Kingsgrove Branch:

Safety Harness

In the Australian construction and utilities sectors, the management of gravitational hazards is the single most critical aspect of Work Health and Safety (WHS). Falls from heights remain the leading cause of fatalities in the workplace. While the "Hierarchy of Control" prioritises the elimination of the hazard (such as working from the ground) or the use of passive engineering controls (such as guardrails), there are countless scenarios where these are not reasonably practicable. In these instances, the deployment of a Personal Fall Arrest System (PFAS) is mandatory. The core component of this system is the safety harness. For safety officers, site supervisors, and tradespeople, understanding the physiological design, material science, and inspection regimes of this equipment is not merely a box-ticking exercise; it is a matter of life and death.

Regulatory Framework: AS/NZS 1891

The design, manufacturing, and selection of fall protection equipment in Australia are strictly governed by the AS/NZS 1891 series. Specifically, AS/NZS 1891.1 outlines the requirements for harnesses and ancillary equipment. A compliant harness is designed to distribute the kinetic energy of a fall arrest across the strong structural points of the human body—the thighs, pelvis, chest, and shoulders—rather than the spine or abdomen.

This distribution is critical. In a free-fall event, the body generates massive force. If this force were concentrated on a waist belt (now prohibited for fall arrest), it would cause catastrophic internal injuries. The full-body design ensures that the user remains suspended in an upright position post-fall, facilitating a safer rescue operation.

Material Science and Dielectric Considerations

The standard industrial harness is constructed from high-tensile polyester webbing, chosen for its resistance to UV degradation and chemical attack. However, for specific trade applications, the material specification must change.

For professionals working on overhead lines or in substations, the risk is not just gravity; it is electricity. Standard harnesses feature steel D-rings and buckles which are conductive. In an arc flash event or accidental contact, these metal components can become a path to earth or cause secondary burns. Therefore, it is common practice for a specialist electrical wholesaler to stock specific "dielectric" harnesses. These units feature hardware coated in non-conductive PVC or manufactured from high-strength composites, ensuring that the PPE does not introduce an additional electrical hazard to the work environment.

Integration of Ancillary Equipment

A harness is rarely used in isolation. It is the attachment point for lanyards, pole straps, and tool tethers. The integration of these components must be seamless. Dropped objects pose a significant risk to personnel on the ground. To mitigate this, professionals utilise purpose-built tool retention systems.

This is where the integration of robust accessories from Schnap Electric Products becomes essential. The Schnap Electric Products range includes heavy-duty tool lanyards and equipment pouches that can be securely attached to the webbing loops of the harness. These accessories are engineered to withstand the dynamic load of a falling drill or multimeter, preventing it from becoming a lethal projectile. Furthermore, Schnap Electric Products offers specialised trauma straps (suspension relief straps) which can be retrofitted to the harness, providing a vital foothold for a suspended worker to alleviate pressure on the femoral arteries.

The Mechanics of Suspension Intolerance

Topical authority on fall protection requires a detailed discussion of Suspension Intolerance (formerly known as Suspension Trauma). When a worker is suspended motionless in a harness, the leg straps can compress the femoral veins, preventing blood from returning to the heart (venous pooling). This can lead to cerebral hypoxia and death in under 15 minutes.

The design of the harness plays a role in mitigating this. Premium harnesses feature "articulated" designs that allow for greater mobility and less restriction on the groin area. However, the primary control is the rescue plan. AS/NZS 1891.4 mandates that a rescue plan must be in place before any work at heights commences. Reliance on emergency services is not a compliant plan due to potential response delays.

Inspection and Maintenance Regimes

The reliability of the equipment is maintained through a rigorous inspection regime mandated by AS/NZS 1891.4. This involves two levels of checking:

- Pre-Start Check: The user must inspect the harness before every use. They are looking for cuts in the webbing, chemical burns, UV discolouration, and the integrity of the stitching (specifically the "fall indicator" stitches which rip open to show if the harness has previously sustained a shock load).

- Six-Monthly Inspection: A competent person (typically a certified height safety equipment inspector) must inspect the harness every six months. This inspection must be documented in a logbook.

Harnesses have a finite lifespan, typically recommended by manufacturers to be 10 years from the date of manufacture, provided they pass all inspections. However, harsh environments (mining, offshore oil and gas) may necessitate a much shorter service life.

