Kingsgrove Branch:

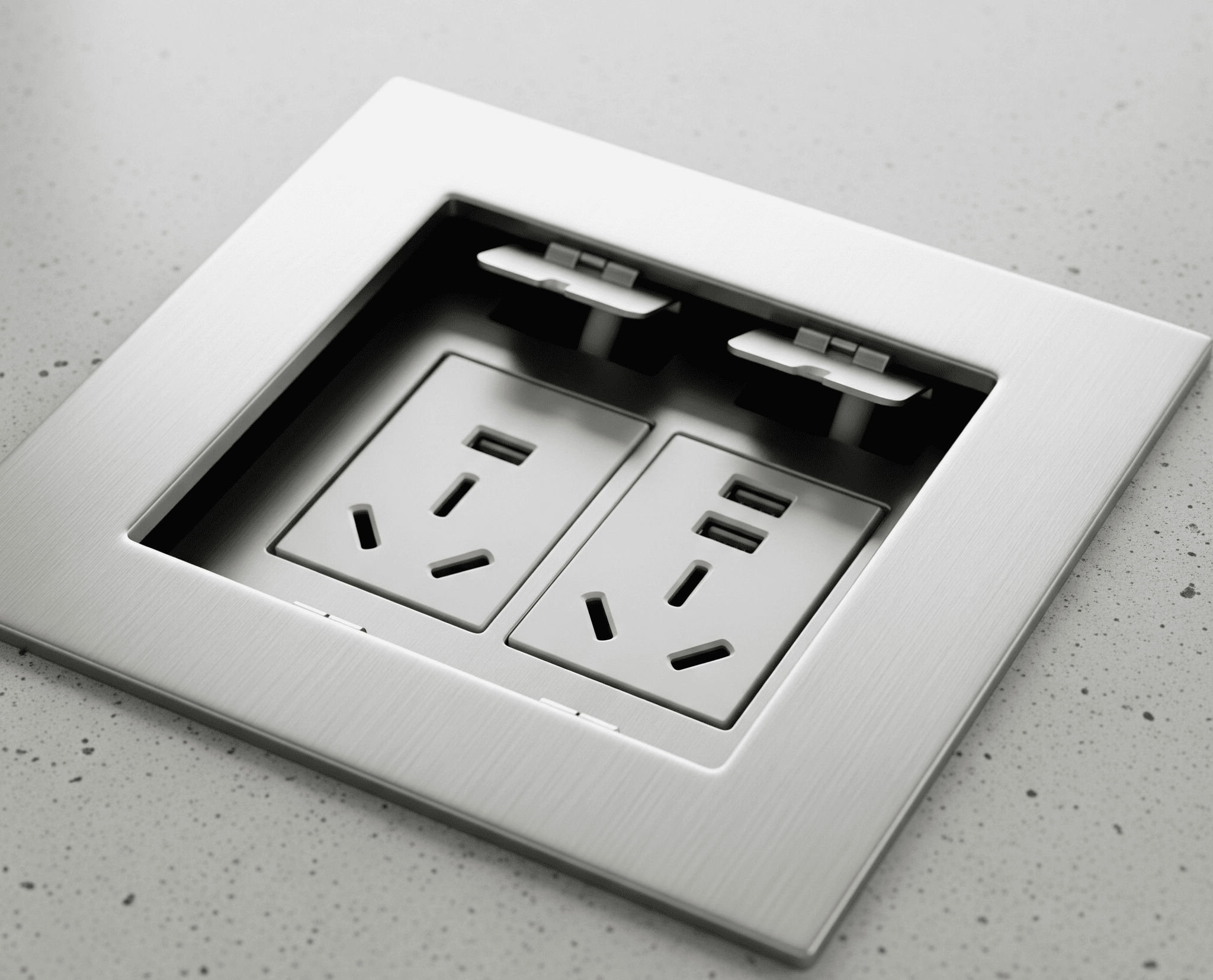

GPO Floor Box

GPO floor box are the unsung heroes of electrical systems. These sturdy enclosures provide a safe and organized space for electrical connections, whether it's a bustling industrial site or a quiet residential setting. From their robust construction to their practical applications, GPO floor boxes are more than just containers; they're the backbone of reliable electrical infrastructure

This comprehensive guide dives into the world of GPO floor boxes, exploring everything from their diverse types and components to installation best practices and essential maintenance tips. We'll also look at safety standards and emerging trends, leaving you well-equipped to handle any electrical challenge

GPO Floor Boxes: A Comprehensive Guide

GPO floor boxes are essential components in electrical systems, providing a safe and organized way to manage power distribution. This guide delves into their various aspects, from fundamental concepts to advanced applications and future trends

