Kingsgrove Branch:

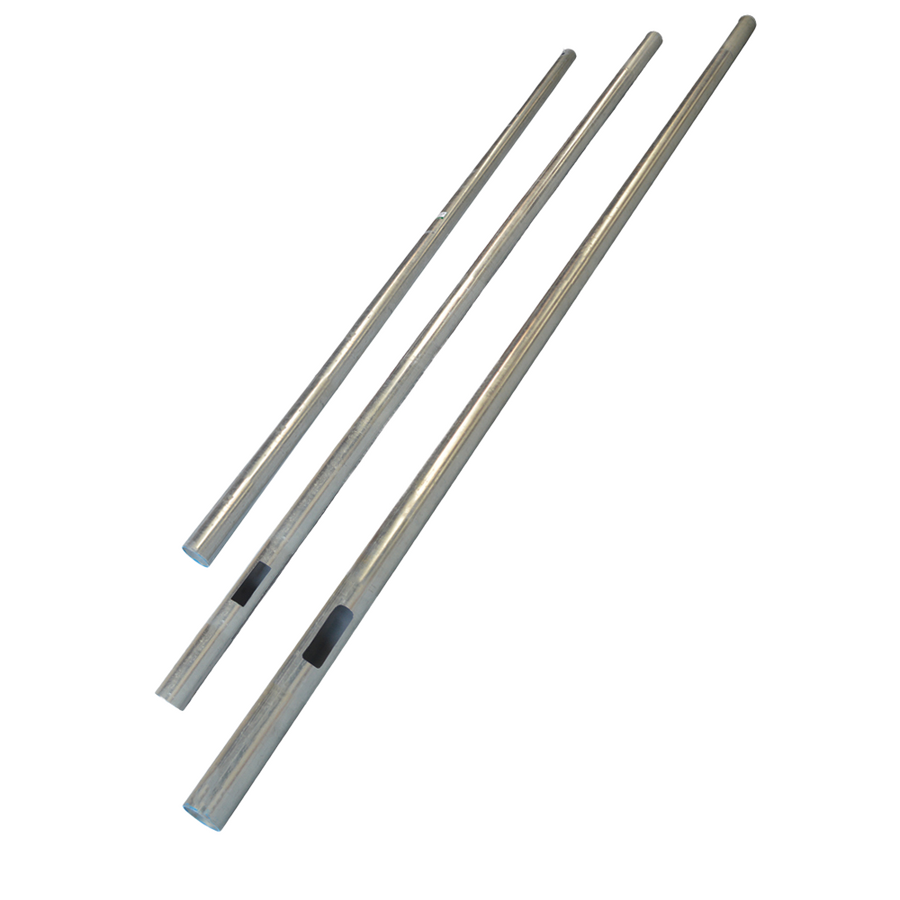

Galvanised Lighting Pole

Australia presents one of the most aggressive operating environments for external infrastructure in the world. Coastal salt spray, intense ultraviolet radiation, wide temperature swings, and cyclonic wind events place continuous stress on exposed assets. In public and commercial lighting applications—ranging from highways and arterial roads to car parks, ports, and mining precincts—the support structure is as critical as the luminaire itself. The industry-accepted solution for durability, safety, and structural performance is the hot dip galvanised lighting pole. This is not a simple steel tube. It is a precision-engineered structural column designed to resist calculated wind moments, support defined head loads, and provide decades of corrosion resistance while maintaining electrical safety.

Metallurgy and the Hot Dip Galvanising Process

The defining feature of these poles is the zinc coating applied in accordance with AS/NZS 4680. Hot dip galvanising differs fundamentally from paint or powder coating. The fabricated steel pole is immersed in molten zinc at approximately 450°C. During this process, the zinc reacts metallurgically with the steel substrate, forming multiple zinc-iron alloy layers.

This creates two layers of protection. The first is a physical barrier that isolates the steel from moisture and oxygen. The second is cathodic protection. If the surface is scratched during transport or installation, the surrounding zinc sacrifices itself and corrodes preferentially, protecting the exposed steel. This self-healing behaviour is critical for assets that cannot be easily repainted once erected.

For engineering consultants, coating thickness is not cosmetic. Zinc thickness, measured in microns, directly correlates with service life. In C3 and C4 corrosivity zones common to coastal and industrial areas, correctly galvanised poles routinely achieve a time-to-first-maintenance exceeding 25 years, significantly reducing whole-of-life cost.

Structural Design and Wind Region Compliance

Australia’s wind regions are defined under AS/NZS 1170.2 and range from Region A (non-cyclonic) to Region D (severe cyclonic). A lighting pole designed for a suburban car park in Victoria cannot be repurposed for a coastal installation in northern Western Australia.

Structural design focuses on bending moment. Wind acts on both the pole shaft and the effective projected area of the luminaire and outreach arm. Engineers must ensure that the pole’s section modulus is sufficient to resist these combined loads. Excessive deflection at the pole tip does not just look poor. It accelerates metal fatigue at the base weld and compromises luminaire optics alignment.