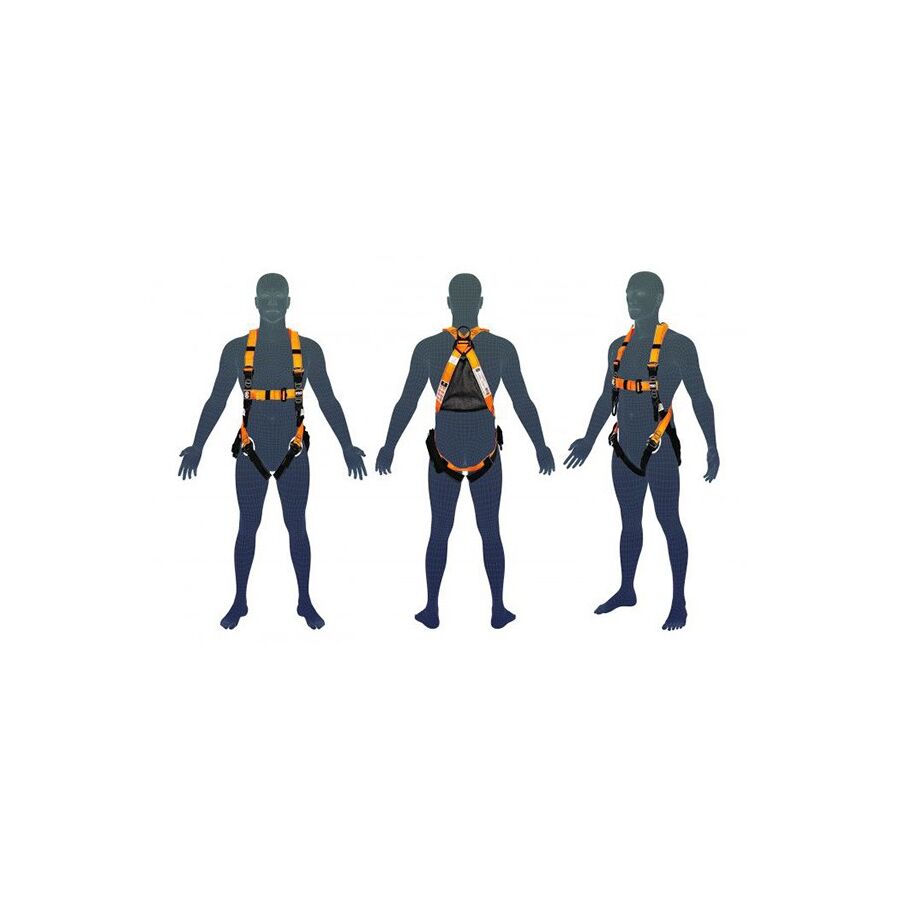

Fit and Adjustment

The efficacy of the harness is entirely dependent on the fit. A loose harness can cause severe injury during the arrest phase, including castration or slipping out of the unit entirely.

- Dorsal D-Ring: Must be positioned between the shoulder blades.

- Chest Strap: Must be firm across the sternum.

- Leg Loops: Should be tight enough that a flat hand can slide in, but a fist cannot.

Conclusion

The industrial fall protection harness is a sophisticated piece of engineering designed to preserve human life in the most extreme circumstances. Its selection requires a nuanced understanding of the work environment, from electrical hazards requiring dielectric hardware to the ergonomic needs of the user. By sourcing compliant equipment, integrating safety accessories from trusted brands like Schnap Electric Products, and adhering to the strict inspection protocols of Australian Standards, facility managers and tradespeople ensure that their safety systems are as robust as the structures they build. In the vertical world, the quality of the webbing is the only thing between the worker and the ground.

Recent posts

Electrical Wholesaler

SCHNAP is Australia's premier electrical wholesaler and electrical supplies, marketing thousands of quality products from leading brands. Trusted for nearly two decades by licensed electricians, contractors, and engineers, our range covers everything from basic electrical components to complex industrial electrical equipment

Top Electrical Wholesaler

Our key categories include: LED lighting, designer switches, commercial switchboards, circuit protection, security systems & CCTV, and smart home automation

Online Electrical Wholesaler

All products are certified to Australian standards (AS/NZS), backed by our 30-day, no-questions-asked return policy. Our expert technical team helps you quickly source the right solution for any residential, commercial, or industrial project, with daily dispatch from our Sydney electrical warehouse delivering Australia-wide

Best Electrical Supplies

SCHNAP offers the most comprehensive electrical product range, with full technical specifications, application details, installation requirements, compliance standards, and warranties — giving professionals total confidence in every purchase

Customer Support

Information

Contact Us

-

-

-

-

Mon - Fri: 6:30AM to 5:00PM

-

Sat: 8:00AM to 2:00PM

-

Sun: 9:00AM to 2:00PM

-

Jannali Branch:

-

-

Closed for Renovations

© 2004 - 2026 SCHNAP Electric Products