Introduction to GPO Floor Boxes

GPO floor boxes are enclosures designed for housing electrical distribution equipment, like circuit breakers and junction boxes, in a safe and accessible manner. They are crucial for industrial, commercial, and residential applications where reliable power distribution is critical. Different types cater to specific needs and environments

-

Functionality and Applications: GPO floor boxes house electrical equipment, providing a protected space for wiring and connections. They are often found in power distribution areas, industrial settings, and commercial buildings

-

Types: GPO floor boxes come in various materials (metal, plastic), sizes, and features, tailored to different environments and power requirements. This flexibility allows for diverse applications, from small installations to large-scale industrial setups

-

Components: Typical components include wiring compartments, terminals for connecting cables, access points for maintenance, and often grounding provisions. The specific components depend on the box's intended use. See USB extension cable

| Material | Dimensions |

|---|---|

| Steel, Aluminum | 600mm x 400mm, 800mm x 600mm |

| ABS, Polycarbonate | 400mm x 300mm, 500mm x 400mm |

Construction and Design Considerations, Gpo floor box

Proper construction is paramount for safety and durability. Careful design ensures easy access, reliable connections, and long-term performance. Materials play a critical role in these factors

-

Construction Techniques: Strong, reliable construction is vital. This involves using high-quality materials, appropriate fasteners, and robust design principles

-

Design Elements: Wiring compartments, terminals, and access points are crucial. Proper design ensures that these elements are easily accessible for maintenance and repairs

-

Materials: Metal offers excellent corrosion resistance, while plastic is often lighter and easier to install. The choice depends on the specific application and its environmental conditions

-

Grounding: Effective grounding is essential to prevent electrical shocks and maintain safety. Follow established grounding procedures for all installations

| Advantages | Safety Considerations |

|---|---|

| Corrosion resistance, durability | Strong grounding connections required |

| Lightweight, easy installation | Proper mounting and protection from physical damage |

Installation and Wiring Procedures

Proper installation is critical for a safe and functioning system. This section details the steps for a smooth and compliant installation

-

Preparation: Ensure the installation area is suitable and all necessary tools are available. Plan the wiring layout for optimal access

-

Mounting: Secure the floor box to the wall or floor using appropriate anchors. Follow manufacturer instructions

-

Cable Connection: Carefully terminate cables using appropriate connectors and methods. Adhere to safety standards and manufacturer guidelines

-

Labelling: Clearly label all connections for easy identification and maintenance. Use a consistent labelling system

| Procedure | Safety Precautions |

|---|---|

| Prepare the mounting area | Use appropriate safety gear |

| Mount the floor box | Ensure secure mounting |

Ending Remarks: Gpo Floor Box

In conclusion, GPO floor boxes are vital components in any electrical system. Their robust design, varied applications, and adherence to safety standards make them indispensable in a multitude of settings. By understanding their construction, installation, and maintenance, you can ensure your electrical systems run smoothly and safely. Hopefully, this guide has provided a solid foundation for your GPO floor box knowledge

Questions and Answers

What are the typical materials used for GPO floor boxes?

Common materials include steel, aluminum, and sometimes plastic, each with varying levels of durability and cost

What are the most important safety considerations during installation?

Proper grounding, cable termination, and adherence to safety regulations are paramount. Always prioritize safety

How often should GPO floor boxes be maintained?

Regular visual inspections, cleaning, and checks for loose connections are recommended to prevent potential issues

What are some common problems that occur with GPO floor boxes?

Overheating, faulty connections, corrosion, and improper grounding are among the most prevalent issues

Electrical Wholesaler

SCHNAP is Australia's premier electrical wholesaler and electrical supplies, marketing thousands of quality products from leading brands. Trusted for nearly two decades by licensed electricians, contractors, and engineers, our range covers everything from basic electrical components to complex industrial electrical equipment

Top Electrical Wholesaler

Our key categories include: LED lighting, designer switches, commercial switchboards, circuit protection, security systems & CCTV, and smart home automation

Online Electrical Wholesaler

All products are certified to Australian standards (AS/NZS), backed by our 30-day, no-questions-asked return policy. Our expert technical team helps you quickly source the right solution for any residential, commercial, or industrial project, with daily dispatch from our Sydney electrical warehouse delivering Australia-wide

Best Electrical Supplies

SCHNAP offers the most comprehensive electrical product range, with full technical specifications, application details, installation requirements, compliance standards, and warranties — giving professionals total confidence in every purchase

Customer Support

Information

Contact Us

-

-

-

-

Mon - Fri: 6:30AM to 5:00PM

-

Sat: 8:00AM to 2:00PM

-

Sun: 9:00AM to 2:00PM

-

Jannali Branch:

-

-

Closed for Renovations

© 2004 - 2026 SCHNAP Electric Products