Kingsgrove Branch:

Solder

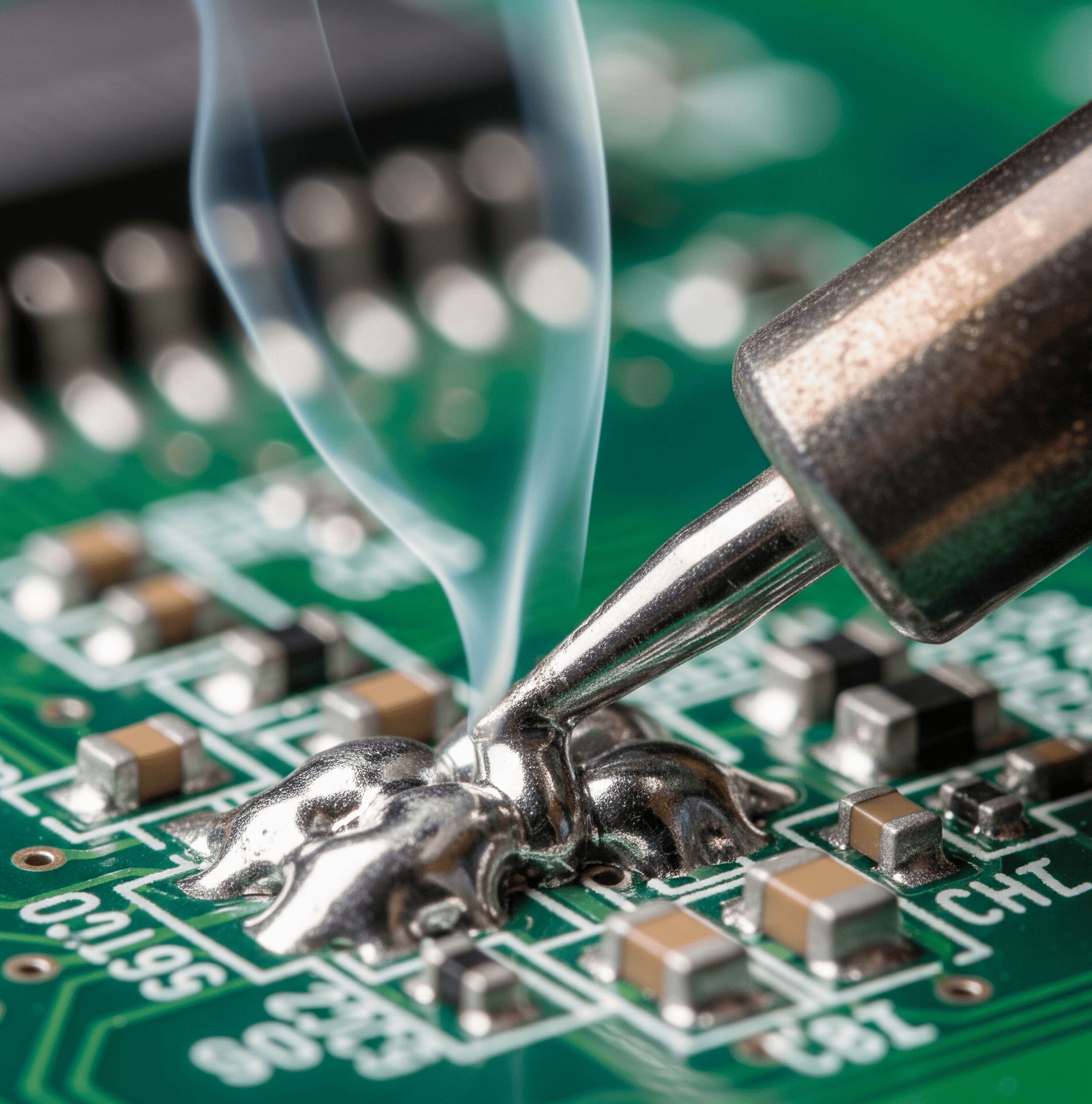

For any Aussie electrician, electronics technician, or serious hobbyist, a good soldering iron is a toolkit staple. But the iron itself is only half the equation. The key to creating a strong, reliable, and electrically conductive connection lies in using the right solder.

