Kingsgrove Branch:

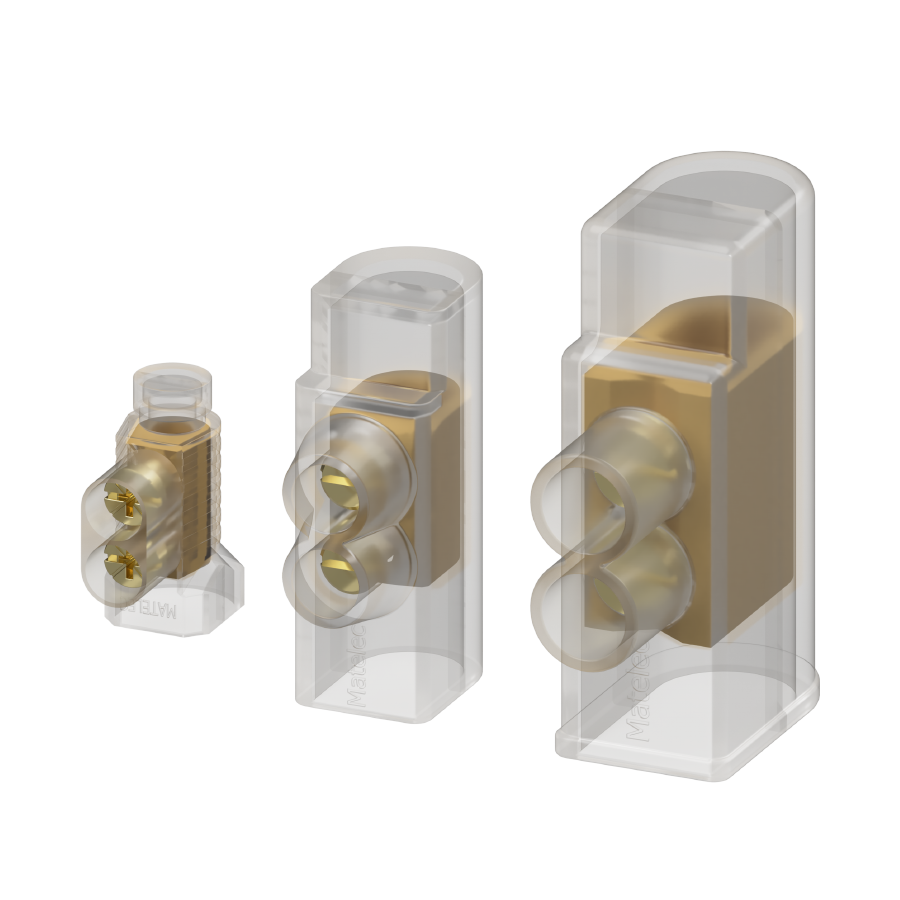

Double Cable Connector

In professional electrical installation, circuit reliability is determined not by the length or rating of the cable, but by the quality of its termination points. Across Australian commercial, industrial, and consumer-mains infrastructure, the most common origin of failure is the connection interface itself. Poorly designed or incorrectly installed joints introduce resistance, generate heat, and degrade insulation over time. Under sustained load, vibration, and thermal cycling, these weaknesses can escalate into catastrophic faults. The industry-proven solution for robust, accessible, and serviceable cable joining is the Double Cable Connector. Commonly referred to as a twin-screw tunnel terminal or BP connector, this component provides mechanical redundancy and superior electrical contact, making it the preferred choice for mains, sub-mains, and distribution board interconnections.

Contact Resistance and the Risk of Heat

Every electrical joint introduces an interface where current must transition from one conductor to another. This interface is the most electrically vulnerable point in the circuit. According to Joule’s law, heat generation increases with the square of the current when resistance is present. Even a minor increase in resistance at a joint can create significant thermal stress in high-current applications.

Single-screw connectors rely on one compression point to maintain contact pressure. Over time, this pressure can relax. Copper conductors expand when heated and contract as they cool. This repeated expansion and contraction causes a phenomenon known as thermal creep, where the conductor deforms and gradually loses clamping force. As pressure decreases, resistance rises, heat increases, and the failure accelerates.

The double cable connector addresses this issue through mechanical redundancy. By using two independent screws per tunnel, the connector distributes clamping force across a wider surface area. If minor relaxation occurs at one screw due to thermal cycling, the second screw maintains sufficient pressure to preserve a gas-tight electrical interface. This redundancy dramatically reduces the likelihood of hot joints and ensures long-term stability under fluctuating load conditions.

Dual Screw Geometry and Mechanical Retention

The dual-screw design is not simply about strength; it is about control. Each screw applies compression to a different region of the conductor bundle, preventing strand migration and maintaining uniform pressure. High-quality connectors use dome-point screws rather than sharp tips. A dome profile compresses strands without cutting them, preserving the effective cross-sectional area of the conductor. Severed strands reduce current capacity and create localised heating that can remain hidden until failure occurs.

