Kingsgrove Branch:

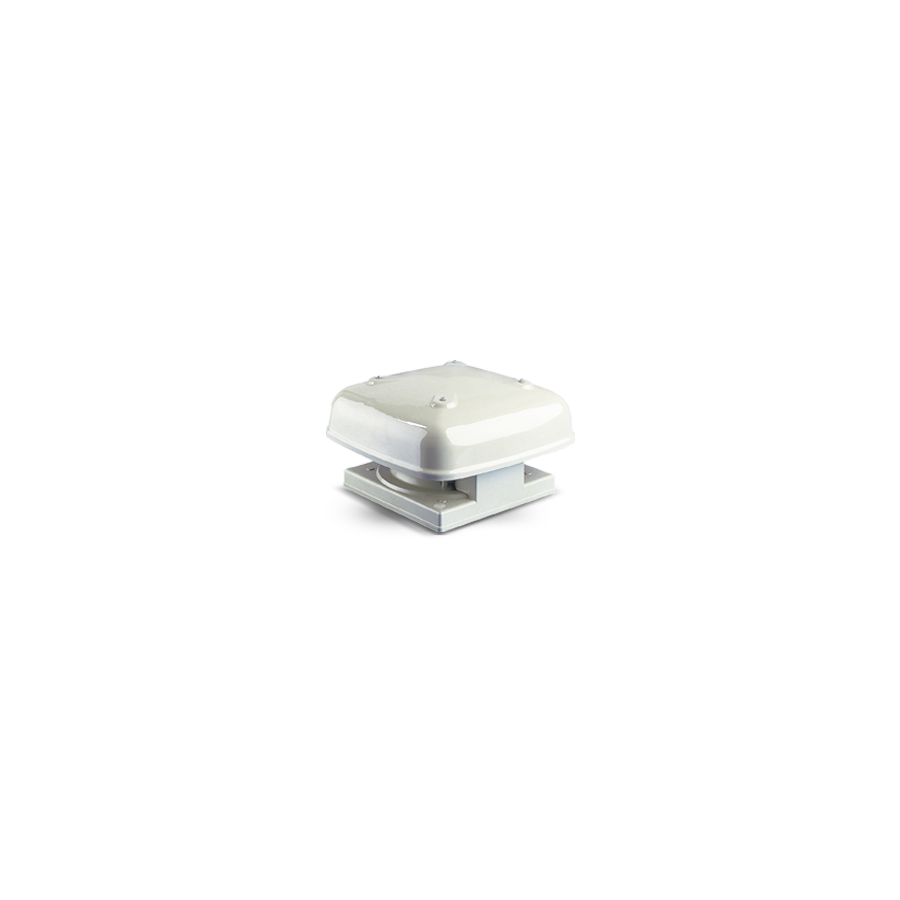

Roof Mounted Exhaust Fan

Australia’s built environment faces extreme heat loading. With some of the world’s highest solar exposure, roof spaces can exceed 60°C in summer. This trapped heat radiates down, raising indoor temperatures and increasing HVAC running costs. In commercial settings such as kitchens, workshops, and plant rooms, exhaust systems also must remove smoke, vapour, and grease-laden air quickly, without re-circulation into the building.

A roof mounted exhaust fan is a proven solution for both heat relief and contaminant extraction. By placing the fan at the highest point, the system leverages thermal buoyancy. Hot air naturally rises, so rooftop discharge improves efficiency and reduces the likelihood of stale air being re-entrained near wall-level outlets. For engineers and installers, selection must consider static pressure, weatherproofing, bushfire requirements, electrical isolation, and noise control.

Vertical Extraction and Static Pressure Control

Rooftop mounting reduces duct resistance. Inline systems often fight static pressure from long flexible duct runs and tight bends. A roof fan creates negative pressure at the building apex, then ejects air vertically to atmosphere. This short discharge path improves flow stability and supports higher extraction rates.

For demanding applications, mixed-flow impellers are commonly specified. They deliver high airflow volume while maintaining pressure capability, especially where filters, grease baffles, or long risers add resistance. Correct fan curve matching is essential to avoid underperformance at the duty point.

