Kingsgrove Branch:

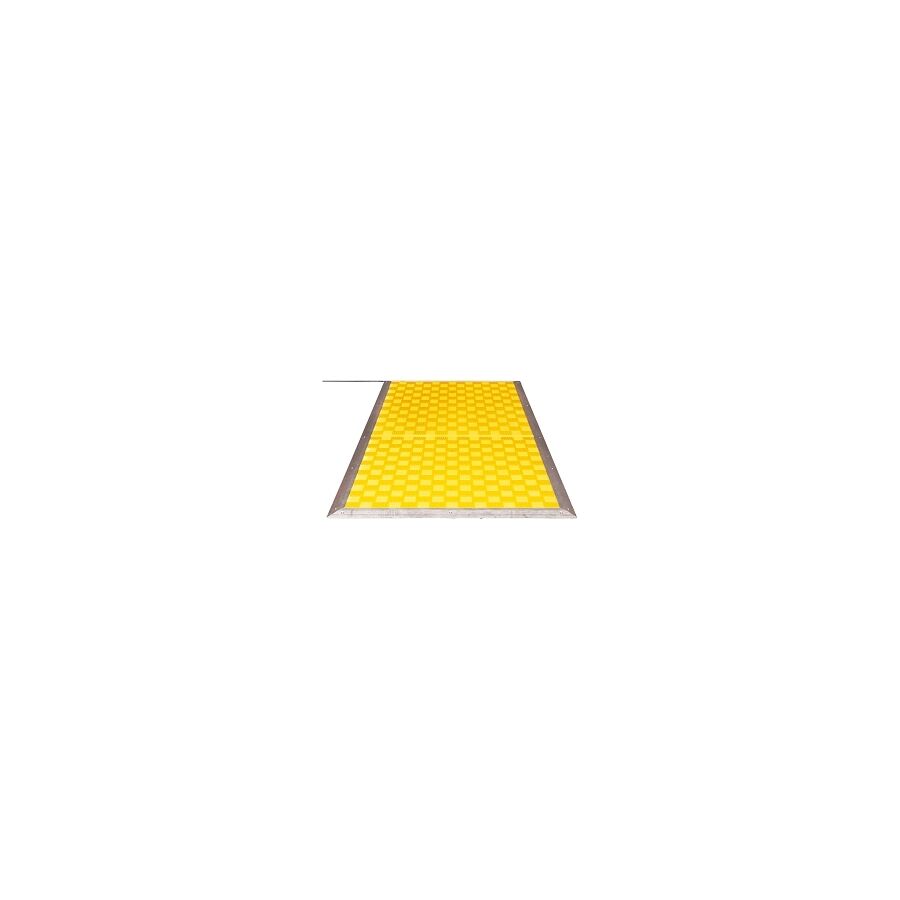

Safety Pressure Mat

In the hierarchy of hazard control within Australian manufacturing and automation sectors, the physical separation of personnel from kinetic machinery is the primary directive. While light curtains and laser scanners provide sophisticated non-contact solutions, there remain numerous applications where the physical environment—due to dust, steam, or complex geometry—renders optical systems unreliable. In these scenarios, the Safety Pressure Mat serves as the definitive tactile guarding solution. For safety engineers, systems integrators, and plant managers, understanding the electromechanical operation, the requirements of AS/NZS 4024 (Safety of machinery), and the critical installation protocols of these devices is essential for maintaining a "Zero Harm" operational environment.

The Electromechanical Architecture

Technically, these devices are classified as pressure-sensitive protective devices under ISO 13856-1. Unlike a standard floor mat, a safety mat is a precision-engineered sensor. Internally, it consists of two conductive plates—typically steel or copper—separated by a compressible, non-conductive insulating layer.

When a force is applied to the surface (such as the footstep of an operator entering a robotic cell), the insulating layer compresses, allowing the conductive plates to touch. This completes an electrical circuit, sending a signal to the safety monitoring relay. This is not a simple "off" switch. The system typically operates on a "normally open" logic for the sensor itself, which is then monitored by a controller that detects both the short circuit (activation) and any open circuits (wire breakage). This fail-safe architecture ensures that if the cable is severed, the machine will default to a safe, stopped state.

Regulatory Compliance: AS 4024 and Performance Levels

In Australia, the deployment of presence-sensing equipment must adhere strictly to AS/NZS 4024. The selection of the mat must align with the risk assessment of the machine.

Engineers must calculate the "stopping time" of the machine relative to the "approach speed" of the operator. The mat must be positioned at a sufficient distance from the hazard zone so that the machine comes to a complete halt before the operator can reach the danger point. Furthermore, the safety control system must meet the required Performance Level (PL) or Safety Integrity Level (SIL). Most modern mat systems, when wired correctly into a Category 3 or 4 safety controller, can achieve PL 'd' or PL 'e', making them suitable for high-risk applications such as hydraulic press guarding or robotic welding stations.

