Kingsgrove Branch:

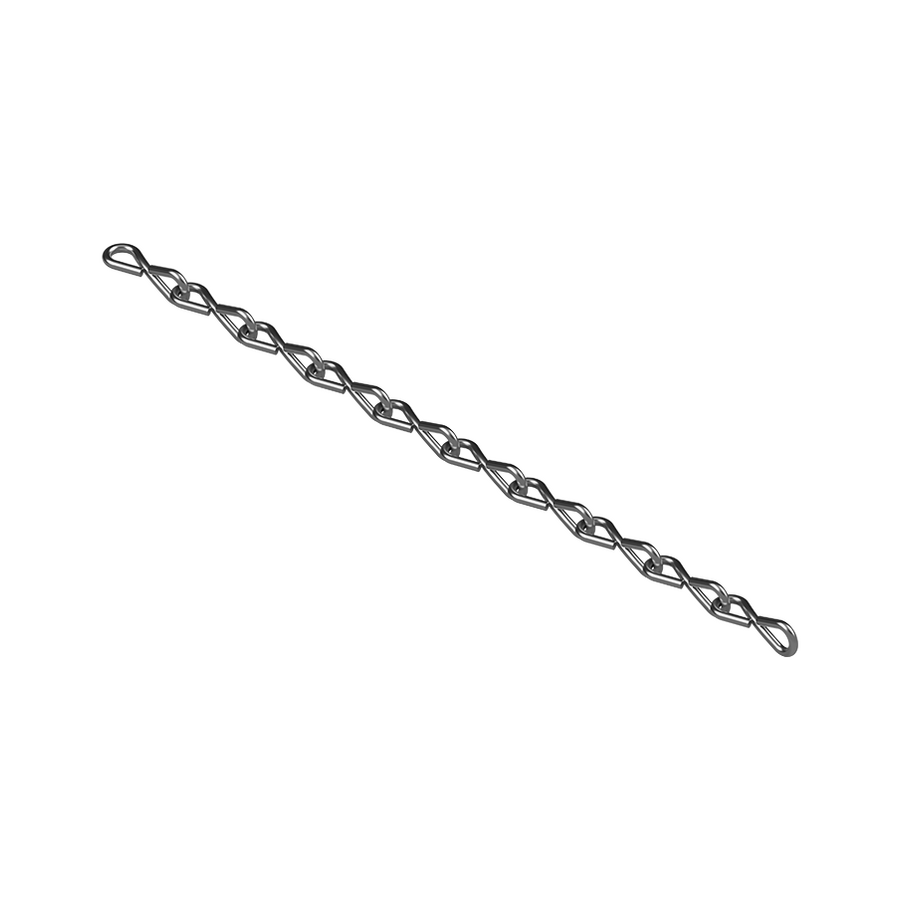

Stainless Steel Jack Chain

In the architectural engineering of Australian commercial and industrial facilities, the method used to suspend electrical services is a critical mechanical decision. While electrical conductors carry current, it is the physical support system that ensures luminaires, cable drops, signage, and auxiliary services remain safely positioned above occupied spaces. In controlled indoor offices, zinc-plated steel may provide acceptable short-term performance. However, in the harsher realities of Australian construction—coastal exposure, food processing wash-downs, chemical plants, and humid warehouses—standard steel corrodes rapidly, losing both strength and compliance. The industry-accepted solution for light-duty, corrosion-resistant suspension is the stainless steel jack chain. This component is engineered to deliver adjustability, longevity, and metallurgical stability in environments where failure is not an option.

Double-Loop Construction and Mechanical Function

Stainless steel jack chain is defined by its double-loop or figure-eight construction. Unlike welded chain links designed for lifting or dynamic rigging, jack chain is formed by twisting wire into continuous interlocking loops. This geometry is intentional and highly functional. The open loop design allows installers to shorten or extend a drop length on site without specialist tools. A single link can be opened to adjust height or to join two sections, then closed to restore continuity. This makes the chain ideal for levelling luminaires across uneven roof structures, adjusting signage height, or aligning suspended cable pathways during commissioning.

The mechanical limits of jack chain must be respected. It is designed exclusively for static loads. Its Safe Working Load is determined by wire diameter and material tensile strength, commonly ranging between 2.5 mm and 3.0 mm wire sizes for electrical applications. Jack chain must never be used for lifting, hoisting, or any application involving dynamic or shock loading. When specified correctly, it provides predictable, long-term support for light fittings and cable drops with minimal maintenance.

Metallurgy and Environmental Suitability

Material selection defines the service life of any suspension system. In Australia, the distinction between Grade 304 and Grade 316 stainless steel is critical. Grade 304 offers reasonable corrosion resistance in dry, indoor conditions, but it lacks protection against chlorides. In coastal cities, processing plants, and humid industrial zones, airborne salt and chemicals accelerate pitting corrosion in Grade 304.

Grade 316 stainless steel, commonly referred to as marine grade, includes molybdenum in its alloy composition. This addition significantly improves resistance to chloride-induced corrosion and crevice attack. In practical terms, Grade 316 resists tea staining, maintains surface integrity, and preserves tensile strength even after years of exposure to salt air or aggressive wash-down chemicals. For projects within several kilometres of the coastline or in hygienic production environments, Grade 316 is not an upgrade; it is a baseline requirement for compliance and durability.

