Kingsgrove Branch:

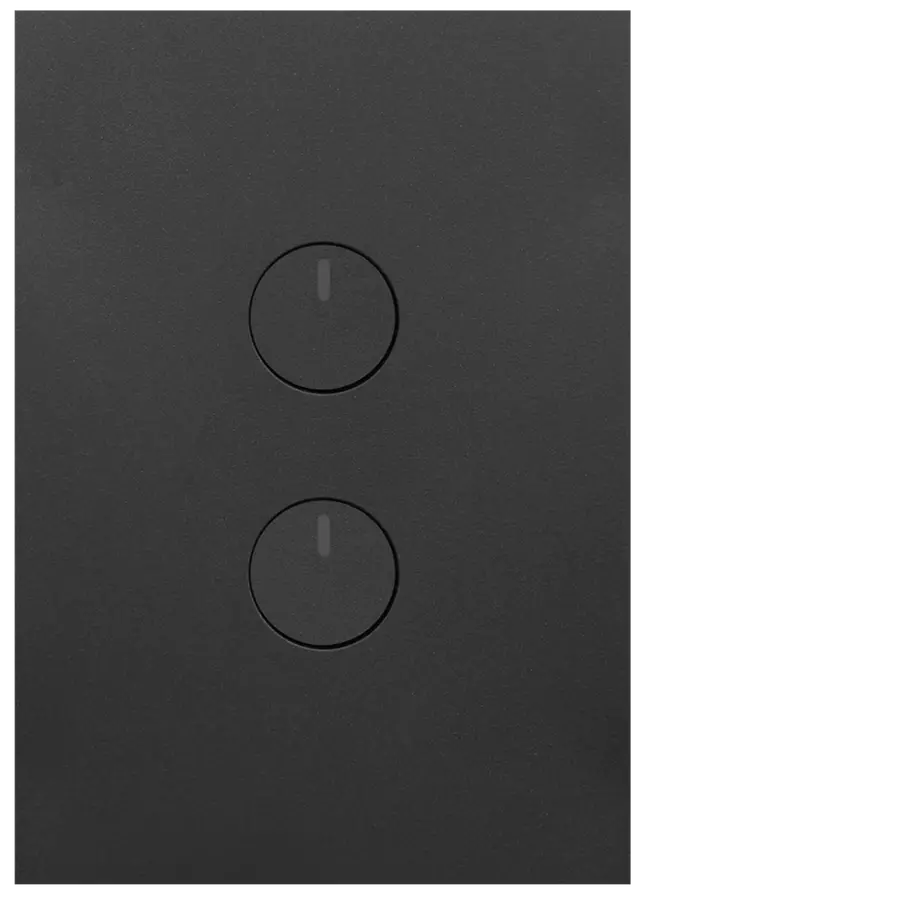

2 Gang Switch

In contemporary Australian homes and light-commercial spaces, electrical design has moved well beyond the era of a single light controlled by a single switch. Open-plan layouts, layered lighting schemes, ceiling fans with integrated light kits, and outdoor feature lighting all demand more nuanced control. A single gang switch often falls short in these scenarios, forcing designers to add extra wall plates that clutter finishes and disrupt architectural flow. The industry standard solution for managing two independent electrical loads from one wall position is the 2 gang switch. By integrating two discrete switch mechanisms into a single plate footprint, this device delivers functional density without sacrificing ergonomics or compliance, making it one of the most widely specified switching formats in Australian construction.

The Modular Grid and Plate System

The defining advantage of Australian switching hardware lies in the grid and plate architecture. A 2 gang switch is not a fixed unit but a configurable assembly composed of a mounting grid, two independent switch mechanisms, and a fascia plate. This modularity provides exceptional flexibility during both initial installation and future upgrades.

Using the Schnap Electric Products modular system, a 2 gang grid can house any compatible combination of mechanisms. Typical residential configurations include two 10 amp lighting switches, but the same grid can support a dimmer paired with a standard switch, a fan controller next to a light switch, or a momentary mechanism for automation alongside a mechanical isolator. This adaptability allows electricians to tailor the control interface precisely to the function of the space without enlarging wall penetrations or altering the visual language of the fit-out.

Wiring Density and Box Fill Considerations

Although the external footprint of a 2 gang switch is identical to a single gang plate, the internal wiring complexity is significantly higher. Two active feeds, two switched actives, earth conductors, and often looping neutrals must all be accommodated within a standard mounting block.

AS/NZS 3000 places clear responsibility on the installer to ensure that insulation is not damaged by overcrowding and that conductors are not subjected to mechanical stress. Effective cable dressing is essential. Outer sheaths should be stripped back only to the cable entry point, conductors should be folded neatly rather than compressed, and excess copper should never be forced behind the mechanisms. High-quality switch mechanisms incorporate dedicated looping terminals that allow the active feed to be bridged cleanly between both switches without creating bulky wire joints. This disciplined approach reduces resistance, minimises heat build-up, and ensures the plate can be refitted flush to the wall.

