Kingsgrove Branch:

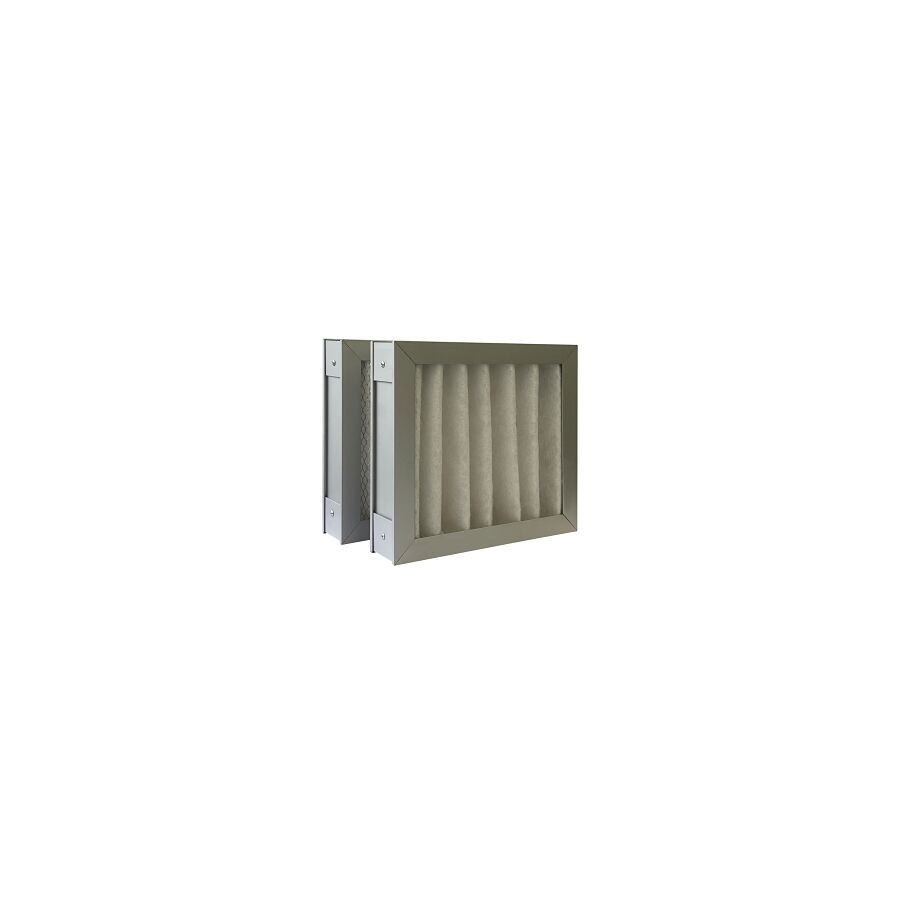

EV Charger Air Filter

The rapid rollout of electric vehicle charging infrastructure across Australia has introduced a new generation of high-power electronic equipment into public and semi-industrial spaces. Modern DC fast chargers and high-power chargers operate at power levels once reserved for substations and heavy industry. While these systems deliver remarkable charging speeds, they also generate substantial waste heat during operation. Even with efficient silicon carbide switching devices, a small percentage of conversion loss at hundreds of kilowatts translates into significant thermal energy that must be managed continuously.

Forced-air cooling remains the primary method for removing this heat from charger cabinets. Large volumes of ambient air are drawn through the enclosure to cool power modules, DC busbars, and control electronics. The quality of that incoming air therefore becomes critical. In Australia’s outdoor environments, air is rarely clean. Dust, salt, moisture, insects, and fine particulates are common. The EV charger air filter is the component that determines whether this cooling strategy succeeds or fails.

Forced Convection and Environmental Exposure

High-power EV chargers rely on forced convection. High-static-pressure fans pull air through intake openings and direct it across heat sinks and internal components. In controlled indoor environments, this air can be filtered and conditioned. Public charging stations, however, are exposed to open roads, construction activity, coastal weather, and regional dust.

Unfiltered air carries particulate matter that settles on heat sinks and circuit boards. Over time, this accumulation forms an insulating layer that reduces heat transfer efficiency. The result is rising internal temperatures even when fans are operating at full capacity. In humid or coastal environments, dust can absorb moisture and become electrically conductive. This introduces the risk of leakage currents, insulation breakdown, and arcing across high-voltage clearances.

The EV charger air filter is designed to intercept these contaminants before they enter the cabinet. Its role is not cosmetic. It is fundamental to electrical safety, thermal stability, and equipment longevity.

Balancing Airflow and Filtration Efficiency

An effective EV charger air filter must balance two competing requirements. It must allow sufficient airflow to maintain cooling performance, and it must capture a high proportion of airborne contaminants. Excessive restriction increases pressure drop, reducing airflow and raising internal temperatures. Insufficient filtration allows dust to bypass the barrier and accumulate on critical components.

High-power charger filters therefore use engineered media rather than generic foam or fabric. The most effective designs employ progressive density layers. Coarser fibres on the intake side capture larger debris such as insects and leaves. Finer fibres deeper in the media trap small dust particles. This depth-loading approach increases dust-holding capacity without creating a rapid rise in pressure drop.

Hydrophobic Media and Weather Resistance

Australian charging infrastructure must withstand heavy rain, high humidity, and occasional flooding. Filter media that absorbs water quickly becomes a liability. When fibres swell with moisture, airflow resistance increases sharply. Fans must work harder, and cooling performance deteriorates. In extreme cases, saturated filters can block airflow entirely, forcing the charger into protective shutdown.

