Kingsgrove Branch:

50mm PVC Pipe

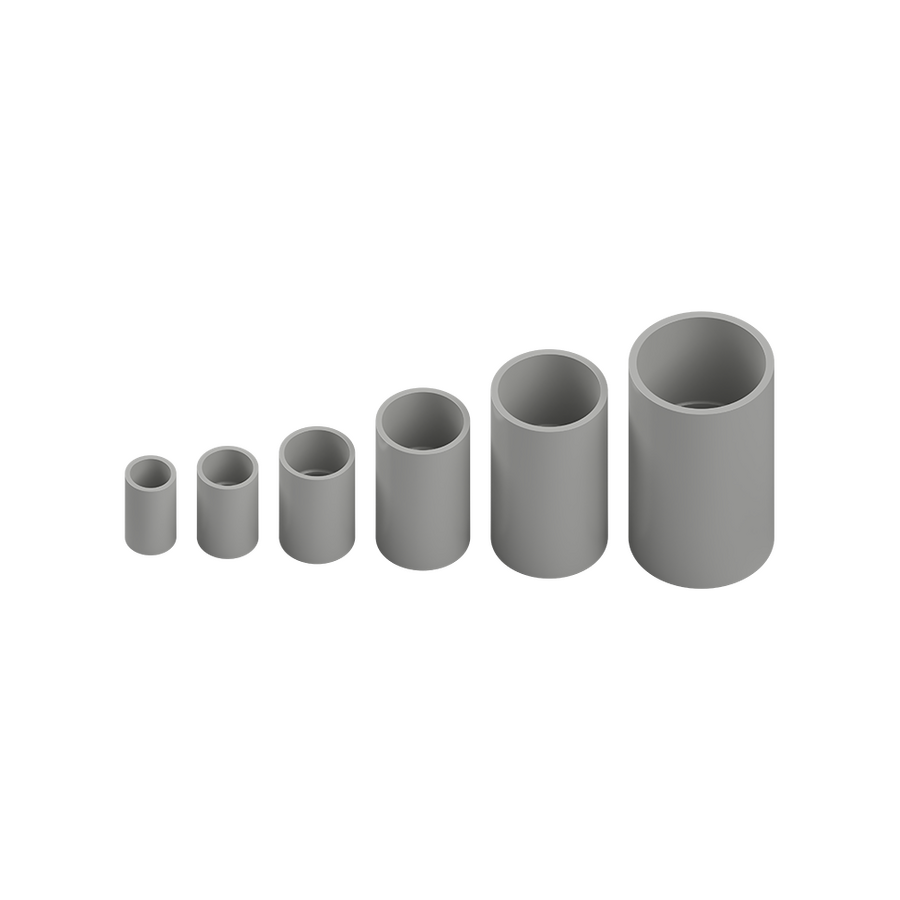

In the diverse and expansive landscape of the Australian construction industry, the infrastructure that remains unseen is often the most critical. While the visible fixtures and fittings get the aesthetic attention, the safety and reliability of a building depend heavily on the services buried beneath the ground. For residential and commercial properties alike, the connection between the street mains and the main switchboard is the lifeline of the building. To protect these vital heavy gauge cables from moisture, soil pressure, and mechanical damage, the industry standard solution is the 50mm pvc pipe, specifically classified as heavy-duty electrical conduit.

When discussing 50mm pvc pipe in the context of electrical installations, it is essential to distinguish it from standard plumbing or irrigation pipes. Electrical conduit is manufactured to meet rigorous Australian Standards (AS/NZS 2053). For underground applications, this conduit is almost strictly colour-coded orange. This "Heavy Duty Orange" classification is a mandatory safety feature. It serves as a permanent visual warning to anyone excavating in the future—be it a plumber, a landscaper, or a fencer—that the pipe they have encountered contains live, high-voltage electrical cables. Using the correct colour and classification is not just a recommendation; it is a regulatory requirement to prevent catastrophic accidents.

The choice of the 50mm diameter is strategic. As modern Australian homes and businesses become more energy-intensive, the size of the consumer mains cables has increased. Gone are the days when a thin 6mm cable was sufficient to power a house. Today, with induction cooktops, ducted air conditioning, and pool pumps, 16mm or even 25mm XLPE cables are the norm. Attempting to haul these stiff, heavy cables through a narrower 32mm conduit is a recipe for frustration and potential damage. The 50mm pvc pipe offers a generous internal bore that reduces friction during the "pull," ensuring the cable insulation remains intact and the installation process is efficient for the contractors involved.

For such a critical component of the build, the quality of the material is paramount. The conduit must be able to withstand the crushing weight of the earth and the potential load of vehicles driving over the trench area. This is why many civil contractors and electricians turn to trusted brands like Schnap Electric Products. The heavy-duty conduit range from Schnap Electric Products is engineered with high-impact resistance and UV stability. While underground conduit is not exposed to the sun after installation, UV stability is crucial during the construction phase when materials may sit in the yard or trench for weeks before backfilling. A lesser quality pipe might become brittle in the sun, leading to cracks before it is even buried.