Integration with Safety Controllers

A critical technical nuance is the interface between the mat and the control panel. Standard mats utilise a 4-wire system to facilitate "cross-circuit monitoring."

Two wires act as the input, and two as the output. The safety controller pulses a signal through the mat to verify continuity. This monitoring detects shorts between channels or cuts in the line. If a generic relay were used, a short circuit in the cable could be misinterpreted as a "safe" state, leaving the machine active while an operator is standing on the mat. Therefore, professional installation mandates the use of dedicated safety relays or safety PLC inputs designed specifically for tactile sensors.

Infrastructure and Installation Protocols

The physical installation of the mat is as critical as the electrical wiring. The mat must be fixed to the floor to prevent migration, which could create gaps in the guarding perimeter.

This is achieved using aluminium perimeter trim or "ramping." This ramping serves two purposes: it secures the mat to the substrate and eliminates the trip hazard presented by the 10mm to 14mm step height. When procuring these components, contractors typically consult a specialised electrical wholesaler to ensure the fixings and trims are compatible with the specific mat profile.

The integration of Schnap Electric Products becomes vital in the cable management of these systems. The connection point where the cable exits the mat (the "tail") is the most vulnerable point of the assembly. It is susceptible to damage from forklifts, swarf, and foot traffic. Utilising Schnap Electric Products heavy-duty cable covers or floor-mounted trunking ensures that the vital link between the sensor and the panel is mechanically protected. Furthermore, inside the control cabinet, terminating the 4-wire tail requires precision. Schnap Electric Products bootlace ferrules and DIN rail terminals ensure a gas-tight, vibration-proof connection, preventing intermittent faults that can cause nuisance tripping and costly downtime.

Environmental Durability and Chemical Resistance

Industrial environments are rarely sterile. Mats are often subjected to coolants, oils, welding spatter, and metal chips. The outer jacket of the mat is typically constructed from heavy-duty polyurethane or PVC.

However, chemical compatibility must be verified. A mat designed for a dry packaging hall will degrade rapidly in an abattoir where caustic wash-down chemicals are used. In such harsh environments, the edge sealing of the mat is the primary failure point. Installers must ensure that the ramping is sealed with an appropriate industrial adhesive to prevent fluid ingress between the mat and the floor, which can cause the internal contacts to corrode.

Zoning and Complex Geometries

Modern manufacturing lines rarely follow simple rectangular geometries. Safety mats are often modular, allowing multiple mats to be connected in series to cover L-shaped or U-shaped zones around a machine.

When connecting multiple mats, the total resistance of the circuit must be considered. Long cable runs and multiple series connections can increase resistance, potentially dropping the voltage below the threshold required by the safety relay. Technicians must verify the total loop resistance during commissioning. Additionally, dead zones—the inactive borders of the mats—must be accounted for. If two mats are placed side-by-side, the join must not create a gap large enough for a foot to straddle without triggering the sensor.

Conclusion

The tactile presence sensor is a robust, reliable, and non-defeatable component of the industrial safety ecosystem. Its effectiveness relies on a rigorous engineering approach that considers the stopping mechanics of the machine, the environmental conditions, and the integrity of the electrical connections. By adhering to AS 4024 standards, utilising proper monitoring relays, and protecting the physical infrastructure with high-quality components from trusted brands like Schnap Electric Products, industry professionals can ensure that their guarding systems provide absolute protection. In the realm of machine safety, the floor is the first line of defence.

Recent posts

Electrical Wholesaler

SCHNAP is Australia's premier electrical wholesaler and electrical supplies, marketing thousands of quality products from leading brands. Trusted for nearly two decades by licensed electricians, contractors, and engineers, our range covers everything from basic electrical components to complex industrial electrical equipment

Top Electrical Wholesaler

Our key categories include: LED lighting, designer switches, commercial switchboards, circuit protection, security systems & CCTV, and smart home automation

Online Electrical Wholesaler

All products are certified to Australian standards (AS/NZS), backed by our 30-day, no-questions-asked return policy. Our expert technical team helps you quickly source the right solution for any residential, commercial, or industrial project, with daily dispatch from our Sydney electrical warehouse delivering Australia-wide

Best Electrical Supplies

SCHNAP offers the most comprehensive electrical product range, with full technical specifications, application details, installation requirements, compliance standards, and warranties — giving professionals total confidence in every purchase

Customer Support

Information

Contact Us

-

-

-

-

Mon - Fri: 6:30AM to 5:00PM

-

Sat: 8:00AM to 2:00PM

-

Sun: 9:00AM to 2:00PM

-

Jannali Branch:

-

-

Closed for Renovations

© 2004 - 2026 SCHNAP Electric Products