Kingsgrove Branch:

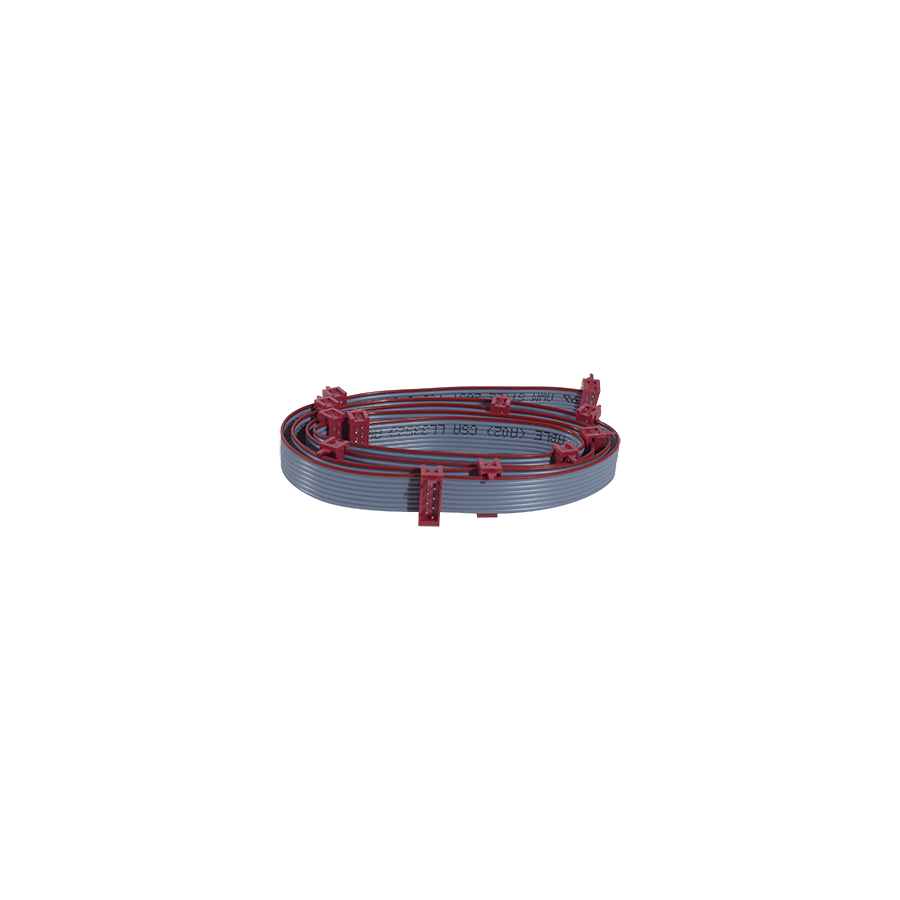

DC Distribution Cable 12 Connectors

In modern Australian security and architectural lighting systems, the distribution of extra low voltage power is a core design discipline rather than a simple wiring task. CCTV camera arrays, access control devices, and LED lighting installations now demand clean, reliable, and scalable power delivery. The traditional approach of supplying each device with an individual plug-pack power adapter is inefficient, visually cluttered, and operationally fragile. It consumes excessive general power outlets, increases failure points, and complicates maintenance.

The professional alternative is centralised power distribution. A single high-quality power supply unit feeds multiple devices through a DC distribution cable with 12 connectors. Often described as a 1-to-12 splitter, this passive assembly allows one high-current DC output to be divided into twelve parallel outputs. While conceptually simple, safe implementation requires an understanding of electrical loading, conductor sizing, connector integrity, and thermal behaviour. When engineered correctly, this solution delivers reliability, consistency, and a clean installation outcome across commercial and security environments.

Current Splitting and Load Engineering

The most important technical consideration in any 12-way DC distribution cable is total current capacity. Each individual output may only supply a modest load, but the main trunk must carry the sum of all connected devices. This aggregated current determines whether the cable operates safely or becomes a point of failure.

Consider a typical CCTV installation using infrared cameras. During night operation, each camera may draw close to one amp as infrared LEDs activate. Twelve cameras operating simultaneously can impose a combined load approaching ten amps. If the main trunk conductor is undersized, resistance increases. This resistance converts electrical energy into heat, causing voltage drop along the cable length. Devices at the far end of the splitter may receive insufficient voltage, leading to camera resets, unstable video, or LED flicker.

Professional DC distribution cables address this by using heavier gauge conductors in the primary trunk. Pure copper conductors in the range of sixteen or eighteen AWG significantly reduce resistance, maintaining stable voltage across all twelve outputs. This design ensures consistent device operation even under full load conditions.

Voltage Drop and System Stability

Voltage drop is not merely a theoretical concern. In extra low voltage systems, small losses have visible and operational consequences. A drop from twelve volts to ten volts may seem minor, but many electronic devices operate within narrow tolerance ranges. When voltage falls below specification, cameras reboot, recorders lose signal, and LED strips display uneven brightness.

