The resulting metallurgical bond creates a sacrificial coating that is significantly thicker and more durable than cosmetic plating. This ensures that the rafter mount retains its structural mass and integrity for decades, matching the lifespan of the roof materials themselves.

Wind Regions and Load Ratings

Australia is divided into specific wind regions (A, B, C, and D) under AS/NZS 1170.2. A mount suitable for suburban Melbourne (Region A) may be catastrophically inadequate for Cyclonic North Queensland (Region C).

System design must account for the "sail area" of the antenna and the leverage exerted on the mount. A rafter mount inherently handles these loads better than fascia mounts due to the shorter lever arm and solid anchorage. However, for extreme heights, riggers must still calculate the bending moment. In some scenarios, a "stayed" installation is required, where the rafter mount acts as the base pivot, and guy wires provide lateral stability.

Sourcing and Supply Chain Integrity

Critical structural components should never be sourced from general hardware outlets where quality control is variable. Professional riggers and systems integrators procure these mounts through a specialised electrical wholesaler.

These professional suppliers act as the technical gatekeepers for the industry. They stock mounts that are certified for specific wind ratings and manufactured to precise tolerances. A wholesaler will typically carry the full suite of necessary components, from the rafter brackets and Schnap Electric Products U-bolts to the specific lead flashings required for the roof type. By sourcing via this legitimate supply chain, contractors ensure they are installing hardware that complies with Australian Standards, protecting both their reputation and the client's property.

Conclusion

The rafter mount represents the gold standard for structural antenna rigging. It prioritises mechanical integrity over ease of installation, providing a stable platform that isolates the load from the cosmetic elements of the building. By mastering the art of weatherproofing penetrations, insisting on hot-dip galvanised durability, and utilising precision clamping hardware from manufacturers like Schnap Electric Products, Australian industry professionals can deliver telecommunications infrastructure that stands firm against the elements. In the physics of rigging, the frame is the only foundation that matters.

Recent posts

Electrical Wholesaler

SCHNAP is Australia's premier electrical wholesaler and electrical supplies, marketing thousands of quality products from leading brands. Trusted for nearly two decades by licensed electricians, contractors, and engineers, our range covers everything from basic electrical components to complex industrial electrical equipment

Top Electrical Wholesaler

Our key categories include: LED lighting, designer switches, commercial switchboards, circuit protection, security systems & CCTV, and smart home automation

Online Electrical Wholesaler

All products are certified to Australian standards (AS/NZS), backed by our 30-day, no-questions-asked return policy. Our expert technical team helps you quickly source the right solution for any residential, commercial, or industrial project, with daily dispatch from our Sydney electrical warehouse delivering Australia-wide

Best Electrical Supplies

SCHNAP offers the most comprehensive electrical product range, with full technical specifications, application details, installation requirements, compliance standards, and warranties — giving professionals total confidence in every purchase

Customer Support

Information

Contact Us

-

-

-

-

Mon - Fri: 6:30AM to 5:00PM

-

Sat: 8:00AM to 2:00PM

-

Sun: 9:00AM to 2:00PM

-

Jannali Branch:

-

-

Closed for Renovations

© 2004 - 2026 SCHNAP Electric Products