Kingsgrove Branch:

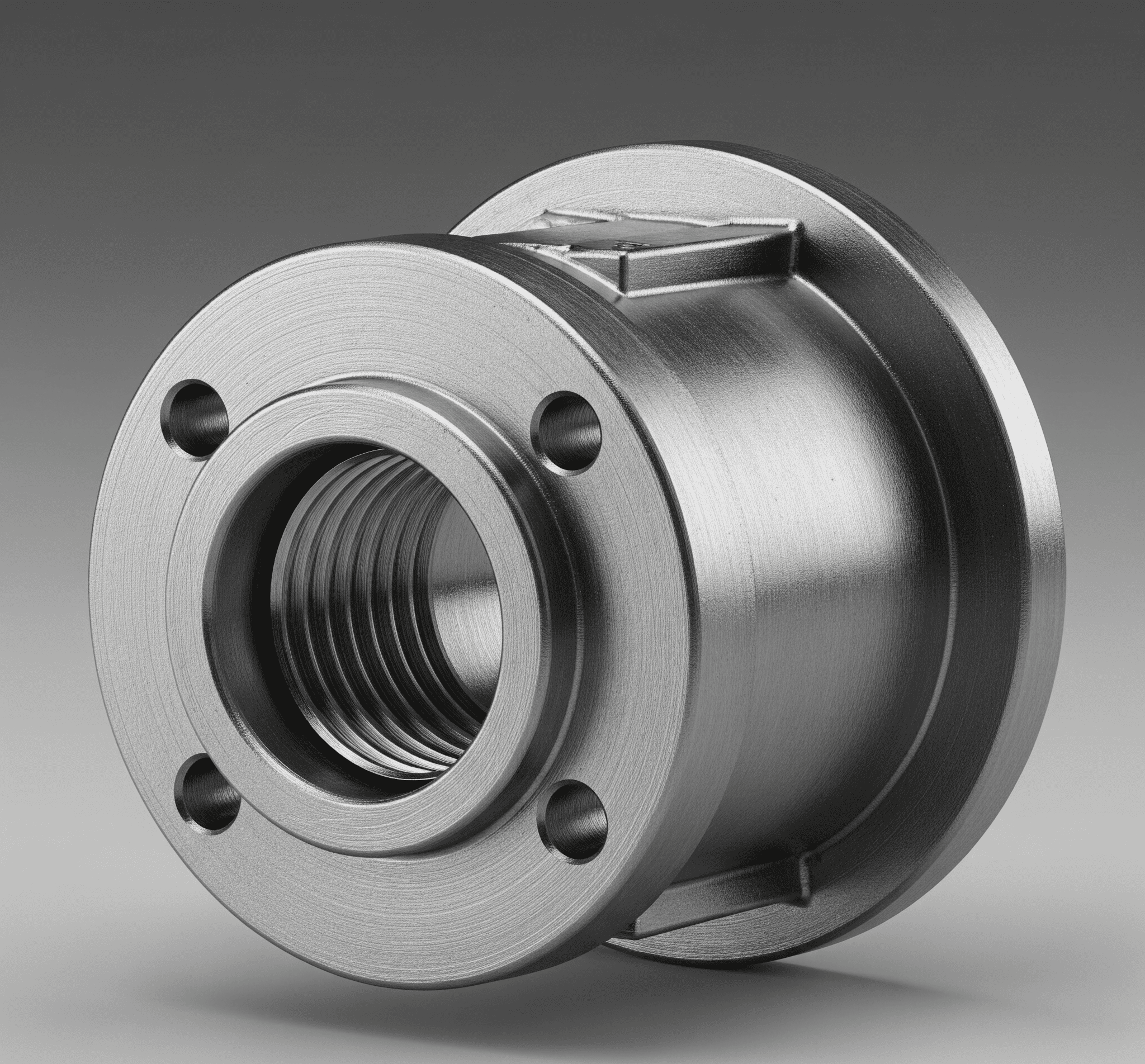

Steel Bush

Steel bush: From basic bearings to complex machinery, understanding these crucial components is key. This deep dive explores their design, materials, applications, and maintenance, equipping you with the knowledge to select and use them effectively. Imagine a world without smooth, reliable machinery; steel bushes are the unsung heroes making it all possible

This guide provides a comprehensive overview of steel bushes, from their fundamental properties to their sophisticated applications in various industries. We'll delve into their manufacturing processes, examining the critical steps involved in producing these vital components. Understanding the factors that influence their performance, reliability, and lifespan is also essential, and we will explore these elements in detail