The DC distribution cable plays a central role in managing voltage stability. By minimising resistance in the trunk and ensuring consistent conductor quality across all branches, the splitter helps maintain uniform voltage delivery. In longer installations, the splitter can also support power injection strategies, particularly in LED lighting applications, ensuring that voltage remains consistent across extended runs.

Connector Quality and Mechanical Integrity

The physical connection points are just as critical as conductor size. Each DC barrel connector introduces a potential resistance point. Poorly manufactured connectors develop loose contact over time, increasing resistance and generating heat. This can lead to intermittent power loss or complete connector failure.

High-quality DC distribution cables use precisely machined barrel connectors with internal spring contacts that maintain firm pressure on the mating plug. This ensures a stable electrical interface even in environments subject to vibration or movement. At the split junction, professional assemblies incorporate moulded strain relief blocks. These encapsulate the soldered joints and prevent mechanical stress from pulling on individual conductors. This moulding also protects against dust ingress and incidental moisture, extending the service life of the assembly.

CCTV Power Distribution Applications

In security infrastructure, the 12-connector DC distribution cable is widely used to power camera clusters from a centralised power supply or uninterruptible power system. This architecture simplifies maintenance and monitoring. Instead of diagnosing multiple plug packs, technicians focus on a single regulated PSU. Backup power integration is also simplified, as the entire camera system can be supported by one battery-backed source.

However, this approach introduces cable density within cabinets and racks. Twelve parallel leads must be routed cleanly to avoid tangling, stress, or accidental disconnection. Professional installers manage this density using structured cable routing and enclosure accessories. This is where installation hardware from Schnap Electric Products is commonly specified. Slotted ducting, junction boxes, and secure mounting accessories allow the splitter and its output leads to be protected, organised, and tamper-resistant.

LED Lighting and Power Injection

In architectural LED lighting, voltage consistency directly affects visual quality. LED strips powered from a single end often exhibit brightness decay along their length due to voltage drop. This is unacceptable in commercial fit-outs where uniform illumination is expected.

A DC distribution cable with twelve connectors enables distributed power injection. By feeding multiple points along a lighting run, installers can maintain full voltage at each segment of the LED strip. This approach eliminates visible dimming and ensures consistent luminance across the entire installation. For ceiling voids and enclosed spaces, cable insulation must be rated to withstand elevated ambient temperatures without degradation.

Conductor Material Selection

One of the most critical yet often overlooked factors in DC distribution cables is conductor material. Many low-cost assemblies use copper-clad aluminium conductors to reduce manufacturing costs. While visually similar to copper, CCA has significantly higher resistance and inferior thermal performance.

Under high current loads, CCA conductors heat rapidly, increasing the risk of insulation failure and fire. In security and commercial lighting systems, reliability and safety cannot be compromised. Specifying pure copper conductors is essential for any professional installation. Oxygen-free copper provides predictable electrical performance, low resistance, and long-term stability under continuous load.

Procurement and Quality Assurance

The Australian market includes a wide range of DC splitter cables with varying quality levels. Without verification, it is difficult to confirm conductor size, material composition, or connector rating. For this reason, security integrators and electrical contractors source these components through reputable wholesalers.

Professional suppliers provide assemblies tested for current capacity, insulation resistance, and mechanical durability. They also stock complementary installation accessories such as cable mounts, ducting, and fastening systems to ensure the splitter is installed without strain or exposure. This controlled supply chain reduces risk and ensures compliance with Australian electrical safety expectations.

Conclusion

The DC distribution cable with 12 connectors is a foundational component in modern low-voltage system design. It enables the transition from fragmented power delivery to a clean, centralised architecture suitable for CCTV, LED lighting, and access control systems. By calculating total current demand, selecting pure copper conductors, ensuring connector integrity, and managing physical installation with robust infrastructure, Australian professionals can deliver power systems that are stable, safe, and visually disciplined. In extra low voltage engineering, performance is defined not by the power supply alone, but by the quality of the conductors that distribute it.

Recent posts

Electrical Wholesaler

SCHNAP is Australia's premier electrical wholesaler and electrical supplies, marketing thousands of quality products from leading brands. Trusted for nearly two decades by licensed electricians, contractors, and engineers, our range covers everything from basic electrical components to complex industrial electrical equipment

Top Electrical Wholesaler

Our key categories include: LED lighting, designer switches, commercial switchboards, circuit protection, security systems & CCTV, and smart home automation

Online Electrical Wholesaler

All products are certified to Australian standards (AS/NZS), backed by our 30-day, no-questions-asked return policy. Our expert technical team helps you quickly source the right solution for any residential, commercial, or industrial project, with daily dispatch from our Sydney electrical warehouse delivering Australia-wide

Best Electrical Supplies

SCHNAP offers the most comprehensive electrical product range, with full technical specifications, application details, installation requirements, compliance standards, and warranties — giving professionals total confidence in every purchase

Customer Support

Information

Contact Us

-

-

-

-

Mon - Fri: 6:30AM to 5:00PM

-

Sat: 8:00AM to 2:00PM

-

Sun: 9:00AM to 2:00PM

-

Jannali Branch:

-

-

Closed for Renovations

© 2004 - 2026 SCHNAP Electric Products