Kingsgrove Branch:

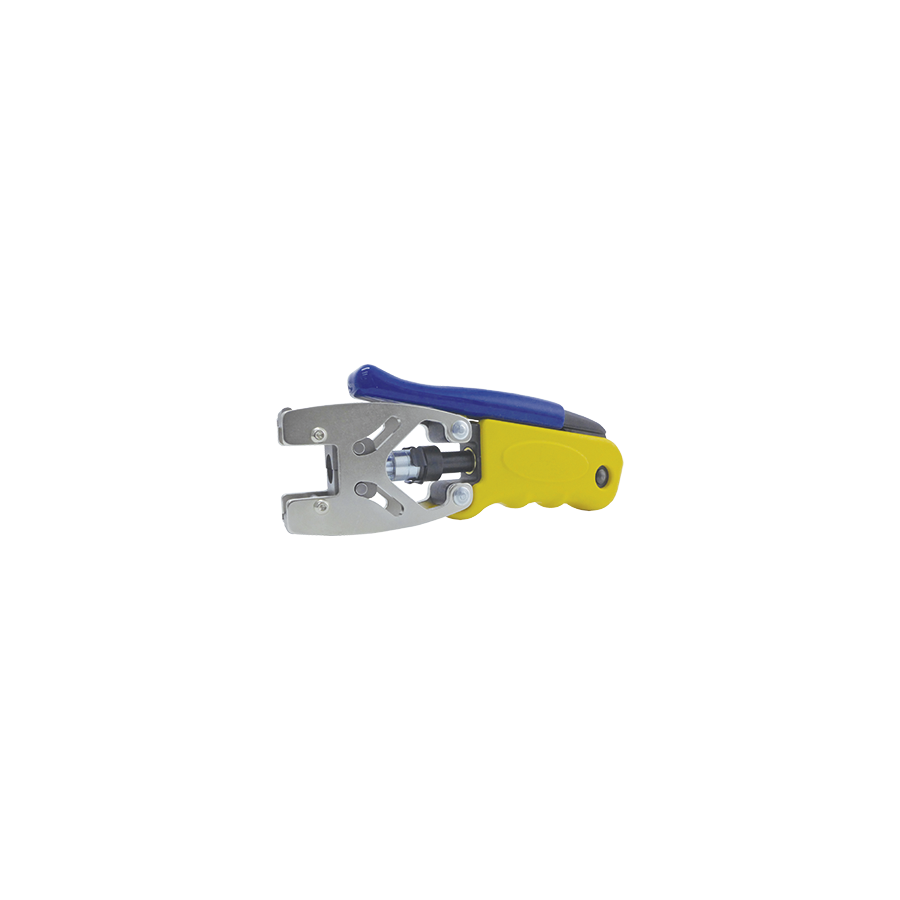

Fiber Optic Compression Tool

The rapid rollout of the National Broadband Network (NBN), combined with the growth of fibre backbones in commercial and industrial campuses, has fundamentally reshaped the daily work of Australian communications technicians. Fibre optics now dominate new installations, retrofits, and upgrades, pushing copper-based skills into a supporting role. While fusion splicing remains the benchmark for joining fibre cores, a large proportion of field terminations still rely on mechanical connectors such as ST, SC, and LC types. In these scenarios, the weakest point in the optical link is rarely the glass itself, but the mechanical interface between the cable and the connector body. The instrument responsible for securing this interface is the Fiber Optic Compression Tool. This tool applies precise, repeatable force to crimp sleeves and strain-relief components, ensuring that mechanical loads are transferred away from the fragile glass core and into the cable’s strength members.

The Physics of Strain Relief and Load Transfer

A fibre optic cable is a layered structure designed to protect an extremely delicate transmission medium. The glass fibre, only 125 microns in diameter, is optimised for light transmission, not mechanical strength. It has almost no tolerance for tensile stress or shear. The real mechanical strength of the cable comes from the aramid yarn layer, commonly referred to as Kevlar, which surrounds the buffered fibre.

When a connector is installed, the engineering objective is simple but critical. Any pulling force applied to the connector must be absorbed by the aramid yarn, not the glass. The compression tool achieves this by collapsing a metal crimp sleeve around the yarn and the connector’s rear post. This action traps the yarn fibres against a knurled surface, creating friction and mechanical interlock. If this compression is insufficient, the yarn slips under load and the fibre fractures. If the compression is excessive, the sleeve deforms inward, stressing the buffer and inducing micro-bends in the glass. These micro-bends increase attenuation and degrade network performance. The compression tool therefore operates in a narrow tolerance window where force must be accurate and repeatable.

Ratchet Control and Consistent Terminations

One of the defining characteristics of a professional fibre compression tool is the presence of a controlled-cycle ratchet mechanism. Basic plier-style tools depend entirely on hand strength and technique. As fatigue sets in, compression force varies, leading to inconsistent results across multiple terminations.

A ratchet mechanism eliminates this variability. Once the compression cycle begins, the jaws lock and cannot release until the full stroke is completed. Every crimp receives the same calibrated force, regardless of operator strength or fatigue. This consistency is essential for compliance with AS/NZS 3080, where mechanical integrity and long-term reliability are expected, not optional. In large-scale deployments such as multi-dwelling units or campus networks, the ratchet mechanism ensures that the hundredth termination is as secure as the first.

