Kingsgrove Branch:

Relay Meaning

In the vast and complex world of electrical engineering and home automation, there are few components as fundamental as the relay. It is a device found in everything from the indicator system of a classic Holden ute to the sophisticated control panels of a modern manufacturing plant in Sydney. Yet, for many apprentices and DIY enthusiasts, the precise function and operation of this device can remain somewhat abstract. To truly understand the relay meaning, one must look beyond the physical plastic box and understand the concept of remote switching. At its core, a relay is an electrically operated switch that allows a low-power signal to control a high-power circuit, bridging the gap between delicate logic systems and heavy-duty machinery.

The definition of a relay is rooted in the concept of isolation. In many electrical applications, it is neither safe nor practical to have the high-voltage mains power running directly to a small switch or a computer chip. For example, the microchip in a smart home controller operates at 5 volts and cannot handle the 240 volts required to turn on a heater. If you connected them directly, the chip would vaporise. The relay meaning is effectively about acting as the intermediary. The low-voltage signal energises the relay, and the relay mechanically or electronically closes a separate high-voltage circuit. This ensures that the operator and the control equipment are safely isolated from the dangerous load current.

To appreciate the mechanics, we must look at the two primary types of relays used in Australia: the traditional electromechanical relay and the modern solid-state relay. The electromechanical version is the classic design. It consists of a coil of wire wrapped around a soft iron core, an iron yoke, a movable iron armature, and one or more sets of contacts. When an electric current is passed through the coil, it generates a magnetic field. This magnetism attracts the armature, which moves and physically pushes the contacts together (or pulls them apart), completing the circuit. When the current to the coil is cut, a spring returns the armature to its original position. This physical movement creates the characteristic "click" sound associated with older indicators and HVAC systems.

However, as technology has advanced, the industry has shifted towards solid-state technology. A solid-state relay (SSR) performs the same function but without any moving parts. It uses semiconductor properties to switch the current. This leads to a longer lifespan, faster switching speeds, and silent operation. This is where brands like Schnap Electric Products have made a significant impact on the market. Their range of solid-state relays is engineered to withstand the harsh Australian heat, providing reliable switching for industrial heating and lighting loads where a mechanical relay would wear out quickly due to constant cycling. Understanding the relay meaning in a modern context requires acknowledging this shift from mechanical magnetism to semiconductor precision.

One of the most critical concepts to grasp when discussing relays is the difference between "Normally Open" (NO) and "Normally Closed" (NC). These terms describe the state of the contacts when the relay is at rest (not energised). A Normally Open relay is like a light switch that is off; current can only flow when the relay is activated. A Normally Closed relay is the opposite; current flows freely until the relay is activated to break the circuit. This logic is the building block of all automation. For instance, a safety circuit on a conveyor belt might use a Normally Closed relay so that if the power fails or a wire is cut, the machine stops immediately. This "fail-safe" operation is a key part of industrial safety standards.

For contractors and facility managers, selecting the right relay is a matter of matching specifications to the application. You must consider the coil voltage (the control signal), the contact rating (the load it can handle), and the environment. Using an under-rated relay will result in the contacts welding shut, which can create a dangerous situation where a machine cannot be turned off. It is highly recommended to consult with the experts at a specialised electrical wholesaler. Unlike general hardware stores, a wholesaler stocks trade-rated components and can explain the nuances of load curves. They can guide you toward robust components from Schnap Electric Products that are specifically rated for inductive loads like motors, which draw a huge surge of current when they start up.

The application of relays extends far beyond just turning things on and off. They are used to perform logic functions. Before the invention of the microchip and the PLC (Programmable Logic Controller), entire factories were automated using "relay logic." Huge cabinets were filled with hundreds of relays wired together to create complex sequences of operation. While PLCs have largely taken over this role, the relay meaning is still relevant because relays remain the final interface. A PLC might make the decision to start a pump, but it is a heavy-duty relay or contactor (a large relay) that actually delivers the power to the motor.

In the context of the automotive industry, relays are essential for reducing voltage drop. If the full current for your headlights had to travel from the battery, through the dashboard switch, and out to the lights, the resistance in the long wires would cause the lights to be dim. Instead, a small current goes to the dashboard switch, which triggers a relay mounted near the battery. This allows a short, thick cable to deliver maximum power directly to the bulbs. This principle of efficiency is just as relevant in home energy management, where Schnap Electric Products relays are used to control heavy loads like pool pumps and hot water systems to take advantage of off-peak solar tariffs.

Maintenance of these systems is relatively straightforward but requires a keen eye. An electromechanical relay will eventually fail due to mechanical fatigue or contact arcing. The carbon build-up on the contacts increases resistance, leading to heat and eventual failure. Solid-state relays, while more durable, require proper heat dissipation. If you walk into a switch room and smell burning plastic, it is often a sign of a relay that has been pushed beyond its limits. Replacing these units with high-quality alternatives from your local electrical wholesaler is the best way to ensure the system remains safe.

