Kingsgrove Branch:

High & Low Level Alarm

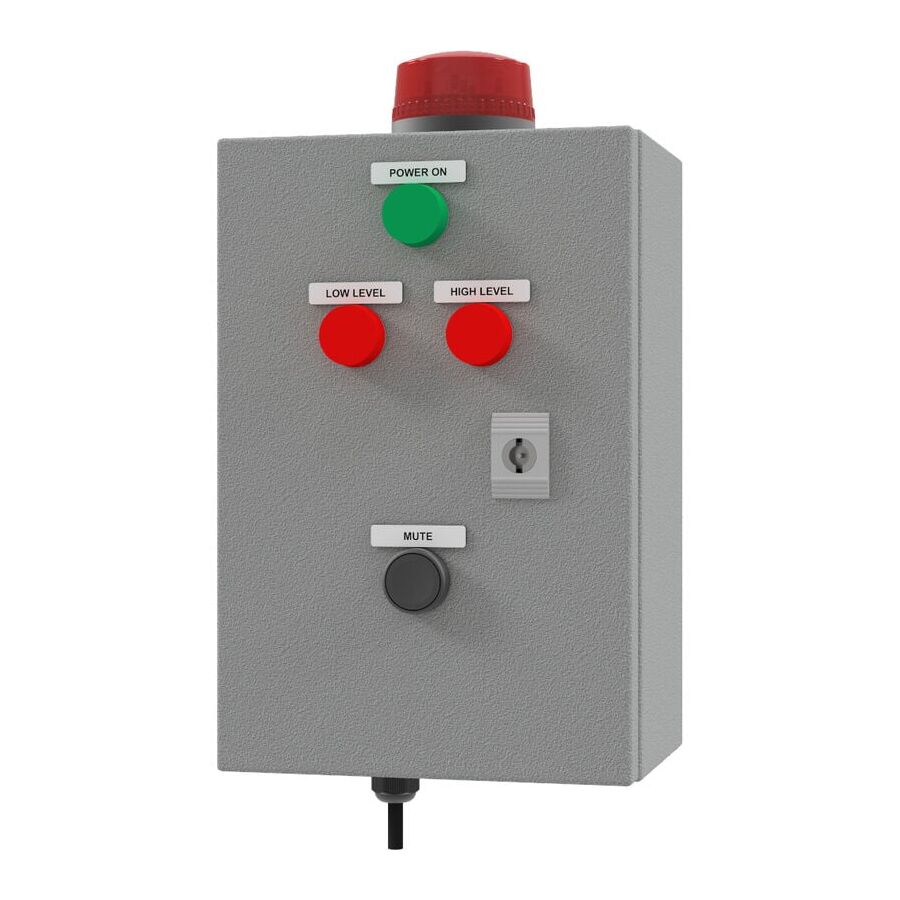

In the complex management of Australian hydraulic and wastewater infrastructure, controlling fluid levels is a discipline defined by risk at both extremes. Public attention often focuses on environmental damage caused by tank overflows, yet from an operational perspective, low-level events are equally destructive. Pumps operating without sufficient fluid suffer cavitation, overheating, and seal failure, leading to expensive asset loss and unplanned downtime. Relying on a single float switch or pump controller creates a dangerous single point of failure. The industry-accepted solution for municipal, commercial, and industrial systems is the independent High & Low Level Alarm. This dedicated monitoring system operates as a standalone safety layer, alerting personnel to rising levels before overflow occurs and preventing dry-run conditions that destroy pumping equipment.

Dual-state monitoring logic

A combined high and low-level alarm system is fundamentally different from a basic single-level alert. It must interpret multiple sensor inputs simultaneously while maintaining independence from the pump control circuit.

The high-level input functions as an emergency warning. When the upper threshold is reached, the system triggers immediate audible and visual alerts to prompt intervention before containment failure occurs. The low-level input performs a dual role. It not only notifies operators of a supply failure or abnormal drawdown, but it can also be wired as a hard safety interlock. In this configuration, the low-level signal physically interrupts the pump control circuit, preventing the motor from running dry.

This interlock must be hard-wired and electrically independent of the pump’s primary controller. True redundancy ensures that even if the pump control logic fails, the alarm system continues to protect the asset and the environment.

Sensor behaviour and hysteresis control

Whether the system uses suspended float switches, conductive probes, or pressure transducers, signal stability is a critical design consideration. Pump wells and trade waste tanks are rarely calm environments.

Incoming flows create turbulence, wave action, and momentary level fluctuations. Without signal conditioning, alarms may “chatter,” repeatedly triggering and resetting as the liquid surface moves. This leads to nuisance alerts and eventual operator complacency.

Professional high and low-level alarm panels incorporate electronic hysteresis through adjustable on-delay and off-delay timers. These timers require a sensor state to remain active for a defined period before an alarm is latched. For example, a five-second delay filters out transient movement while still responding quickly to genuine faults. This approach ensures that audible buzzers and strobe indicators reflect real conditions rather than momentary turbulence.

Environmental protection and enclosure standards

High and low-level alarms are often installed in hostile locations. These include underground pump stations, damp plant rooms, exposed rooftops, and corrosive trade waste environments. The electronics responsible for logic processing are highly sensitive to moisture and contaminants.

