Kingsgrove Branch:

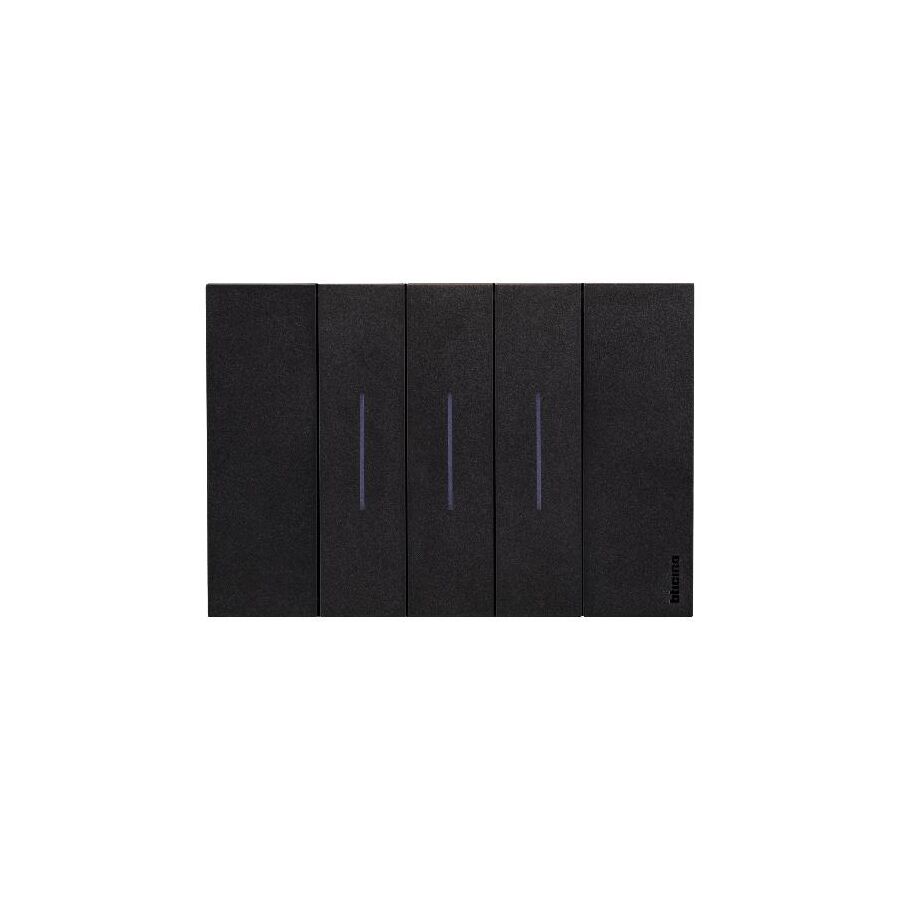

3 Gang Switch

In contemporary Australian residential and commercial interiors, lighting is no longer a single, central utility. It is a layered design element that shapes how spaces are used and experienced. Living rooms combine general downlighting with pendants and feature wall lighting. Kitchens separate task lighting from ambient and island illumination. Offices divide presentation zones from circulation and work areas. This zoning approach demands multiple independently controlled circuits, yet architects and clients increasingly expect clean wall lines with minimal visual clutter. The industry standard solution that balances these competing requirements is the 3 gang switch. By consolidating control of three independent electrical loads into a single wall plate, it delivers functional density while preserving aesthetics, provided the installation respects the physical and electrical limits of the system.

The Modular Grid and Plate Architecture

The Australian 3 gang switch is defined by its modular grid and plate construction. Rather than being a single moulded unit, it is assembled from three core components: the mounting grid, the individual switch mechanisms, and the fascia plate. This architecture offers flexibility that is essential in modern fit-outs.

A 3 gang plate does not need to contain three identical switches. It can house a combination of one-way, two-way, intermediate, or dimmer mechanisms depending on circuit logic. This is particularly valuable in open-plan areas where one switch may control a two-way hallway circuit, another a pendant light, and the third an outdoor zone. The rigidity of the grid is critical. With three mechanisms installed side by side, the grid must resist twisting when fixed to uneven plasterboard or rendered masonry. Systems supplied by Schnap Electric Products are engineered with reinforced screw points and stable polymers that maintain alignment, ensuring the fascia clips on cleanly and remains flush over time.

Wiring Density and Box Fill Management

The most significant technical challenge with a 3 gang switch is wiring congestion. Three actives, three switched actives, earth conductors, and often looping neutrals must all be accommodated within a standard mounting block. This concentration of copper is known as box fill, and it directly affects safety and reliability.

AS/NZS 3000 requires that conductors are not damaged by mechanical pressure and that terminations are not strained. In practice, this means disciplined cable preparation. Sheaths should be stripped back only to the entry point, conductors folded neatly rather than compressed, and excess length avoided. Active looping is a common pressure point. Bridging the supply across three mechanisms using twisted conductors creates bulk and stiffness. Professional installers instead use dedicated looping terminals or compact connectors that distribute the active cleanly without creating a solid mass behind the switches. Adequate wall box depth is also essential. Shallow cavities force cables hard against the rear of the mechanisms, increasing heat and long-term failure risk.

