Kingsgrove Branch:

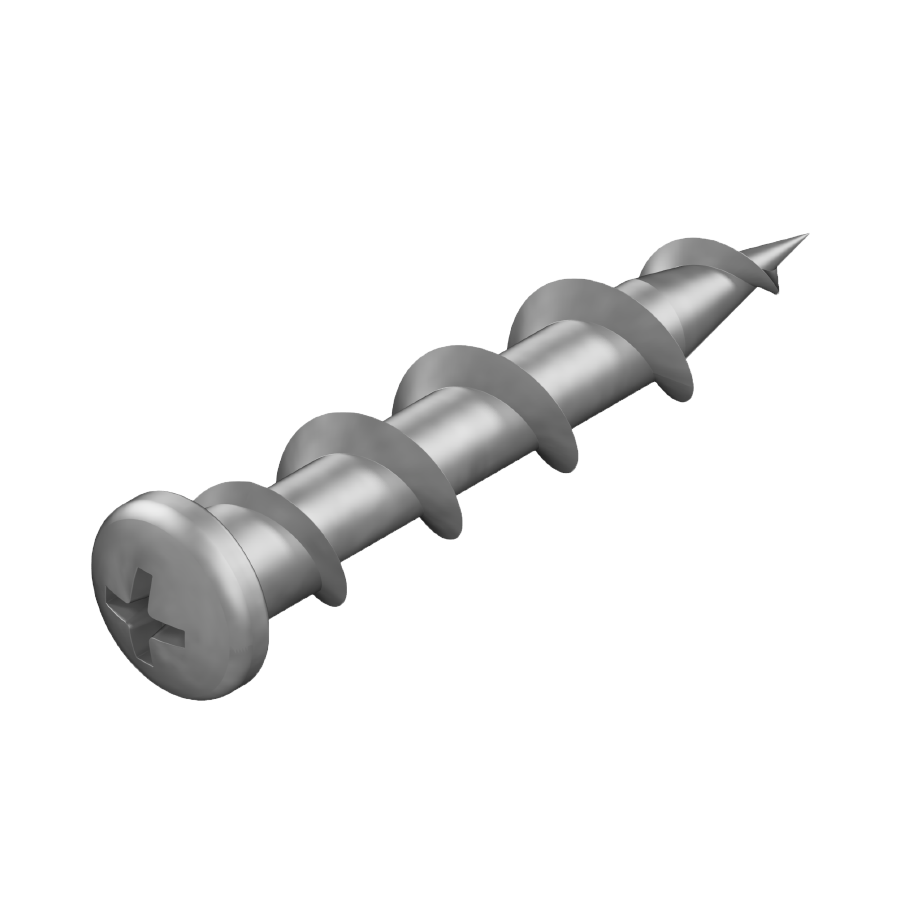

Wall Lock Needle Point Screws

In the fast-paced environment of the Australian construction sector, productivity during the rough-in and fit-off stages directly influences project margins. For electricians, data technicians, and security installers, few tasks are repeated more often than fixing accessories to walls and framing. Mounting blocks, conduit clips, data plates, isolators, and control devices must be secured quickly, accurately, and with confidence that they will remain firmly fixed for the life of the installation. While traditional wall plugs, anchors, and adhesives still have their place, the industry standard for rapid, high-retention fixing into soft substrates is the wall lock needle point screw.

These fasteners are purpose-engineered for plasterboard, fibre cement, and timber. They are not generic wood screws. Their geometry, thread profile, and surface treatment are designed to deliver immediate bite, high pull-out resistance, and clean finishes without pilot drilling. In high-volume residential builds and commercial fit-outs, this translates into measurable time savings, reduced rework, and consistent mechanical performance across hundreds of fixing points.

Needle Point Geometry and Material Displacement

The defining feature of this fastener is the needle point. Unlike self-drilling or Tek screws that remove material to create a hole, the needle point is designed to pierce and displace the substrate. This distinction is critical in plasterboard and timber.

Plasterboard derives much of its strength from the compressed gypsum core and the integrity of the paper face. When a drill point removes this material, the threads have less substance to engage with, reducing holding power. A needle point, by contrast, separates fibres and compresses the surrounding material as it advances. This compression increases friction and mechanical interlock, producing higher pull-out resistance and improved long-term stability.

The sharpness of the point also enables instant grab. On ceilings or awkward wall positions, the screw engages immediately under light pressure. This prevents skating across painted surfaces and eliminates the need to pre-position the screw with two hands, a small but meaningful efficiency gain repeated dozens of times per day.

Twin-Thread Architecture and Installation Speed

Speed is a critical metric on any construction site. Wall lock needle point screws often incorporate a twin-thread or double-lead design. Two parallel threads wrap around the shank, effectively doubling the pitch.

This means the screw advances further with each rotation of the driver, reducing drive time by up to 50 percent compared to single-thread fasteners. For trades installing hundreds of conduit saddles or mounting clips, the cumulative time saving is substantial. Reduced drive time also means less heat buildup in the screw and driver bit, lowering the risk of head stripping and extending tool life.

The thread profile itself is typically aggressive, with deep, sharp flanks that maximise contact area in crumbly gypsum cores and soft timbers. This geometry is optimised for pull-out strength rather than tensile load, aligning with the real-world forces acting on wall-mounted electrical accessories.

