Kingsgrove Branch:

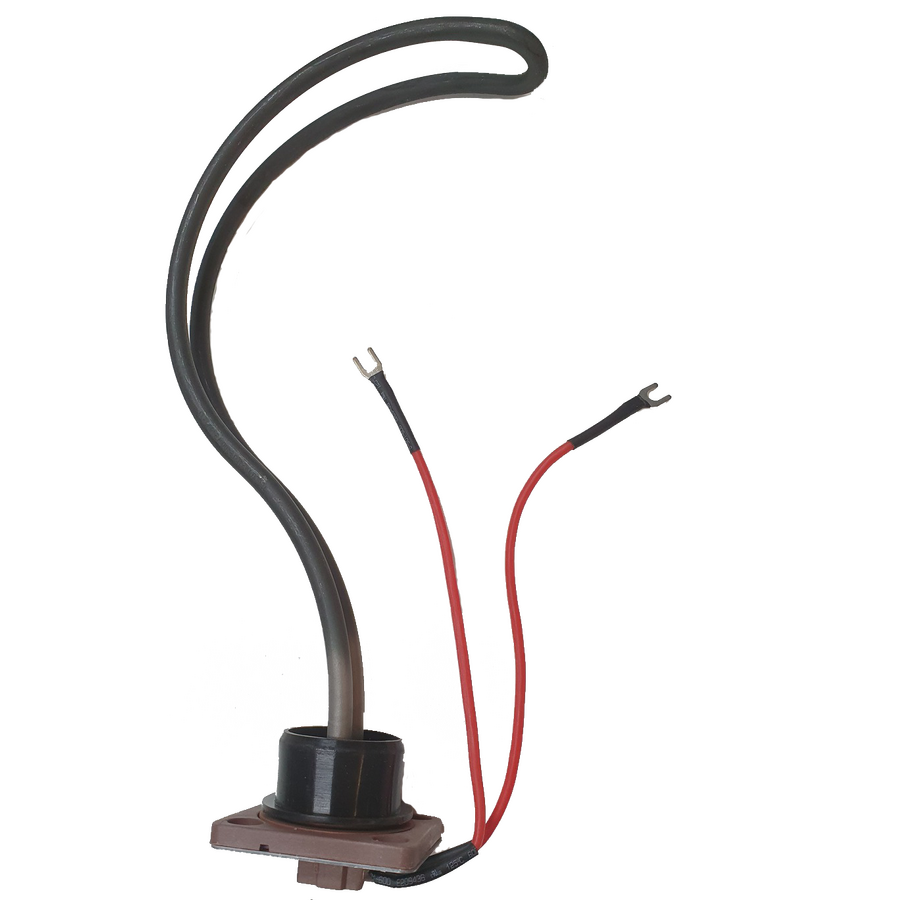

Hot Water Element

Across Australian residential, commercial, and light-industrial infrastructure, electric storage water heaters remain the dominant method for delivering reliable hot water. Despite growing interest in heat pumps and solar thermal systems, the vast majority of installed systems still depend on electric immersion heating for consistent sanitation and hygiene. At the core of this system sits a deceptively simple yet highly engineered component: the Hot Water Element. This device is not merely a coil that heats water. It is a precision resistive load designed to survive extreme thermal cycling, internal pressure, mineralised water, and continuous electrical stress. For plumbers, electricians, and facilities managers, understanding element construction, metallurgy, and failure mechanisms is essential to extending cylinder life, improving efficiency, and preventing unplanned outages.

Joule heating and electrical isolation

The operation of a hot water element is governed by Joule heating, where electrical energy is converted into heat according to the relationship between current, resistance, and power. When current flows through the internal resistance wire, heat is generated uniformly along its length.

The engineering challenge is not generating heat but doing so safely inside a water-filled vessel. The resistive wire, typically a Nickel-Chromium alloy, is centrally positioned within a metallic sheath. The cavity between the wire and the sheath is densely packed with Magnesium Oxide powder. This material performs two critical functions. It conducts heat efficiently from the wire to the sheath while simultaneously acting as a high-grade electrical insulator. Without this dielectric barrier, current would leak into the water, creating a severe electrocution risk and instant element failure.

Sheath metallurgy and water chemistry

The external sheath material defines the service life of the element. Traditional copper-sheathed elements were once common due to copper’s excellent thermal conductivity. However, copper performs poorly in many Australian water conditions. Soft, acidic, or chlorinated water accelerates pitting corrosion, thinning the sheath until it ruptures.

Modern engineering standards favour Incoloy alloys, specifically Incoloy 800 or 825. These nickel-iron-chromium alloys provide exceptional resistance to oxidation, chloride attack, and stress corrosion cracking. In coastal regions and areas with aggressive water chemistry, Incoloy elements significantly outperform copper equivalents. Schnap Electric Products adopts this metallurgy across its professional element range, ensuring compatibility with both domestic and commercial storage cylinders exposed to harsh operating conditions.