Introduction to Steel Bushings

Steel bushings are essential components in various mechanical systems. They act as bearings, providing a smooth and reliable interface between rotating shafts and their housings. Understanding their characteristics, applications, and manufacturing processes is key to selecting the right bushing for a specific task

Definition of a Steel Bush

A steel bushing is a cylindrical sleeve made from steel, designed to fit over a shaft and into a housing. It reduces friction and wear, allowing for smooth rotation and minimizing stress on the shaft and housing components

Materials Used in Manufacturing

Various steel grades are used, each offering different properties like hardness, strength, and corrosion resistance. Common materials include carbon steel, alloy steel, and stainless steel, depending on the intended application and operating conditions

Types of Steel Bushings

Steel bushings are categorized based on their intended use. This categorization often considers load capacity and operating environment. Examples include:

- Light-duty: Suitable for applications with low loads and speeds, often used in less demanding machinery

- Heavy-duty: Designed to withstand significant loads and high speeds, commonly used in industrial equipment

- High-speed: Optimized for applications involving rapid rotation, minimizing friction and wear at high speeds

- Corrosion-resistant: Made from stainless steel or other corrosion-resistant alloys, suitable for environments with moisture or chemicals

Sizes and Dimensions

| Outer Diameter (mm) | Length (mm) |

|---|---|

| 12 | 25 |

| 22 | 50 |

| 32 | 75 |

Properties and Characteristics Comparison

| Carbon Steel | Stainless Steel |

|---|---|

| Medium | Medium-High |

| Moderate | Moderate |

| Low | High |

Applications of Steel Bushings

Steel bushings find widespread use across various industries. Their ability to reduce friction and support rotating shafts makes them indispensable in many mechanical systems

Diverse Applications

Steel bushings are crucial components in a wide range of industries, including:

- Automotive: Used in various engine components and transmission systems

- Machinery: Found in gears, bearings, and other rotating components

- Agriculture: Employed in agricultural machinery for efficient operation

- Construction: Supporting rotating elements in construction equipment

Manufacturing Processes

The manufacturing process of steel bushings significantly impacts their quality and performance. Precision is critical

Methods Used

Common methods for producing steel bushings include machining, casting, and forging. Each method has specific advantages and limitations

Quality Control, Steel bush

Rigorous quality control measures are implemented throughout the manufacturing process to ensure consistent quality and dimensional accuracy

Conclusion

In conclusion, steel bushes are more than just simple components; they are the silent engines of efficiency in countless applications. Their diverse properties, meticulous manufacturing, and careful selection procedures ensure their longevity and effectiveness. This guide has provided a detailed look into the fascinating world of steel bushes, from their inception to their impact on various industries. We hope this information proves invaluable in your endeavors

FAQ Overview: Steel Bush

What are the most common materials used in steel bush manufacturing?

Common materials include various grades of steel, often chosen for their strength, hardness, and wear resistance. Specific choices depend on the application's demands. See heavy duty

How do I determine the right size of steel bush for my application?

Refer to the provided tables for size and dimension information, considering the shaft diameter and the load capacity needed

What are the potential maintenance issues with steel bushes?

Common issues include wear, corrosion, and lubrication problems. Regular inspection and proper maintenance are crucial

What are some alternatives to steel bushes?

Alternative materials, like plastics or composites, might be suitable depending on the application's specific requirements. Cost-effectiveness and environmental factors also play a role in material selection

Recent posts

Electrical Wholesaler

SCHNAP is Australia's premier electrical wholesaler and electrical supplies, marketing thousands of quality products from leading brands. Trusted for nearly two decades by licensed electricians, contractors, and engineers, our range covers everything from basic electrical components to complex industrial electrical equipment

Top Electrical Wholesaler

Our key categories include: LED lighting, designer switches, commercial switchboards, circuit protection, security systems & CCTV, and smart home automation

Online Electrical Wholesaler

All products are certified to Australian standards (AS/NZS), backed by our 30-day, no-questions-asked return policy. Our expert technical team helps you quickly source the right solution for any residential, commercial, or industrial project, with daily dispatch from our Sydney electrical warehouse delivering Australia-wide

Best Electrical Supplies

SCHNAP offers the most comprehensive electrical product range, with full technical specifications, application details, installation requirements, compliance standards, and warranties — giving professionals total confidence in every purchase

Customer Support

Information

Contact Us

-

-

-

-

Mon - Fri: 6:30AM to 5:00PM

-

Sat: 8:00AM to 2:00PM

-

Sun: 9:00AM to 2:00PM

-

Jannali Branch:

-

-

Closed for Renovations

© 2004 - 2026 SCHNAP Electric Products