Head Design and Torque Control

The screw head is the interface between tool and fastener, and poor design here leads to cam-out, stripped heads, and damaged wall finishes. Professional wall lock screws are manufactured with drive recesses that support high torque without slippage.

Phillips #2 remains common, but square drive (Robertson) heads are increasingly preferred for their superior torque transfer and stick-fit capability. The square recess allows the screw to stay on the driver bit without magnets, an advantage when working overhead or in confined spaces.

Head shape is equally important. Bugle heads are designed to sit flush with plasterboard, spreading load evenly and preventing the paper face from tearing. Pan heads and button heads provide a flat bearing surface ideal for plastic accessories, reducing the risk of cracking conduit clips or mounting blocks under compression.

Compatibility with Electrical Accessories

In electrical installations, fasteners are rarely standalone items. They form part of a system that includes mounting blocks, enclosures, and surface accessories. The gauge and head diameter of wall lock needle point screws are selected to match the moulded fixing points of common electrical hardware.

This is where integration with the Schnap Electric Products ecosystem becomes relevant. Their mounting blocks, surface accessories, and weatherproof devices are designed with fixing apertures that align with standard 6g and 7g needle point screws. This compatibility ensures the screw passes cleanly through the accessory without splitting the plastic boss, then engages the substrate with full thread depth. For heavier devices such as isolators or weatherproof fittings, the aggressive needle point enables secure fixing into timber noggins or framing members behind wall linings, supporting compliance with AS/NZS 3000 mechanical strength requirements.

Corrosion Resistance and Coating Systems

Although many installations are internal, corrosion resistance cannot be ignored. Australian humidity, coastal air, and moisture-prone locations such as laundries and bathrooms accelerate corrosion in unprotected fasteners.

Professional wall lock screws are typically finished with zinc-based coatings, most commonly yellow zinc or gold passivation. This electroplated layer provides sacrificial protection, preventing oxidation of the steel core and maintaining a clean appearance over time. A properly applied coating also reduces friction during driving, improving installation consistency.

For semi-external or sheltered outdoor applications, heavier galvanised coatings are specified. These provide increased coating thickness and durability, resisting corrosion where occasional moisture exposure is expected. Selecting the correct coating class ensures that rust does not bleed through paint finishes or compromise fixing strength years after installation.

Substrate Performance and Load Behaviour

Wall lock needle point screws are optimised for soft substrates, but understanding their limitations is part of professional practice. In plasterboard, they provide excellent resistance to shear loads generated by switches, sockets, and clips. However, for heavy cantilevered loads, additional anchors or fixings into framing may still be required.

In timber studs and noggins, the needle point excels. The displaced fibres compress around the thread, creating a tight mechanical lock that resists vibration and repeated load cycles. This behaviour makes these screws particularly suitable for accessories subject to frequent operation, such as light switches and control panels.

Procurement and Quality Assurance

Not all needle point screws perform equally. The market includes low-grade fasteners manufactured from soft steel with inconsistent point geometry and thin coatings. These screws may snap under torque, strip easily, or fail prematurely due to corrosion.

Professional contractors source fasteners through specialised electrical wholesaler who provide consistency and traceability. Quality screws are batch-tested for torsional strength, shear resistance, and coating thickness. This quality assurance reduces on-site failures and eliminates the costly rework associated with broken or stripped fasteners embedded in finished walls.

Conclusion

Wall lock needle point screws are a small component with a large impact on installation quality and efficiency. Their sharp point geometry, twin-thread design, and controlled head profiles deliver fast, secure fixing in plasterboard and timber without pilot drilling. When combined with appropriate corrosion protection and matched to compatible accessories, they provide a reliable foundation for electrical fit-outs across residential and commercial projects. By selecting professional-grade fasteners and integrating them with quality systems from suppliers like Schnap Electric Products, Australian trades can achieve faster installs, cleaner finishes, and long-term mechanical reliability. In the science of fixing, precision at the point makes all the difference.

Electrical Wholesaler

SCHNAP is Australia's premier electrical wholesaler and electrical supplies, marketing thousands of quality products from leading brands. Trusted for nearly two decades by licensed electricians, contractors, and engineers, our range covers everything from basic electrical components to complex industrial electrical equipment

Top Electrical Wholesaler

Our key categories include: LED lighting, designer switches, commercial switchboards, circuit protection, security systems & CCTV, and smart home automation

Online Electrical Wholesaler

All products are certified to Australian standards (AS/NZS), backed by our 30-day, no-questions-asked return policy. Our expert technical team helps you quickly source the right solution for any residential, commercial, or industrial project, with daily dispatch from our Sydney electrical warehouse delivering Australia-wide

Best Electrical Supplies

SCHNAP offers the most comprehensive electrical product range, with full technical specifications, application details, installation requirements, compliance standards, and warranties — giving professionals total confidence in every purchase

Customer Support

Information

Contact Us

-

-

-

-

Mon - Fri: 6:30AM to 5:00PM

-

Sat: 8:00AM to 2:00PM

-

Sun: 9:00AM to 2:00PM

-

Jannali Branch:

-

-

Closed for Renovations

© 2004 - 2026 SCHNAP Electric Products