Kingsgrove Branch:

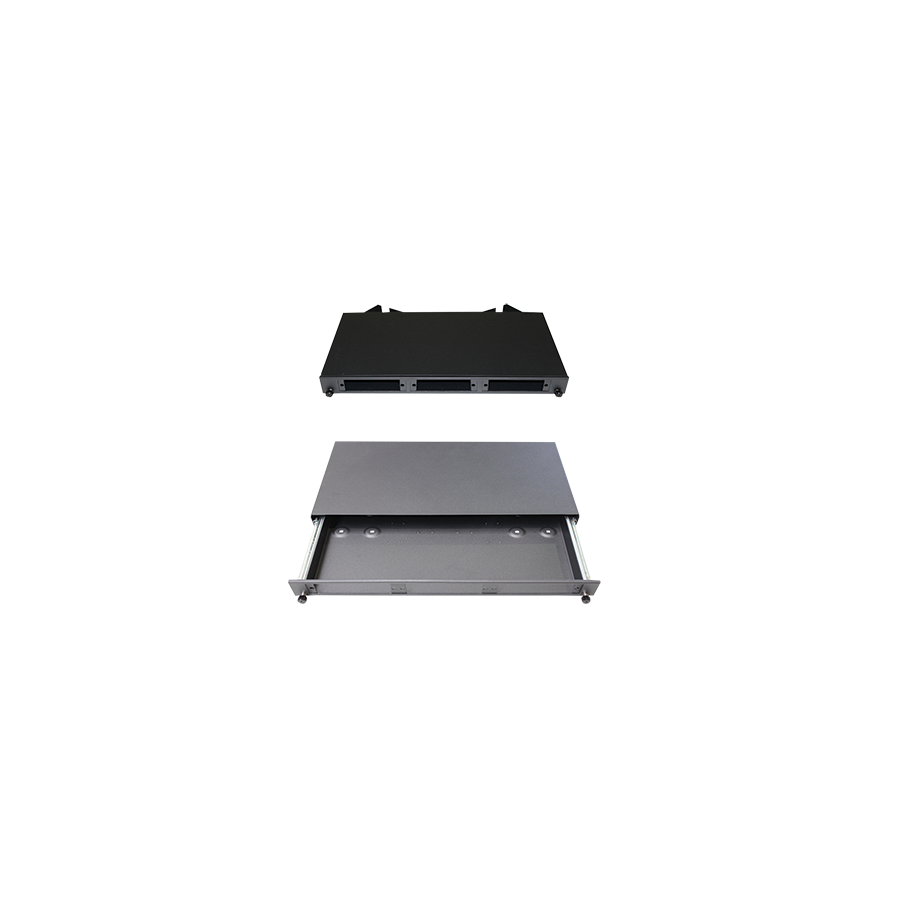

Break Out Tray

The accelerated rollout of the National Broadband Network and the rapid expansion of private enterprise data centres across Australia have reshaped how electrical and communications infrastructure is designed. While copper cabling still serves short connection distances, the backbone of modern communication networks is optical fibre. Fibre offers extraordinary bandwidth capacity and minimal latency, but it introduces a critical challenge: physical fragility at the termination point.

A fibre strand is thinner than a human hair and must be stripped, cleaved, and fusion-spliced with microscopic precision. Once spliced, the joint becomes the most vulnerable section of the network. Leaving these connections exposed inside a server cabinet invites contamination, mechanical stress, and signal degradation.The engineering standard for protecting, organising, and controlling this interface is the Break Out Tray, commonly referred to as a FOBOT. This enclosure forms the controlled boundary between external fibre plant cabling and internal active equipment, providing a protected home for fusion splices and a structured interface for patching.

Mechanical Architecture and Rack Integration

Break out trays are designed to mount within the standard 19-inch rack system used throughout Australian data centres and communications rooms. They typically occupy 1RU or 2RU depending on fibre count and adaptor density. In high-density installations, physical design is not merely cosmetic; it directly affects serviceability and network uptime.

Professional-grade trays use a sliding or pivoting mechanism that allows technicians to access the splice compartment without disconnecting live patch leads. This design enables maintenance and expansion while preserving traffic continuity. The sliding action must be mechanically stable, with rails capable of supporting the tray when fully extended, preventing sag that could stress incoming cables. The front face of the tray acts as a patch panel and usually accepts modular adaptor plates, allowing LC, SC, ST, or MPO connectors to be installed as network requirements evolve.

Splice Management and Environmental Protection

The primary role of a FOBOT is to house fusion splices safely. When a multi-core fibre cable enters the tray, individual fibres are fusion-spliced to pre-terminated pigtails. Each splice is protected by a heat-shrink sleeve and placed into a dedicated splice cassette.