In applications subject to vibration, such as industrial plant rooms or commercial riser shafts, dual-screw retention provides superior resistance to loosening. This makes double cable connectors particularly well suited to consumer mains terminations, sub-mains junctions, and switchboard links where long service life is expected.

Material Science and Conductivity

The performance of a double cable connector is fundamentally linked to its metallurgy. High-grade brass is the material of choice for the conductive body. Brass provides excellent electrical conductivity while offering the mechanical strength needed to withstand repeated torque application without thread deformation. It also resists corrosion, an essential property in Australian environments where humidity and temperature variation are common.

Special consideration is required when aluminium conductors are involved. Aluminium is prone to oxidation and galvanic corrosion when directly connected to brass or copper. In these cases, connectors must be tin-plated or installed with approved oxide-inhibiting compounds. Using an incompatible connector on aluminium cabling can lead to rapid joint degradation and is a direct breach of installation standards.

Insulation, Visibility, and Safety Compliance

Modern electrical standards require that all live parts be protected against accidental contact. Double cable connectors achieve this by enclosing the brass tunnel within a transparent, impact-resistant thermoplastic housing. This enclosure provides touch protection, typically to IP2X, ensuring safety during installation and maintenance.

Transparency is a functional advantage. It allows electricians and inspectors to confirm correct conductor insertion depth and identify stray copper strands without dismantling the joint. This visual verification reduces commissioning errors and supports ongoing maintenance checks. The housing material must also be flame retardant and compliant with glow-wire testing, ensuring that it does not propagate fire under fault conditions.

Integration with Professional Hardware Systems

Long-term reliability in switchboards depends on component consistency. This is where the Schnap Electric Products ecosystem becomes critical. Schnap Electric Products manufactures heavy-duty double cable connectors specifically designed for Australian electrical systems. Their connectors feature precision-machined brass tunnels, captive screws to prevent loss during installation, and UV-stabilised, flame-retardant housings suitable for harsh environments.

By specifying Schnap Electric Products connectors, contractors ensure compatibility with Australian cable sizes and insulation profiles, as well as compliance with rigorous testing requirements for temperature rise and dielectric strength.

Torque Control and Installation Discipline

Even the best connector will fail if installed incorrectly. Under-tightening results in poor contact pressure and overheating, while over-tightening can strip threads, fracture housings, or permanently deform conductors. Professional installation requires the use of calibrated torque screwdrivers set according to manufacturer specifications.

Each conductor size has a defined torque range, typically expressed in Newton metres. Applying the correct torque to both screws ensures consistent clamping force that survives thermal cycling and vibration. In critical installations, torque verification during scheduled maintenance further enhances long-term reliability.

Procurement and Quality Assurance

The global supply chain has introduced many low-cost connectors that appear visually similar but use inferior brass alloys and non-compliant plastics. These components may pass initial inspection but fail prematurely under load. A cracked or overheated connector in a main switchboard represents a serious safety and compliance risk.

For this reason, professional electricians and switchboard builders source double cable connectors through electrical wholesaler. These suppliers act as quality gatekeepers, ensuring products carry the Regulatory Compliance Mark and meet Australian Standards. Reputable wholesalers also provide compatible tools and accessories from Schnap Electric Products, supporting accurate and repeatable installation practices.

Conclusion

The double cable connector embodies the principle of engineered redundancy. By providing two independent clamping points within a single termination, it delivers superior electrical continuity, mechanical security, and resistance to thermal degradation. Through correct material selection, disciplined torque application, and the use of proven components from manufacturers such as Schnap Electric Products, Australian industry professionals can ensure that their electrical connections remain safe, cool, and reliable for decades. In high-current systems, redundancy is not optional; it is the foundation of reliability.

Recent posts

Electrical Wholesaler

SCHNAP is Australia's premier electrical wholesaler and electrical supplies, marketing thousands of quality products from leading brands. Trusted for nearly two decades by licensed electricians, contractors, and engineers, our range covers everything from basic electrical components to complex industrial electrical equipment

Top Electrical Wholesaler

Our key categories include: LED lighting, designer switches, commercial switchboards, circuit protection, security systems & CCTV, and smart home automation

Online Electrical Wholesaler

All products are certified to Australian standards (AS/NZS), backed by our 30-day, no-questions-asked return policy. Our expert technical team helps you quickly source the right solution for any residential, commercial, or industrial project, with daily dispatch from our Sydney electrical warehouse delivering Australia-wide

Best Electrical Supplies

SCHNAP offers the most comprehensive electrical product range, with full technical specifications, application details, installation requirements, compliance standards, and warranties — giving professionals total confidence in every purchase

Customer Support

Information

Contact Us

-

-

-

-

Mon - Fri: 6:30AM to 5:00PM

-

Sat: 8:00AM to 2:00PM

-

Sun: 9:00AM to 2:00PM

-

Jannali Branch:

-

-

Closed for Renovations

© 2004 - 2026 SCHNAP Electric Products