Two-Way Switching Applications

One of the most common technical reasons for specifying a 2 gang switch is two-way switching. Hallways, staircases, and large living spaces often require a lighting circuit to be controlled from two locations. In these scenarios, one gang of the switch is dedicated to the two-way circuit, while the second gang may control an unrelated load such as an external light or exhaust fan.

Correct termination of the common and strapper conductors is critical. Professional mechanisms clearly identify common and traveller terminals, reducing the risk of mis-wiring. Poorly marked or generic mechanisms increase the likelihood of cross-connection, which can result in short circuits or non-functional switching. In a compliant installation, each mechanism operates independently, even when housed within the same grid, preserving both safety and functionality.

LED Loads and Inrush Behaviour

The widespread adoption of LED lighting has fundamentally altered the electrical stresses experienced by switching hardware. LED drivers are highly capacitive and can draw extremely high inrush currents at the moment of switch-on. When a 2 gang switch controls two LED circuits simultaneously, the cumulative surge can be substantial.

Switch mechanisms must therefore be rated for inductive or electronic loads rather than purely resistive ones. Mechanisms with silver-nickel contacts, strong spring pressure, and rapid break action are essential to prevent contact welding. Specifying LED-compatible mechanisms is particularly important in kitchens, garages, and workshops where higher wattage LED fittings are common. Failure to consider inrush behaviour is one of the leading causes of premature switch failure in modern installations.

Orientation and Ergonomic Layout

A 2 gang switch may be mounted vertically or horizontally depending on architectural intent. Vertical orientation is common near doorways, while horizontal mounting is frequently used above kitchen splashbacks or bathroom vanities to align with tile layouts and joinery lines.

Professional systems allow the switch mechanisms to be rotated within the grid so that rocker orientation remains intuitive. Regardless of plate orientation, the user expects consistent tactile logic. Ensuring that the switches operate in the conventional direction avoids confusion and improves the overall user experience. This level of detail is often overlooked in low-cost products but is a hallmark of professional electrical design.

Materials and Durability

With two mechanisms housed closely together, the fascia plate of a 2 gang switch has thinner structural sections than a single gang plate. Inferior plastics can flex, crack, or discolour over time, particularly in sunlit Australian interiors.

High-quality plates are manufactured from UV-stabilised polycarbonate or ASA, materials chosen for their impact resistance and long-term colour stability. These materials ensure that the switch remains visually consistent with surrounding finishes while maintaining adequate protection against dust and incidental moisture. Durability at this level is not just cosmetic; cracked or degraded plates compromise electrical safety and must be replaced.

Compliance and Certification

Every 2 gang switch installed in Australia must carry the Regulatory Compliance Mark and meet the requirements of AS/NZS 3133 and AS/NZS 3000. Non-compliant products are illegal to install and expose contractors and property owners to liability.

Compliance extends beyond the switch itself. Mounting blocks, grids, and accessories must also meet fire and insulation standards. Sourcing complete systems from reputable electrical wholesaler ensures that all components are compatible and certified for Australian conditions.

Procurement and System Reliability

The electrical accessory market contains a wide range of products with varying levels of quality and compliance. Specialist electrical wholesalers act as critical quality filters, supplying switchgear that has been tested for endurance, thermal performance, and mechanical integrity.

These suppliers also provide guidance on derating requirements when mechanisms are installed side by side, particularly where dimmers or electronic controllers are involved. Access to proper technical data ensures that the final installation performs reliably over its full service life.

Conclusion

The 2 gang switch is the cornerstone of functional lighting control in Australian homes and commercial spaces. It delivers flexibility, reduces wall clutter, and supports modern zoning concepts when specified and installed correctly. By understanding wiring density, two-way switching logic, LED inrush behaviour, and the importance of modular grid systems, and by using proven hardware from manufacturers such as Schnap Electric Products, industry professionals can achieve installations that are safe, compliant, and intuitive to use. In electrical design, effective control begins with thoughtful consolidation.

Recent posts

Electrical Wholesaler

SCHNAP is Australia's premier electrical wholesaler and electrical supplies, marketing thousands of quality products from leading brands. Trusted for nearly two decades by licensed electricians, contractors, and engineers, our range covers everything from basic electrical components to complex industrial electrical equipment

Top Electrical Wholesaler

Our key categories include: LED lighting, designer switches, commercial switchboards, circuit protection, security systems & CCTV, and smart home automation

Online Electrical Wholesaler

All products are certified to Australian standards (AS/NZS), backed by our 30-day, no-questions-asked return policy. Our expert technical team helps you quickly source the right solution for any residential, commercial, or industrial project, with daily dispatch from our Sydney electrical warehouse delivering Australia-wide

Best Electrical Supplies

SCHNAP offers the most comprehensive electrical product range, with full technical specifications, application details, installation requirements, compliance standards, and warranties — giving professionals total confidence in every purchase

Customer Support

Information

Contact Us

-

-

-

-

Mon - Fri: 6:30AM to 5:00PM

-

Sat: 8:00AM to 2:00PM

-

Sun: 9:00AM to 2:00PM

-

Jannali Branch:

-

-

Closed for Renovations

© 2004 - 2026 SCHNAP Electric Products