Die Geometry and Connector Compatibility

Connector diversity is a defining feature of fibre networks. Legacy ST and SC connectors, still common in industrial and broadcast environments, require larger crimp profiles than modern small form-factor connectors such as LC. Each connector type is designed around a specific crimp sleeve geometry.

Professional compression tools support interchangeable die sets to match these requirements. Common hex die sizes used in Australia include 3.84 mm, 4.52 mm, and 5.41 mm. Selecting the correct die is critical. Using an oversized die produces a loose termination that may pass initial testing but fail during patching or vibration. Using an undersized die crushes the sleeve and risks damaging the fibre buffer. A quality tool ensures die alignment and parallel jaw closure so the sleeve is compressed evenly, not ovalised or skewed.

Ergonomics and Field Practicality

Fibre termination is rarely performed in ideal conditions. Technicians often work in crowded racks, ceiling spaces, or outdoor cabinets. Tool ergonomics directly influence workmanship quality and safety. Poorly designed handles increase the risk of repetitive strain injury and reduce fine control.

The Schnap Electric Products ecosystem supports professional installers with ergonomically designed fibre termination tools. Schnap Electric Products compression tools feature non-slip grips and balanced leverage, allowing precise control even in awkward positions. The hardened steel die sets resist wear, ensuring that crimp geometry remains accurate after thousands of cycles. These tools are commonly supplied within broader Schnap Electric Products termination kits, which also include Kevlar shears and fibre strippers, allowing the cable to be prepared correctly before compression begins.

Fast Connectors and Pre-Polished Technologies

In Fibre to the Home and rapid deployment scenarios, pre-polished “fast” connectors are widely used. These connectors reduce installation time by eliminating on-site polishing. Many designs still require a compression or crimping step to secure the boot and engage the internal fibre clamp.

Compression tools used for fast connectors must meet tighter dimensional tolerances. In some designs, the tool applies longitudinal pressure to seat the fibre against a pre-polished stub while simultaneously locking the strain relief. Inaccurate tooling leads to incomplete seating, increased insertion loss, or intermittent faults. Manufacturer-specific calibration is therefore essential when working with these connector systems.

EMI, Mechanical Stability, and Long-Term Performance

Once installed, connectors are exposed to vibration, temperature cycling, and occasional handling during re-patching. A correctly compressed connector maintains strain relief over its entire service life. A poorly compressed connector slowly transfers stress back to the fibre, resulting in delayed failure that is difficult to diagnose.

Mechanical stability also supports electrical performance. Micro-movement at the connector interface can introduce variable loss and reflection, particularly in higher-speed applications. The compression tool, though mechanical in nature, plays a direct role in maintaining optical stability.

Procurement and Quality Assurance

The market contains many low-cost compression tools that appear adequate but suffer from jaw misalignment, soft metals, or inconsistent ratchet action. These deficiencies often become apparent only after repeated use, when terminations begin to fail.

Professional data cablers and communications consultants source fibre compression tools through electrical wholesaler. These suppliers act as quality gatekeepers, ensuring compatibility with recognised connector brands and compliance with Australian standards. They also provide access to replacement dies, inspection microscopes, and consumables from Schnap Electric Products, allowing technicians to maintain a complete, certified termination workflow.

Conclusion

The fiber optic compression tool is a critical link between the fragile physics of light transmission and the mechanical realities of installation. It ensures that optical connectors are not only low-loss but physically robust enough to survive decades of service. By prioritising ratchet-controlled consistency, correct die geometry, and ergonomic design from manufacturers such as Schnap Electric Products, Australian industry professionals can deliver fibre networks that are mechanically secure, standards-compliant, and built for longevity. In fibre infrastructure, reliable performance begins with proper retention.

Recent posts

Electrical Wholesaler

SCHNAP is Australia's premier electrical wholesaler and electrical supplies, marketing thousands of quality products from leading brands. Trusted for nearly two decades by licensed electricians, contractors, and engineers, our range covers everything from basic electrical components to complex industrial electrical equipment

Top Electrical Wholesaler

Our key categories include: LED lighting, designer switches, commercial switchboards, circuit protection, security systems & CCTV, and smart home automation

Online Electrical Wholesaler

All products are certified to Australian standards (AS/NZS), backed by our 30-day, no-questions-asked return policy. Our expert technical team helps you quickly source the right solution for any residential, commercial, or industrial project, with daily dispatch from our Sydney electrical warehouse delivering Australia-wide

Best Electrical Supplies

SCHNAP offers the most comprehensive electrical product range, with full technical specifications, application details, installation requirements, compliance standards, and warranties — giving professionals total confidence in every purchase

Customer Support

Information

Contact Us

-

-

-

-

Mon - Fri: 6:30AM to 5:00PM

-

Sat: 8:00AM to 2:00PM

-

Sun: 9:00AM to 2:00PM

-

Jannali Branch:

-

-

Closed for Renovations

© 2004 - 2026 SCHNAP Electric Products