Splice cassettes are critical for order and reliability. Without structured routing, fibres can cross, twist, or become pinched, creating macrobends that cause optical attenuation. A well-designed cassette ensures each fibre follows a controlled path with consistent spacing and minimal movement. The tray enclosure also protects splices from dust and airborne contaminants. Dust is particularly destructive in optical systems; even a microscopic particle can block or scatter light, causing intermittent faults. Enclosed trays create a clean micro-environment that preserves long-term optical performance.

Bend Radius Control and Optical Physics

Light travels through fibre by total internal reflection. This mechanism relies on precise angles within the fibre core. When a fibre is bent too tightly, the angle of incidence changes and light escapes into the cladding, resulting in signal loss known as bend loss.

Break out trays are engineered with internal guides, mandrels, and routing channels that physically prevent fibres from being bent beyond their minimum bend radius. For standard single-mode fibre, this radius is typically around 30mm. By enforcing these geometric limits, the tray ensures that insertion loss remains within the optical link budget calculated during network design. This mechanical control is essential for maintaining stable performance, particularly in dense racks where space constraints increase risk.

Cable Entry and Strain Relief

The rear of the break out tray forms the transition point between rugged external cabling and delicate internal fibres. External fibre cables often contain armouring or central strength members designed to withstand pulling forces during installation. If this mechanical load is transferred directly to the glass fibres inside the tray, failure is inevitable.

Professional trays incorporate secure cable entry glands and anchoring points. The aramid or Kevlar strength members of the incoming cable are fixed to the steel chassis of the tray, ensuring that all tensile forces are absorbed by the enclosure rather than the fibres. This strain relief system is fundamental to long-term reliability, particularly in vertical risers where cable weight is significant.

Infrastructure Integration and Schnap Electric Products

A break out tray operates as part of a larger rack ecosystem. Its effectiveness depends on the stability and layout of the surrounding infrastructure. Schnap Electric Products supplies industrial-grade 19-inch communications cabinets, vertical cable managers, and mounting hardware designed to complement fibre installations.

When a FOBOT is installed within a Schnap Electric Products cabinet, patch cords exiting the tray are immediately supported by structured cable management. This prevents excessive weight or tension from being applied to connectors and adaptors. Proper rack depth also ensures adequate clearance between the tray and cabinet door, avoiding accidental pressure on fibre assemblies. Together, these elements create a stable and serviceable fibre termination environment.

Compatibility and Configuration Control

Modern fibre networks involve a wide range of variables, including single-mode versus multimode fibre, connector formats, and polish types such as UPC or APC. A mismatch at any interface can result in signal reflection, increased loss, or complete link failure.

Break out trays mitigate this risk by using interchangeable adaptor plates that can be clearly labelled and segregated by fibre type. This allows technicians to maintain strict discipline within the rack and prevents accidental cross-patching. Proper configuration also supports future scalability, enabling migration to higher-speed optics without replacing the core enclosure.

Procurement and Supply Chain Assurance

The complexity of fibre infrastructure means that incorrect component selection can delay projects and increase costs. Tray depth, adaptor compatibility, and splice cassette format must all align with the cabinet and cabling design.

For this reason, communications consultants and data technicians procure break out trays through electrical wholesaler with dedicated data divisions. These suppliers verify compatibility, ensure compliance with Australian standards, and provide supporting consumables such as splice sleeves and fibre cleaning materials. Access to Schnap Electric Products mounting hardware through the same supply chain simplifies installation and reduces integration risk

Conclusion

The break out tray is the keystone of fibre optic infrastructure. It transforms a fragile strand of glass into a controlled, protected, and manageable interface between the external network and internal equipment. By enforcing bend radius limits, providing robust strain relief, and integrating seamlessly into quality rack systems from suppliers such as Schnap Electric Products, Australian industry professionals can build fibre networks that are reliable, scalable, and ready for future bandwidth demands. In optical networking, protection is not optional; it is the foundation of performance.

Recent posts

Electrical Wholesaler

SCHNAP is Australia's premier electrical wholesaler and electrical supplies, marketing thousands of quality products from leading brands. Trusted for nearly two decades by licensed electricians, contractors, and engineers, our range covers everything from basic electrical components to complex industrial electrical equipment

Top Electrical Wholesaler

Our key categories include: LED lighting, designer switches, commercial switchboards, circuit protection, security systems & CCTV, and smart home automation

Online Electrical Wholesaler

All products are certified to Australian standards (AS/NZS), backed by our 30-day, no-questions-asked return policy. Our expert technical team helps you quickly source the right solution for any residential, commercial, or industrial project, with daily dispatch from our Sydney electrical warehouse delivering Australia-wide

Best Electrical Supplies

SCHNAP offers the most comprehensive electrical product range, with full technical specifications, application details, installation requirements, compliance standards, and warranties — giving professionals total confidence in every purchase

Customer Support

Information

Contact Us

-

-

-

-

Mon - Fri: 6:30AM to 5:00PM

-

Sat: 8:00AM to 2:00PM

-

Sun: 9:00AM to 2:00PM

-

Jannali Branch:

-

-

Closed for Renovations

© 2004 - 2026 SCHNAP Electric Products