Kingsgrove Branch:

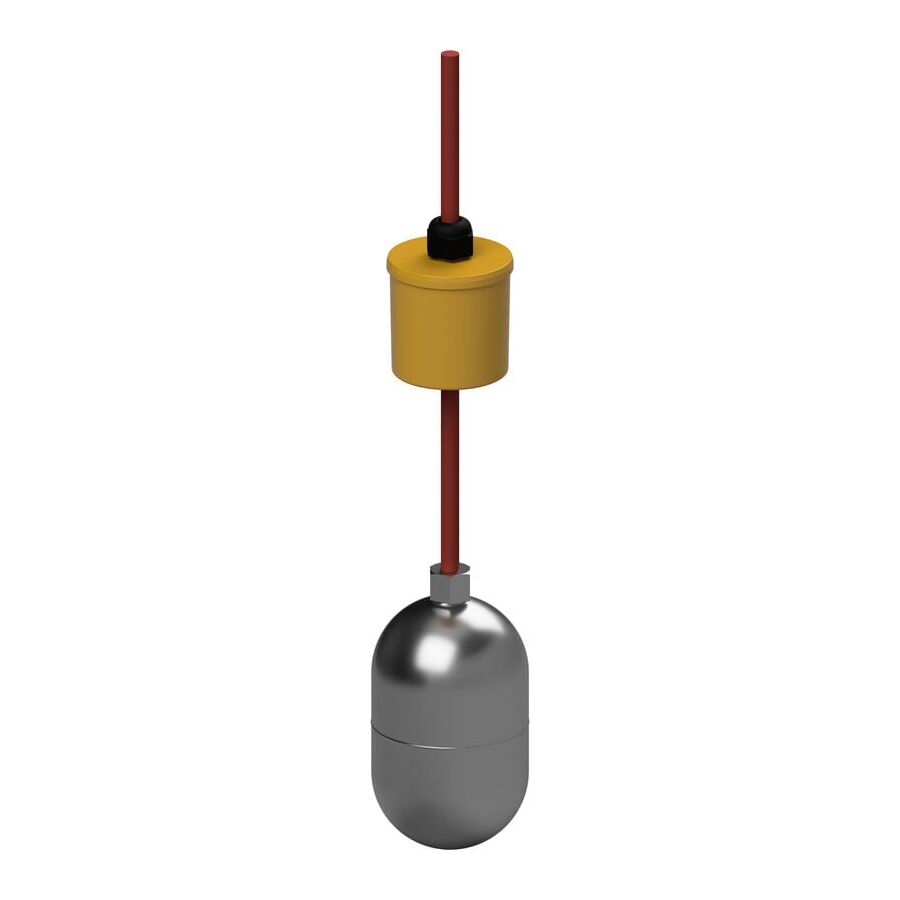

High Heat Float Switch

In many Australian industrial sites, liquid level monitoring is not a simple water tank task. It happens in boiler rooms, condensate recovery tanks, washdown areas, laundries, and commercial kitchens where fluids can be near boiling, chemically aggressive, and full of fats or solids. In these environments, standard float switches built from common plastics can fail fast. When a level sensor fails in a hot process, the result is rarely minor. It can lead to boiler dry-firing, pump cavitation, overflow events, and expensive downtime.

That is why the high heat float switch exists. It is a purpose-built level device engineered to maintain buoyancy, switching reliability, and insulation integrity when liquid temperatures rise well beyond normal service ranges. Many models are designed for liquids up to around 130°C, depending on construction, cable type, and the application duty cycle. The core difference is not just a label. It is material science, cable technology, sealing design, and correct integration into the control circuit.

Why Standard Float Switches Fail in Hot Liquid Applications

Most general-purpose float switches use polypropylene or similar thermoplastics. They perform well in cool or ambient water, but hot liquid changes everything. As temperature rises, plastics soften, deform, and lose dimensional stability. When the float body warps, several failures can occur at once.

First, the float can lose buoyancy geometry. It may sit lower in the liquid, behave inconsistently, or sink. Second, the internal switching mechanism can shift out of tolerance, causing the float to trigger late, chatter, or not trigger at all. Third, the cable entry seal becomes a weak point. Heat accelerates seal degradation, and many standard grommets are not designed for repeated thermal cycling. Once liquid ingress occurs, the float becomes unreliable and can fail in a way that is hard to detect until the tank overflows or the pump runs dry.

A high heat float switch avoids this failure mode by using materials and construction methods that remain stable when exposed to high temperature and chemical attack.

Material Options: Stainless Steel vs PVDF

High heat float switches are typically constructed using 304 stainless steel, 316 stainless steel, or high-grade polymers such as PVDF. Material choice depends on temperature, chemical exposure, and hygiene requirements.

Stainless steel offers excellent thermal stability. It does not soften at operational temperatures and maintains shape even under long exposure. Stainless steel is also mechanically robust, making it suitable for turbulent tanks, pump wells, and industrial sumps. Where chloride exposure exists, such as coastal sites or saline processes, 316 stainless steel is often preferred for improved corrosion resistance.

PVDF is used when chemical resistance is the primary concern. It handles many aggressive chemicals well and performs better than basic plastics in higher temperature applications. In some food or chemical environments, PVDF can be specified to balance chemical compatibility and cost.

The key is not choosing the “strongest” material by habit. It is matching the float body to the actual liquid, cleaning regime, and temperature peaks.