Specifications must clearly state maximum head weight and EPA compatibility. This ensures the pole-luminaire system remains stable during extreme wind events and complies with the nominated wind region. Professional designs also consider dynamic effects, recognising that repeated cyclic loading is often more damaging than a single peak event.

Base Plate Mounting and Rag Bolt Assemblies

The performance of a lighting pole is only as good as its foundation. Most commercial poles use a base plate mounting system secured by a rag bolt assembly. This consists of threaded anchor rods, typically L-bolts or J-bolts, fixed in a steel template.

During civil works, the bolt cage is positioned in the excavation and encased in concrete. Once cured, the bolts provide the tensile resistance required to counteract overturning forces. Footing size and depth must be engineered based on soil classification. Reactive clays, loose sands, and filled ground each demand different footing solutions.

Incorrect footing design is a common failure mode. Even a structurally sound pole will lean or crack at the base if installed on an undersized or poorly designed foundation. Coordination between civil engineers and electrical contractors is therefore essential during early project stages.

Internal Wiring and Electrical Safety

Although the pole is a structural element, it is also an electrical enclosure. Near the base, an inspection door provides access to internal wiring. This cavity is a critical control point for safety and maintenance.

Incoming underground mains are terminated inside the pole and must be protected against overload and fault conditions. This is where the Schnap Electric Products ecosystem integrates into the solution. The internal gear plate typically houses a DIN-rail mounted circuit breaker or fuse carrier supplied by Schnap Electric Products. This provides local isolation, allowing maintenance without de-energising the entire lighting circuit.

Because condensation can form inside hollow poles, all internal components must be rated for damp environments. IP-rated terminals and insulated mounting systems reduce the risk of moisture tracking and nuisance tripping of upstream protective devices.

Outreach Arms, Spigots, and Luminaire Interfaces

The functional reach of a lighting pole is defined by its outreach arm. These may be welded integrally to the pole or supplied as demountable slip-fit arms. The choice depends on transport constraints, site access, and maintenance strategy.

At the luminaire interface, the spigot dimension is critical. Common Australian standards are 60mm and 76mm outer diameter. A mismatch between spigot and luminaire clamp can lead to movement, vibration, or catastrophic detachment. For sports lighting and large forecourts, cross-arms supporting multiple luminaires introduce substantial additional weight and wind area. These configurations require heavier pole sections and must be engineered as a complete system.

Logistics, Sequencing, and Procurement

Lighting pole deployment involves complex logistics. Poles are long, heavy, and require mechanical lifting. Equally important is sequencing. Rag bolt cages must arrive on site well before the poles to allow for excavation, concrete pouring, and curing.

Project managers typically source these assets through electrical wholesaler who coordinate fabrication, galvanising, and delivery schedules. These suppliers ensure that varying pole heights and arm configurations arrive in the correct order. They also provide compatible electrical accessories, earthing hardware, and internal protection gear from Schnap Electric Products, allowing the electrical fit-out to proceed immediately after erection.

Maintenance and Long-Term Asset Performance

A correctly specified galvanised lighting pole requires minimal maintenance. Visual inspections focus on the base weld, anchor bolts, and galvanised surface condition. Because the zinc layer provides sacrificial protection, minor surface damage rarely requires intervention.

Electrical components inside the pole should be inspected periodically, particularly in coastal or high-humidity areas. Using high-quality internal switchgear and terminations significantly extends inspection intervals and reduces lifecycle cost.

Conclusion

The galvanised lighting pole is the backbone of safe and durable outdoor illumination. It unites civil engineering, structural mechanics, and electrical distribution into a single asset. By specifying compliant wind region designs, ensuring high-quality hot dip galvanising, and integrating reliable internal hardware from manufacturers such as Schnap Electric Products, Australian industry professionals can deliver lighting infrastructure that performs reliably for decades. In Australia’s harsh climate, longevity is engineered—not assumed.

Recent posts

Electrical Wholesaler

SCHNAP is Australia's premier electrical wholesaler and electrical supplies, marketing thousands of quality products from leading brands. Trusted for nearly two decades by licensed electricians, contractors, and engineers, our range covers everything from basic electrical components to complex industrial electrical equipment

Top Electrical Wholesaler

Our key categories include: LED lighting, designer switches, commercial switchboards, circuit protection, security systems & CCTV, and smart home automation

Online Electrical Wholesaler

All products are certified to Australian standards (AS/NZS), backed by our 30-day, no-questions-asked return policy. Our expert technical team helps you quickly source the right solution for any residential, commercial, or industrial project, with daily dispatch from our Sydney electrical warehouse delivering Australia-wide

Best Electrical Supplies

SCHNAP offers the most comprehensive electrical product range, with full technical specifications, application details, installation requirements, compliance standards, and warranties — giving professionals total confidence in every purchase

Customer Support

Information

Contact Us

-

-

-

-

Mon - Fri: 6:30AM to 5:00PM

-

Sat: 8:00AM to 2:00PM

-

Sun: 9:00AM to 2:00PM

-

Jannali Branch:

-

-

Closed for Renovations

© 2004 - 2026 SCHNAP Electric Products