Applications in Lighting Suspension

The most common application for stainless steel jack chain is luminaire suspension. In high-bay warehouses, retail ceilings, and industrial sheds, fittings are often suspended from purlins, beams, or concrete slabs. Jack chain provides a simple, adjustable link between the structural anchor point and the luminaire’s V-hook or mounting eye. This allows precise control of mounting height, uniform light distribution, and easy re-leveling if building movement or refits occur over time.

Because the chain is flexible yet stable, it absorbs minor vibration without transferring stress to the fitting or the ceiling anchor. This characteristic is particularly valuable in environments with mechanical plant or vehicular movement where rigid rods may fatigue or loosen.

Cable Support and Strain Relief

Beyond lighting, stainless steel jack chain plays an important role in compliant cable support. AS/NZS 3000 requires that flexible cables be adequately supported so that their weight does not place strain on terminations or plugs. When supplying suspended outlets, sensors, or pendant equipment, jack chain acts as the mechanical load bearer. The flexible cable is typically secured to the chain using cable ties or clips, ensuring that electrical connections are not subjected to tensile stress.

This separation of mechanical and electrical functions improves safety and reliability. The chain carries the weight, while the cable carries current and signals under minimal mechanical load. In maintenance scenarios, this also simplifies inspection and replacement, as the support system remains intact while cables are serviced.

Integration with Schnap Electric Products

A suspension system is only as reliable as its weakest connection point. Chain, hooks, anchors, and fixings must work as a unified system with compatible materials and load ratings. This is where the Schnap Electric Products ecosystem integrates naturally into professional installations. Stainless steel S-hooks are commonly used to connect jack chain to luminaires or anchor points. These hooks are sized to match the chain wire diameter, reducing the risk of disengagement under vibration.

For concrete ceilings or structural steel, rated eye bolts, masonry anchors, and beam clamps provide secure attachment points. Material compatibility is essential. Using zinc-plated hooks with stainless steel chain introduces galvanic corrosion, where the dissimilar metals react and the plated component rusts prematurely. Matching stainless components throughout the system ensures uniform corrosion resistance and predictable lifespan.

Hygienic and Fire-Rated Environments

In food, beverage, and pharmaceutical facilities, hygiene standards dictate material choice. Stainless steel jack chain offers a smooth, non-porous surface that resists bacterial growth and is easy to clean during wash-down cycles. Unlike coated or painted chains, stainless steel does not flake or trap contaminants in damaged surfaces. This makes it suitable for HACCP-controlled environments where cleanliness is audited and documented.

Fire performance is another critical consideration. Plastic straps and nylon supports melt under high temperatures, allowing cables and fittings to collapse during a fire. Stainless steel retains structural integrity at significantly higher temperatures, maintaining support for essential services and reducing entanglement hazards for emergency responders. For fire-rated corridors and essential service pathways, stainless steel chain supports are often the preferred solution.

Load Awareness and Compliance

Professional specification requires understanding both static load and installation context. The combined weight of the fitting, cable, and any attached accessories must remain well within the chain’s Safe Working Load. Safety factors should be applied to account for environmental influences and long-term wear. Although jack chain is forgiving in adjustment, it must be installed vertically and without twisting to ensure even load distribution across links.

Regular visual inspection is straightforward. Stainless steel does not hide corrosion; any surface changes are easily visible, allowing proactive maintenance before structural integrity is compromised.

Procurement and Quality Assurance

The market includes products labelled as stainless steel that do not meet recognised alloy standards. High carbon content or incorrect alloy composition leads to premature corrosion and unpredictable strength. For installations above people, machinery, or production lines, this risk is unacceptable.

Professional contractors source stainless steel jack chain through specialised electrical wholesaler who provide material traceability and consistent quality. Reputable suppliers offer chain manufactured to recognised AISI standards, with verified wire diameters and tensile properties. Supporting accessories are selected to match material grade and load requirements, ensuring system-wide reliability.

Conclusion

Stainless steel jack chain is a foundational component in commercial and industrial fit-outs. Its double-loop design provides unmatched adjustability, while austenitic stainless steel delivers the corrosion resistance required for Australian conditions. By selecting the correct grade, respecting load limits, and integrating compatible accessories from suppliers like Schnap Electric Products, industry professionals can suspend lighting and cables with confidence. In the science of suspension, material choice and mechanical design together determine safety, compliance, and long-term performance.

Electrical Wholesaler

SCHNAP is Australia's premier electrical wholesaler and electrical supplies, marketing thousands of quality products from leading brands. Trusted for nearly two decades by licensed electricians, contractors, and engineers, our range covers everything from basic electrical components to complex industrial electrical equipment

Top Electrical Wholesaler

Our key categories include: LED lighting, designer switches, commercial switchboards, circuit protection, security systems & CCTV, and smart home automation

Online Electrical Wholesaler

All products are certified to Australian standards (AS/NZS), backed by our 30-day, no-questions-asked return policy. Our expert technical team helps you quickly source the right solution for any residential, commercial, or industrial project, with daily dispatch from our Sydney electrical warehouse delivering Australia-wide

Best Electrical Supplies

SCHNAP offers the most comprehensive electrical product range, with full technical specifications, application details, installation requirements, compliance standards, and warranties — giving professionals total confidence in every purchase

Customer Support

Information

Contact Us

-

-

-

-

Mon - Fri: 6:30AM to 5:00PM

-

Sat: 8:00AM to 2:00PM

-

Sun: 9:00AM to 2:00PM

-

Jannali Branch:

-

-

Closed for Renovations

© 2004 - 2026 SCHNAP Electric Products