Switching Logic and Circuit Types

A 3 gang switch is rarely three simple one-way switches. One or more gangs are often part of multi-way switching arrangements. Hallways, stairwells, and large rooms frequently require two-way or intermediate switching, adding complexity to the termination process.

Each mechanism type has distinct terminals. One-way switches use active and switched active only. Two-way switches introduce common and strapper terminals. Intermediate switches cross strappers to allow control from three or more locations. In a 3 gang assembly, placing the correct mechanism in the correct grid position is critical. Clear terminal markings and consistent orientation reduce wiring errors and simplify fault-finding. Professional-grade mechanisms provide generous terminal access and clear labelling, which is particularly valuable when multiple circuit types are combined behind one fascia.

LED Loads and Inrush Current

Modern lighting loads impose stresses that older switch designs were never intended to handle. LED drivers generate high inrush currents at the moment of switch-on. While the steady-state current may be low, the instantaneous surge can be dozens of times higher.

When a 3 gang switch controls three LED circuits simultaneously, the combined inrush can be significant. Inferior mechanisms with thin contact materials are prone to contact welding, where the contacts fuse together and the switch fails in the on position. High-quality mechanisms mitigate this risk through rapid snap-action springs and silver-nickel contact alloys that resist arc erosion. Specifying mechanisms rated for LED or inductive loads is essential in any multi-gang configuration, particularly in kitchens, garages, and commercial spaces with high fitting counts.

Thermal Considerations in Multi-Gang Plates

Although each switch generates only minimal heat, three mechanisms operating side by side create a localised thermal environment. This is especially relevant if one or more gangs are dimmers or electronic controls.

Heat dissipation depends on airflow behind the plate and the thermal properties of the materials used. Crowded cables, poor dressing, or installation against insulated walls can trap heat. Best practice avoids combining multiple dimmers in a single 3 gang plate and instead uses push-button controls linked to remote dimming modules. Where electronic devices are unavoidable, derating guidelines must be followed to ensure components operate within their thermal limits.

Orientation, Ergonomics, and User Experience

The physical orientation of a 3 gang switch influences usability. Vertical layouts are common near doorways, while horizontal layouts are often specified above benches or splashbacks to align with joinery and tile lines.

Professional systems allow mechanisms to be rotated within the grid so that switch operation remains intuitive regardless of plate orientation. Consistent tactile feedback, predictable switch direction, and logical grouping all contribute to a positive user experience. Poor layout leads to trial-and-error switching, undermining the purpose of zoned control.

Material Quality and Longevity

With three apertures cut into a single fascia, the remaining material between mechanisms is relatively thin. Low-grade plastics can crack, discolour, or deform under repeated use or UV exposure.

High-quality 3 gang switches are moulded from UV-stabilised polycarbonate or ASA, materials chosen for impact resistance and colour stability. This ensures the switch maintains its appearance and protective function throughout the life of the fit-out, even in sunlit rooms or high-traffic commercial environments.

Compliance and Supply Chain Assurance

Every switch installed in Australia must comply with AS/NZS 3133 and carry the Regulatory Compliance Mark. Non-compliant accessories present a serious safety risk and expose installers and owners to liability.

Specialist electrical wholesaler play a key role in maintaining compliance. They supply certified components, compatible mounting accessories, and technical guidance on derating and configuration. Access to a complete, tested system reduces installation risk and ensures consistent performance across the project.

Conclusion

The 3 gang switch is a cornerstone of modern Australian lighting design. It enables sophisticated zoning while preserving clean architectural lines. Achieving this balance requires more than simply fitting three switches behind one plate. Proper cable management, correct mechanism selection, attention to LED inrush behaviour, and use of robust modular systems are all essential. By applying these principles and specifying proven hardware from manufacturers such as Schnap Electric Products, industry professionals can deliver installations that are safe, compliant, and intuitive to use. In the science of lighting control, thoughtful consolidation defines quality.

Recent posts

Electrical Wholesaler

SCHNAP is Australia's premier electrical wholesaler and electrical supplies, marketing thousands of quality products from leading brands. Trusted for nearly two decades by licensed electricians, contractors, and engineers, our range covers everything from basic electrical components to complex industrial electrical equipment

Top Electrical Wholesaler

Our key categories include: LED lighting, designer switches, commercial switchboards, circuit protection, security systems & CCTV, and smart home automation

Online Electrical Wholesaler

All products are certified to Australian standards (AS/NZS), backed by our 30-day, no-questions-asked return policy. Our expert technical team helps you quickly source the right solution for any residential, commercial, or industrial project, with daily dispatch from our Sydney electrical warehouse delivering Australia-wide

Best Electrical Supplies

SCHNAP offers the most comprehensive electrical product range, with full technical specifications, application details, installation requirements, compliance standards, and warranties — giving professionals total confidence in every purchase

Customer Support

Information

Contact Us

-

-

-

-

Mon - Fri: 6:30AM to 5:00PM

-

Sat: 8:00AM to 2:00PM

-

Sun: 9:00AM to 2:00PM

-

Jannali Branch:

-

-

Closed for Renovations

© 2004 - 2026 SCHNAP Electric Products