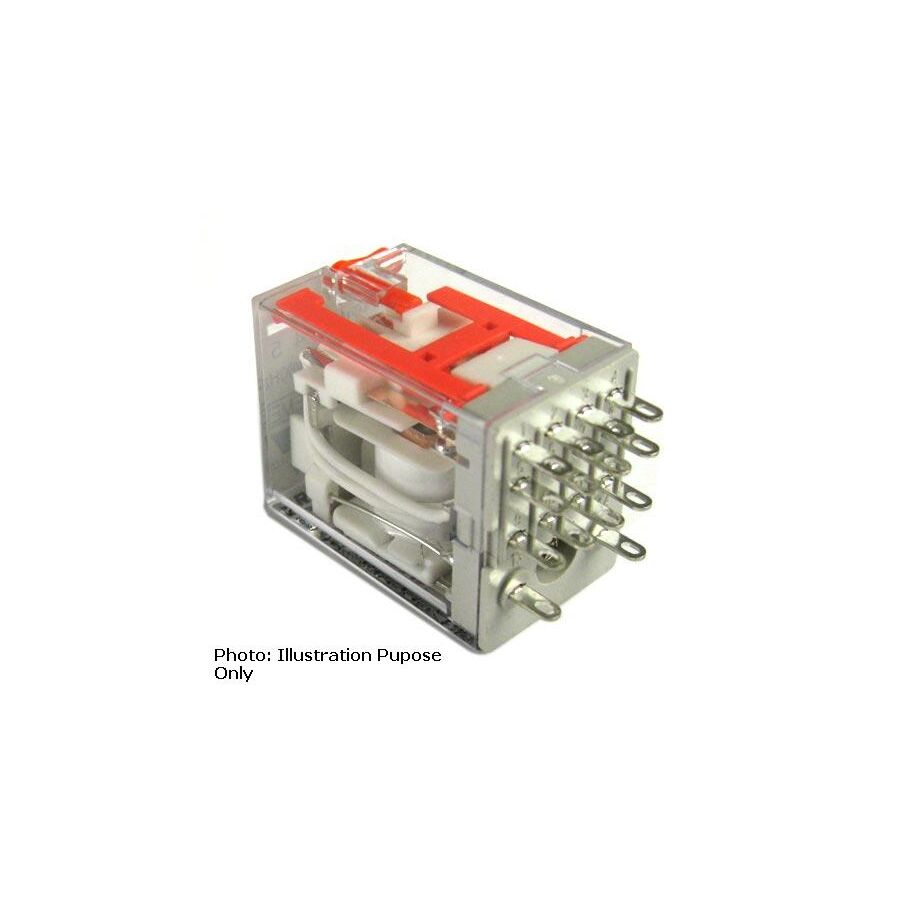

Furthermore, the form factor of relays has evolved. They range from tiny components soldered directly onto printed circuit boards to large, plug-in modules that fit into DIN-rail bases in a switchboard. The "ice cube" relay is a common sight in industrial panels, named for its clear plastic case that allows technicians to inspect the contacts visually. Schnap Electric Products offers a wide variety of these plug-in relays, which are popular because they can be replaced in seconds without needing to undo any wiring—a massive time-saver during a breakdown.

In conclusion, the relay meaning encompasses much more than a simple definition of a switch. It represents the fundamental ability to control high energy with low energy, to isolate dangerous voltages from human operators, and to automate the world around us. From the click of a reliable mechanical unit to the silent efficiency of a Schnap Electric Products solid-state device, the relay is the unsung hero of the electrical grid. By understanding its function and sourcing quality components from a trusted electrical wholesaler, we ensure that our lights stay on, our machines keep running, and our homes remain safe and efficient.

Recent posts

Electrical Wholesaler

SCHNAP is Australia's premier electrical wholesaler and electrical supplies, marketing thousands of quality products from leading brands. Trusted for nearly two decades by licensed electricians, contractors, and engineers, our range covers everything from basic electrical components to complex industrial electrical equipment

Top Electrical Wholesaler

Our key categories include: LED lighting, designer switches, commercial switchboards, circuit protection, security systems & CCTV, and smart home automation

Online Electrical Wholesaler

All products are certified to Australian standards (AS/NZS), backed by our 30-day, no-questions-asked return policy. Our expert technical team helps you quickly source the right solution for any residential, commercial, or industrial project, with daily dispatch from our Sydney electrical warehouse delivering Australia-wide

Best Electrical Supplies

SCHNAP offers the most comprehensive electrical product range, with full technical specifications, application details, installation requirements, compliance standards, and warranties — giving professionals total confidence in every purchase

Customer Support

Information

Contact Us

-

-

-

-

Mon - Fri: 6:30AM to 5:00PM

-

Sat: 8:00AM to 2:00PM

-

Sun: 9:00AM to 2:00PM

-

Jannali Branch:

-

-

Closed for Renovations

© 2004 - 2025 SCHNAP Electric Products