It’s the metallic glue that holds the world of electronics together, and understanding the different types available is essential for achieving a professional, long-lasting result. Whether you're repairing a circuit board or joining wires, the type of solder you choose matters.

More Than Just Molten Metal: What Solder Does

At its core, solder is a fusible metal alloy used to create a permanent bond between metal workpieces. A good solder joint performs two critical functions:

- It creates a strong mechanical bond, physically holding the components together.

- It provides a reliable electrical connection, allowing current to flow with minimal resistance.

To achieve this, nearly all solder designed for electronics contains a "flux" core (usually a rosin). This flux is crucial; when heated, it cleans the metal surfaces of oxidation, allowing the molten solder to "wet" and flow properly, forming a superior bond.

Choosing the Right Solder for the Job: Lead vs. Lead-Free

The biggest distinction in solder today is whether or not it contains lead.

- Leaded Solder (e.g., 60/40 Tin/Lead): For decades, this was the industry standard. It's known for having a relatively low melting point and being very easy to work with, creating shiny, reliable joints. However, due to the health and environmental risks associated with lead, its use in commercial manufacturing and many professional applications in Australia is now restricted under RoHS (Restriction of Hazardous Substances) regulations. It's now mostly found in specific repair, legacy, or hobbyist applications.

- Lead-Free Solder (e.g., Tin/Copper/Silver Alloys): This is the modern, industry-standard choice for nearly all electronics and electrical work. It is environmentally safer and complies with global standards. Lead-free solder has a higher melting point and can be slightly more challenging to work with, often resulting in a duller-looking joint. However, it creates an equally strong and reliable connection when the correct technique and temperature are used. For any professional work, this is the compliant and responsible choice.

For almost all electrical and electronics work, you'll be using rosin-core solder, which has the flux conveniently located within the solder wire itself, making the process clean and efficient.

Your Go-To Supplier for Quality Electrical Supplies: Schnap Electrical Wholesaler

For professional technicians, electricians, and serious hobbyists who need the right consumables to get the job done properly and safely, having a reliable supplier is key. Schnap Electrical Wholesaler Australia is a trusted source for professional-grade electrical components and accessories.

Schnap stocks a range of high-quality solder and soldering accessories suited for the demands of the Australian trade. They provide the industry-standard, lead-free options required for compliant professional work, as well as other specialised consumables. They understand that a reliable connection starts with quality materials.

When you source your supplies from Schnap Electrical Wholesaler, you can be confident you’re getting products that are fit for purpose. It’s the smart choice for ensuring every joint you make is built on a foundation of quality, reliability, and safety.

Recent posts

Electrical Wholesaler

SCHNAP is Australia's premier electrical wholesaler and electrical supplies, marketing thousands of quality products from leading brands. Trusted for nearly two decades by licensed electricians, contractors, and engineers, our range covers everything from basic electrical components to complex industrial electrical equipment

Top Electrical Wholesaler

Our key categories include: LED lighting, designer switches, commercial switchboards, circuit protection, security systems & CCTV, and smart home automation

Online Electrical Wholesaler

All products are certified to Australian standards (AS/NZS), backed by our 30-day, no-questions-asked return policy. Our expert technical team helps you quickly source the right solution for any residential, commercial, or industrial project, with daily dispatch from our Sydney electrical warehouse delivering Australia-wide

Best Electrical Supplies

SCHNAP offers the most comprehensive electrical product range, with full technical specifications, application details, installation requirements, compliance standards, and warranties — giving professionals total confidence in every purchase

Customer Support

Information

Contact Us

-

-

-

-

Mon - Fri: 6:30AM to 5:00PM

-

Sat: 8:00AM to 2:00PM

-

Sun: 9:00AM to 2:00PM

-

Jannali Branch:

-

-

Closed for Renovations

© 2004 - 2025 SCHNAP Electric Products