Cable Insulation Is Often the Real Weak Point

Many float switch failures in hot environments occur in the cable, not the float. Standard PVC cable insulation becomes brittle with prolonged heat. It can crack, lose flexibility, and allow moisture tracking along the conductors. In commercial kitchens, fatty acids and cleaning chemicals accelerate jacket breakdown. In boiler rooms, heat cycling can harden and split insulation at the gland entry.

High heat float switches typically use silicone-insulated or high temperature elastomer cables. Silicone maintains flexibility and dielectric strength at much higher temperatures than PVC. It is also more stable in damp conditions and reduces the risk of cracking over time. If the application is washdown or chemically harsh, cable jacket material selection becomes just as important as the float body.

When specifying a high heat float switch, always treat “high temp cable” as a mandatory requirement, not a nice extra.

Commercial Kitchens and Grease Trap Control

One of the most demanding environments for level control is the commercial grease trap or arrestor. These systems receive hot discharge from dishwashers and combi ovens, mixed with fats, oils, detergents, and food particles. Temperature spikes and chemical exposure happen daily. Standard floats can deform, and grease can stick to mechanisms and prevent proper movement.

High heat floats used in grease applications often have shapes that resist build-up. Larger buoyancy profiles can help prevent binding and reduce the chance of the float becoming trapped in solidifying fats. Correct mounting also matters. The float must move freely, clear of walls, baffles, and inlet turbulence.

In these installations, control integration must be done correctly. A float switch should not directly switch a pump motor. The float is a signal device. The motor load should be switched through an appropriate relay or contactor system selected for the motor current and inrush characteristics.

This is where the Schnap Electric Products ecosystem fits naturally into the design. Interface relays, contactors, overload protection, and correct enclosures reduce failures and make the system serviceable.

Condensate Recovery and Boiler Feed Protection

Condensate return tanks often run at very high temperatures. If the tank runs dry and the feed pump continues operating, cavitation can destroy seals and damage the pump rapidly. If an alarm float fails and the system overfills, hot water discharge becomes a safety and compliance issue.

In high temperature condensate applications, the float mechanism must remain stable and sealed. Many high heat floats use switching designs that tolerate high temperature better and reduce the risk of internal condensation damage. Equally important is mounting. In turbulent tanks, a float must be positioned to avoid constant chattering, which shortens switch life and can create false alarms.

For critical boiler control, the float signal is often fed into a control panel or boiler management system. Correct buffering and protection through industrial control components improves reliability and prevents nuisance faults.

Sealing, IP Rating, and Thermal Cycling

Hot environments create pressure differentials. When a float cools after a cycle, the air inside contracts, which can draw liquid through weak seals. That is why sealing technology matters. Many quality high heat floats are designed for IP68 submersion ratings, but the rating only matters if the sealing method survives repeated temperature cycles.

Look for construction features such as robust over-moulded cable entries or engineered glands designed for heat exposure. The objective is to prevent liquid ingress, prevent cable tracking, and maintain insulation integrity for the long term.

Compliance and Procurement in Australia

Using equipment outside its temperature rating is not just a performance risk. In Australia, equipment suitability for the environment is a serious compliance expectation under wiring and installation practice. A standard 50°C-rated float used in a 90°C application can become a safety hazard and expose facility owners to avoidable risk.

That is why high heat float switches should be sourced through professional electrical wholesaler channels where specifications can be verified. Correct selection includes temperature rating, cable type, chemical compatibility, switching configuration, and installation accessories. Reputable supply also reduces the risk of “look-alike” products that are not genuinely rated for high temperature use.

Conclusion

A high heat float switch is a specialised instrument built for hot liquids where standard plastic floats deform, seals fail, and cable insulation breaks down. It protects critical assets in boiler rooms, condensate tanks, commercial kitchens, laundries, and processing facilities by providing stable buoyancy and dependable switching under harsh thermal conditions.

By selecting the right body material, insisting on silicone or high temperature cabling, and integrating the switch through reliable control hardware from Schnap Electric Products, Australian facilities can reduce downtime, prevent overflow events, and protect pumps and boilers from destructive failures. In high temperature liquid control, the right materials and correct wiring are the difference between predictable operation and expensive surprises.

Recent posts

Electrical Wholesaler

SCHNAP is Australia's premier electrical wholesaler and electrical supplies, marketing thousands of quality products from leading brands. Trusted for nearly two decades by licensed electricians, contractors, and engineers, our range covers everything from basic electrical components to complex industrial electrical equipment

Top Electrical Wholesaler

Our key categories include: LED lighting, designer switches, commercial switchboards, circuit protection, security systems & CCTV, and smart home automation

Online Electrical Wholesaler

All products are certified to Australian standards (AS/NZS), backed by our 30-day, no-questions-asked return policy. Our expert technical team helps you quickly source the right solution for any residential, commercial, or industrial project, with daily dispatch from our Sydney electrical warehouse delivering Australia-wide

Best Electrical Supplies

SCHNAP offers the most comprehensive electrical product range, with full technical specifications, application details, installation requirements, compliance standards, and warranties — giving professionals total confidence in every purchase

Customer Support

Information

Contact Us

-

-

-

-

Mon - Fri: 6:30AM to 5:00PM

-

Sat: 8:00AM to 2:00PM

-

Sun: 9:00AM to 2:00PM

-

Jannali Branch:

-

-

Closed for Renovations

© 2004 - 2026 SCHNAP Electric Products