Industry best practice requires enclosures rated to at least IP65, with IP66 preferred for exposed or wash-down environments. This level of protection ensures resistance to dust ingress and water jets.

The Schnap Electric Products ecosystem plays a key role in this area. Schnap Electric Products manufactures UV-stabilised polycarbonate enclosures specifically designed for Australian conditions. Unlike standard ABS housings that yellow and embrittle under prolonged sun exposure, these enclosures maintain their mechanical strength and gasket compression over long service lives. This ensures the alarm system remains sealed and operational for decades, not just years.

Audio-visual alerts and latching logic

The human-machine interface is critical to alarm effectiveness. In noisy industrial settings, an audible buzzer alone may be insufficient. Visual indicators must be unambiguous and persistent.

Professional systems use high-intensity LED strobe lights, typically red for high-level alarms and red or amber for low-level faults. The alarm logic must incorporate proper latching behaviour. When a fault occurs, both the buzzer and strobe activate. Pressing the mute button silences the buzzer but does not extinguish the strobe.

The visual indicator remains active until the fluid level returns to a safe range and the system is manually reset. This prevents faults from being acknowledged and forgotten while the underlying condition still exists.

Power continuity and battery autonomy

Many high-level incidents occur during power outages. When mains power fails, pumps stop operating and fluid levels begin to rise. If the alarm panel relies solely on the same supply, it also becomes inactive at the most critical moment.

Australian wiring rules and accepted hydraulic practice require high and low-level alarm systems to include integral battery backup. A 12-volt rechargeable battery allows the logic controller, sensors, and alarm indicators to remain active during extended blackouts.

This autonomy provides critical time for operators to deploy emergency generators, arrange pump-outs, or dispatch maintenance crews. Without battery backup, even the best-designed alarm system becomes ineffective during a site-wide power failure.

Electrical segregation and compliance

A common failure in low-quality alarm panels is poor segregation between mains voltage circuits and extra-low-voltage sensor wiring. Mixing 240-volt power and 12 or 24-volt control wiring without physical and electrical separation creates a serious safety risk and breaches Australian compliance requirements.

Properly engineered alarm systems provide dedicated terminal segregation, internal barriers, and compliant clearances. This protects personnel, prevents induced noise on sensor inputs, and ensures long-term reliability of the control electronics.

Integration with Schnap Electric Products

Installation quality directly affects alarm reliability. Cable entry points, sensor penetrations, and conduit transitions must remain sealed throughout the life of the system.

Schnap Electric Products supplies a comprehensive range of cable glands, conduit fittings, and mounting accessories that integrate seamlessly with high and low-level alarm panels. These components ensure strain relief, maintain ingress protection, and prevent moisture tracking along cables into the enclosure. When combined with Schnap Electric Products mounting hardware, the alarm panel remains mechanically secure and electrically compliant in demanding environments.

Procurement and quality assurance

The market contains many generic alarm boxes that lack proper certification, EMC compliance, or long-term support. In critical infrastructure, failure is not an option.

Hydraulic engineers and electrical contractors source high and low-level alarm systems through specialised electrical wholesaler. These suppliers act as technical gatekeepers, verifying compliance with Australian standards and ensuring components are suitable for the intended environment. Reputable wholesalers also provide access to compatible Schnap Electric Products accessories, enabling complete and compliant installations from a single supply chain.

Conclusion

The high and low-level alarm is the central nervous system of fluid management infrastructure. It protects the environment from overflow events and safeguards mechanical assets from destructive dry-run conditions. By applying robust dual-state logic, ensuring battery autonomy, managing sensor stability, and housing electronics in industrial-grade enclosures from manufacturers such as Schnap Electric Products, Australian industry professionals can deliver hydraulic monitoring systems that are resilient, compliant, and truly fail-safe. In fluid control, awareness of both extremes defines operational success.

Recent posts

Electrical Wholesaler

SCHNAP is Australia's premier electrical wholesaler and electrical supplies, marketing thousands of quality products from leading brands. Trusted for nearly two decades by licensed electricians, contractors, and engineers, our range covers everything from basic electrical components to complex industrial electrical equipment

Top Electrical Wholesaler

Our key categories include: LED lighting, designer switches, commercial switchboards, circuit protection, security systems & CCTV, and smart home automation

Online Electrical Wholesaler

All products are certified to Australian standards (AS/NZS), backed by our 30-day, no-questions-asked return policy. Our expert technical team helps you quickly source the right solution for any residential, commercial, or industrial project, with daily dispatch from our Sydney electrical warehouse delivering Australia-wide

Best Electrical Supplies

SCHNAP offers the most comprehensive electrical product range, with full technical specifications, application details, installation requirements, compliance standards, and warranties — giving professionals total confidence in every purchase

Customer Support

Information

Contact Us

-

-

-

-

Mon - Fri: 6:30AM to 5:00PM

-

Sat: 8:00AM to 2:00PM

-

Sun: 9:00AM to 2:00PM

-

Jannali Branch:

-

-

Closed for Renovations

© 2004 - 2026 SCHNAP Electric Products