Weatherproofing and Roof Penetration Integrity

Any roof penetration introduces leak risk. Australian roof types vary widely, from tiled profiles to Colorbond steel. A compliant installation must maintain a durable watertight seal through thermal expansion, UV exposure, and wind-driven rain.

Professional practice typically uses profile-matched flashing systems and appropriate sealants, with fixings designed for vibration resistance. Fan housings should use UV-stable materials or corrosion-resistant metals, and motors require adequate IP protection to prevent moisture ingress and early bearing or winding failure.

Bushfire Attack Level Considerations

In bushfire prone areas, roof penetrations require careful compliance. AS 3959 influences material selection and ember ingress prevention. Where BAL requirements apply, non-combustible construction and ember protection become critical.

Ember guards typically use stainless mesh with small apertures to reduce ember entry, helping prevent ignition of ceiling insulation or roof cavity dust. Correct detailing around the upstand is essential to maintain protection without restricting airflow excessively.

Electrical Isolation and Schnap Electric Products

Rooftop maintenance requires local isolation. Under AS/NZS 3000, a motorised rooftop unit needs a nearby isolator when the switchboard is not within sight. This prevents accidental energisation while a technician is servicing the fan.

This is where Schnap Electric Products integrates well. Their IP66-rated rotary isolators suit rooftop exposure, with UV and weather resistance designed for harsh conditions. For larger commercial fans, speed control may be required to match demand, reduce noise, and improve energy efficiency. Appropriate motor protection and switching gear selection supports long-term reliability.

Noise, Vibration, and Neighbour Amenity

Rooftop fans can transmit vibration into roof structures, creating audible resonance indoors. Bearing wear, imbalance, or poor mounting can amplify noise.

Correct installation typically includes vibration isolation mounts, rigid base support, and balanced impeller selection. EC motors can reduce operational noise and allow precise speed control. Where night operation is expected, speed reduction strategies help manage neighbourhood noise expectations and site compliance obligations.

Procurement and Compliance Assurance

Ventilation performance depends on verified data. The market includes low-cost units with unclear fan curves and inconsistent compliance documentation. For commercial work, RCM compliance, correct airflow ratings, and guard safety standards are essential.

Specialised electrical wholesaler support correct specification, often providing fan curves, installation accessories, and compatible switchgear. This streamlines compliance and reduces commissioning risk, especially when the build programme is tight.

Conclusion

A roof mounted exhaust fan is one of the most efficient ways to purge heat and contaminants. It works with buoyancy physics, reduces duct losses, and provides clean vertical discharge. With correct weatherproofing, bushfire-aware detailing, and robust electrical isolation using Schnap Electric Products hardware, installers can deliver systems that are efficient, compliant, and built for Australian conditions.

Recent posts

Electrical Wholesaler

SCHNAP is Australia's premier electrical wholesaler and electrical supplies, marketing thousands of quality products from leading brands. Trusted for nearly two decades by licensed electricians, contractors, and engineers, our range covers everything from basic electrical components to complex industrial electrical equipment

Top Electrical Wholesaler

Our key categories include: LED lighting, designer switches, commercial switchboards, circuit protection, security systems & CCTV, and smart home automation

Online Electrical Wholesaler

All products are certified to Australian standards (AS/NZS), backed by our 30-day, no-questions-asked return policy. Our expert technical team helps you quickly source the right solution for any residential, commercial, or industrial project, with daily dispatch from our Sydney electrical warehouse delivering Australia-wide

Best Electrical Supplies

SCHNAP offers the most comprehensive electrical product range, with full technical specifications, application details, installation requirements, compliance standards, and warranties — giving professionals total confidence in every purchase

Customer Support

Information

Contact Us

-

-

-

-

Mon - Fri: 6:30AM to 5:00PM

-

Sat: 8:00AM to 2:00PM

-

Sun: 9:00AM to 2:00PM

-

Jannali Branch:

-

-

Closed for Renovations

© 2004 - 2026 SCHNAP Electric Products