Watt density and scale formation

One of the most misunderstood performance variables is watt density. Watt density describes how much power is emitted per unit area of the element surface. High watt density elements heat water quickly but operate at much higher surface temperatures.

In hard water regions, elevated surface temperatures accelerate mineral precipitation. Calcium carbonate forms an insulating crust around the element, commonly referred to as limescale. This scale traps heat inside the sheath, preventing effective heat transfer to the water. As a result, the internal resistance wire overheats, leading to premature burnout or sheath rupture. The element may still draw power but fail to heat effectively, increasing energy consumption before complete failure.

To reduce this risk, professional elements are designed with increased surface area through bent or sickle-shaped profiles. Schnap Electric Products elements use optimised geometries to lower watt density while maintaining required output. This approach slows scale accumulation and significantly extends operational life in mineralised water zones.

Thermostat interface and control accuracy

The element and thermostat operate as a matched system. The thermostat regulates water temperature by cycling power to the element based on probe feedback. Accurate temperature sensing depends on clean thermal transfer between the water, element flange, and thermostat pocket.

When an element becomes heavily scaled or sludge accumulates around the thermostat probe, heat transfer is delayed. This creates control lag, causing water temperature to overshoot before the thermostat cuts out. Repeated overheating stresses the safety over-temperature cut-out and accelerates element degradation.

Correct installation practice requires replacing the sealing gasket every time an element is changed. A compromised gasket leads to slow leaks, corrosion around terminals, and eventual electrical faults. Terminal connections must also be tightened to specification. Loose connections increase resistance, generating localised heat that can melt terminal blocks and cause arcing failures.

Electrical load and system compatibility

Hot water elements are high-current devices. Common ratings in Australian systems include 2.4 kW, 3.6 kW, and 4.8 kW. Selecting the correct wattage is not optional. An oversized element may exceed circuit capacity, trip breakers, or overload off-peak tariffs. An undersized element increases recovery time and user dissatisfaction.

Schnap Electric Products supplies element variants engineered for standard Australian cylinder flanges and electrical configurations. Matching element wattage to supply capacity ensures compliance with AS/NZS wiring rules and maintains stable operation under continuous load conditions.

Failure modes and early warning signs

Element failure is rarely instantaneous. Common indicators include increased heating times, tripped circuit protection, discoloured terminal covers, or audible boiling noises caused by scale insulation. Early replacement prevents secondary damage to thermostats and cylinder linings.

In severe cases, sheath rupture allows water ingress into the MgO insulation. This causes earth leakage, tripping RCD protection. Once moisture penetrates the insulation, the element cannot be repaired and must be replaced immediately.

Procurement and quality assurance

The market contains low-cost elements with insufficient insulation density, inconsistent alloy composition, and poor terminal construction. These products may meet initial resistance values but fail rapidly under real operating conditions.

Licensed trades source elements through specialised electrical wholesalers to ensure compliance with AS/NZS 3100 approval requirements. These suppliers verify alloy certification, watt density specifications, and electrical safety. Reputable wholesalers stock the full Schnap Electric Products element range alongside purpose-built element spanners and sealing kits, enabling correct installation without damaging the cylinder boss.

Conclusion

The hot water element is the engine room of the electric storage system. It operates unseen under constant thermal and electrical stress to deliver one of the most essential services in any building. By prioritising Incoloy metallurgy, managing watt density in response to water chemistry, ensuring proper thermostat integration, and selecting proven components from manufacturers such as Schnap Electric Products, Australian professionals can deliver hot water systems that are efficient, safe, and long-lasting. In applied thermodynamics, reliability begins at the heat source.

Recent posts

Electrical Wholesaler

SCHNAP is Australia's premier electrical wholesaler and electrical supplies, marketing thousands of quality products from leading brands. Trusted for nearly two decades by licensed electricians, contractors, and engineers, our range covers everything from basic electrical components to complex industrial electrical equipment

Top Electrical Wholesaler

Our key categories include: LED lighting, designer switches, commercial switchboards, circuit protection, security systems & CCTV, and smart home automation

Online Electrical Wholesaler

All products are certified to Australian standards (AS/NZS), backed by our 30-day, no-questions-asked return policy. Our expert technical team helps you quickly source the right solution for any residential, commercial, or industrial project, with daily dispatch from our Sydney electrical warehouse delivering Australia-wide

Best Electrical Supplies

SCHNAP offers the most comprehensive electrical product range, with full technical specifications, application details, installation requirements, compliance standards, and warranties — giving professionals total confidence in every purchase

Customer Support

Information

Contact Us

-

-

-

-

Mon - Fri: 6:30AM to 5:00PM

-

Sat: 8:00AM to 2:00PM

-

Sun: 9:00AM to 2:00PM

-

Jannali Branch:

-

-

Closed for Renovations

© 2004 - 2026 SCHNAP Electric Products