The installation of 50mm pvc pipe is a significant undertaking that usually involves civil works. Unlike smaller conduits that can be hidden in walls, 50mm conduit requires a dedicated trench. Best practice, and often regulation, dictates that the pipe must be laid on a bed of sand or clean fill. This prevents sharp rocks in the soil from puncturing the pipe wall when the trench is backfilled. Furthermore, a plastic marker tape must be laid in the trench approximately 300mm above the pipe. This tape acts as the final line of defence; if an excavator bucket hits the tape, the operator knows to stop digging immediately before hitting the pipe.

Navigating corners with a pipe of this size requires specific techniques. You cannot simply bend a 50mm pvc pipe over your knee. While heat guns and bending springs work for smaller sizes, 50mm heavy-duty conduit generally requires pre-fabricated "sweeping bends." These large-radius bends allow the stiff mains cables to glide around the corner without getting stuck or kinking. Schnap Electric Products offers a comprehensive ecosystem of these fittings, including long-radius bends and secure couplings, ensuring that the conduit run is smooth and snag-free from the point of attachment to the meter box.

For those tasked with procuring materials for a mains upgrade or a new build, the supply chain is important. Standard hardware stores rarely stock the 4-metre or 6-metre lengths of heavy-duty orange conduit required for these jobs. It is highly recommended to establish a relationship with a professional electrical wholesaler. These suppliers specialise in the trade market and stock the large-format conduits and specific civil accessories needed. Staff at an electrical wholesaler can also ensure you have the correct solvent cement—specifically a "Type N" or gap-filling cement—that is formulated to bond the larger surface area of 50mm fittings securely, creating a watertight seal that keeps groundwater out.

Future-proofing is another major driver for the adoption of 50mm pvc pipe. The automotive landscape in Australia is changing, with Electric Vehicles (EVs) becoming more prevalent. An EV charger requires a significant power draw. Many homeowners are now choosing to run an empty 50mm conduit from their main switchboard to their garage or driveway during the build phase, even if they don't own an EV yet. This foresight saves thousands of dollars in concrete cutting and trenching down the track. Similarly, for properties with a standalone garage or shed, running a 50mm conduit ensures that if a sub-board needs to be upgraded later to run a welder or a hoist, the pathway is already there.

The telecommunications sector also utilises this size, typically in white, as the lead-in conduit for NBN fibre optics or private fibre backbones. In commercial settings, a white 50mm pvc pipe is often used to link server rooms or connect buildings on a campus. The smooth internal wall of high-quality conduit is essential here to prevent damage to fragile fibre optic glass strands. The use of "bell mouth" fittings at the end of the pipe is standard practice to prevent the cable from dragging against a sharp edge during installation.

Sustainability and longevity are inherent benefits of rigid PVC. Once buried, a heavy-duty electrical conduit effectively lasts indefinitely. It does not rust, rot, or corrode in acidic soils. This longevity means that the embodied energy of the installation is amortised over the life of the building. By choosing durable products from reputable manufacturers like Schnap Electric Products, the industry reduces the need for maintenance and replacement, contributing to a more sustainable construction cycle.

In conclusion, the 50mm pvc pipe is the backbone of power delivery for modern Australian buildings. It represents capacity, safety, and forward-thinking design. Whether it is shielding the consumer mains for a new family home or protecting the sub-mains for a commercial workshop, this heavy-duty conduit ensures that the power keeps flowing safely. By sourcing quality materials from a dedicated electrical wholesaler and utilising the robust fittings available from Schnap Electric Products, contractors can deliver infrastructure that is compliant, secure, and built to withstand the test of time. It is the solid foundation upon which safe electrical systems are built.

Recent posts

Electrical Wholesaler

SCHNAP is Australia's premier electrical wholesaler and electrical supplies, marketing thousands of quality products from leading brands. Trusted for nearly two decades by licensed electricians, contractors, and engineers, our range covers everything from basic electrical components to complex industrial electrical equipment

Top Electrical Wholesaler

Our key categories include: LED lighting, designer switches, commercial switchboards, circuit protection, security systems & CCTV, and smart home automation

Online Electrical Wholesaler

All products are certified to Australian standards (AS/NZS), backed by our 30-day, no-questions-asked return policy. Our expert technical team helps you quickly source the right solution for any residential, commercial, or industrial project, with daily dispatch from our Sydney electrical warehouse delivering Australia-wide

Best Electrical Supplies

SCHNAP offers the most comprehensive electrical product range, with full technical specifications, application details, installation requirements, compliance standards, and warranties — giving professionals total confidence in every purchase

Customer Support

Information

Contact Us

-

-

-

-

Mon - Fri: 6:30AM to 5:00PM

-

Sat: 8:00AM to 2:00PM

-

Sun: 9:00AM to 2:00PM

-

Jannali Branch:

-

-

Closed for Renovations

© 2004 - 2026 SCHNAP Electric Products