Professional EV charger air filters use synthetic, hydrophobic fibres that repel water. These materials shed rain and resist moisture absorption, maintaining airflow even during severe weather. Thermal bonding of fibres improves structural integrity and prevents deformation under high air velocity. The result is consistent performance across a wide range of environmental conditions.

Thermal Derating and Charging Performance

Modern EV chargers continuously monitor internal temperatures. Sensors are placed on power modules, DC busbars, and control boards. When temperatures approach defined thresholds, the charger’s control system reduces output power to protect components. This behaviour is known as thermal derating.

A clogged or degraded air filter accelerates this process. Reduced airflow leads to higher internal temperatures even at moderate ambient conditions. The charger responds by throttling current. For the end user, this appears as unexpectedly slow charging. A charger rated at three hundred kilowatts may deliver a fraction of that power despite being technically operational.

From the perspective of a charge point operator, this directly affects user satisfaction and site utilisation. Complaints of “slow chargers” are often traced back to neglected air filters rather than electrical faults. In this context, the air filter is a performance-critical component, not a consumable afterthought.

Integration with Cabinet Ventilation Systems

The air filter does not operate in isolation. It is part of a complete ventilation loop that includes intake openings, fans, internal airflow paths, and exhaust louvres. Each element must be correctly specified to maintain thermal balance.

Filter housings must be mechanically robust and maintain ingress protection ratings against dust and water. Poorly designed housings allow bypass airflow, rendering the filter ineffective. Exhaust paths must provide sufficient open area to prevent back pressure. Fan selection must account for the pressure drop introduced by the filter at end-of-life loading conditions.

This is where cabinet accessories from Schnap Electric Products are commonly specified. Ventilation units, outlet filters, exhaust grilles, and thermostatic controls are used together to maintain controlled airflow. Thermostats allow fans to operate only when internal temperatures rise, reducing unnecessary air intake during idle periods and extending filter service life.

Condition-Based Maintenance and Monitoring

Fixed maintenance intervals are rarely optimal for outdoor charging infrastructure. A charger near a highway, construction zone, or unsealed car park will accumulate dust far faster than one in a sheltered urban garage. Changing filters on a calendar basis either wastes resources or risks performance loss.

Condition-based maintenance offers a better approach. Differential pressure monitoring across the filter provides a direct indication of loading. As dust accumulates, the pressure drop increases. When a predefined threshold is reached, the system can generate an alarm or maintenance notification. This ensures filters are replaced precisely when needed, preventing thermal derating without unnecessary service visits.

Some charging platforms integrate these alerts into central management systems, allowing operators to prioritise maintenance based on actual need rather than guesswork.

Fire Safety and Material Compliance

Air filters installed in high-power electrical cabinets must also meet fire safety requirements. Poor-quality materials can ignite or propagate flame if exposed to electrical faults or hot surfaces. Professional EV charger air filters use fire-retardant media that meets recognised flammability standards. This reduces risk in fault scenarios and supports overall enclosure safety certification.

Replacement Media and Compatibility

Not all filter media is interchangeable. Using generic foam or incorrect fibre density can compromise airflow or filtration. Oversized pores allow fine dust to pass through. Excessively dense media restricts airflow and increases fan load.

Replacement filters must match the original specification for size, thickness, and filtration class. Die-cut filters ensure proper sealing within the housing and prevent bypass. In Australia’s varied climate, compatibility with heat, humidity, and UV exposure is also important.

Specialised suppliers provide replacement media designed specifically for high-power chargers used locally. This ensures consistent performance and compliance with manufacturer requirements.

Procurement and Supply Assurance

The EV charger air filter may appear minor compared to power modules and switchgear, but its impact on uptime is significant. Procuring correct filters through knowledgeable suppliers ensures access to appropriate materials, correct dimensions, and verified performance.

A controlled supply chain also supports rapid maintenance response, reducing downtime at critical charging sites. Stocking compatible filters alongside ventilation components simplifies service logistics and helps maintain charging performance throughout the year.

Conclusion

The EV charger air filter is the respiratory system of Australia’s fast-charging network. It allows high-power chargers to operate reliably in dusty, wet, and corrosive environments by protecting sensitive electronics and preserving cooling efficiency. Hydrophobic, progressive-density media, combined with robust housings and intelligent maintenance strategies, prevents thermal derating and extends equipment life. When supported by well-designed ventilation infrastructure and disciplined replacement practices, the air filter enables chargers to deliver full power when drivers need it most. In high-power charging, airflow is not an accessory. It is the foundation of performance and uptime.

Recent posts

Electrical Wholesaler

SCHNAP is Australia's premier electrical wholesaler and electrical supplies, marketing thousands of quality products from leading brands. Trusted for nearly two decades by licensed electricians, contractors, and engineers, our range covers everything from basic electrical components to complex industrial electrical equipment

Top Electrical Wholesaler

Our key categories include: LED lighting, designer switches, commercial switchboards, circuit protection, security systems & CCTV, and smart home automation

Online Electrical Wholesaler

All products are certified to Australian standards (AS/NZS), backed by our 30-day, no-questions-asked return policy. Our expert technical team helps you quickly source the right solution for any residential, commercial, or industrial project, with daily dispatch from our Sydney electrical warehouse delivering Australia-wide

Best Electrical Supplies

SCHNAP offers the most comprehensive electrical product range, with full technical specifications, application details, installation requirements, compliance standards, and warranties — giving professionals total confidence in every purchase

Customer Support

Information

Contact Us

-

-

-

-

Mon - Fri: 6:30AM to 5:00PM

-

Sat: 8:00AM to 2:00PM

-

Sun: 9:00AM to 2:00PM

-

Jannali Branch:

-

-

Closed for Renovations

© 2004 - 2026 SCHNAP Electric Products