Kingsgrove Branch:

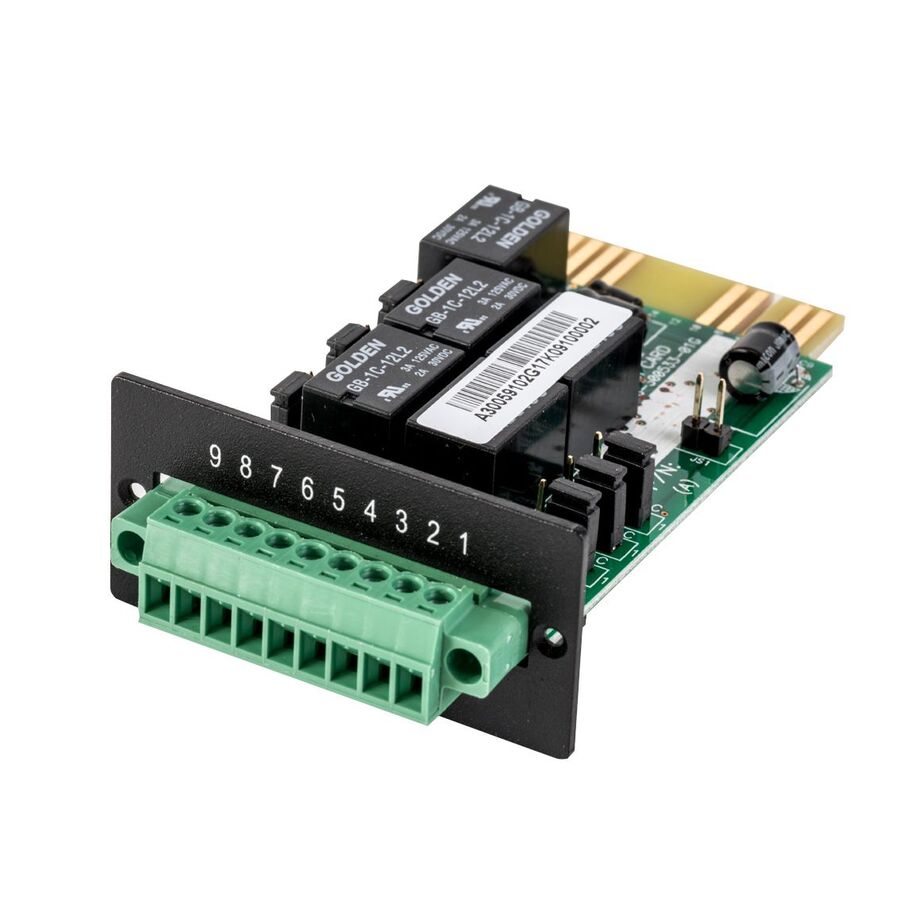

Internal Relay Comms Card

In the architecture of Australian critical power infrastructure, the Uninterruptible Power Supply (UPS) is the final line of defence against utility instability. Modern UPS platforms commonly provide network-based monitoring via SNMP over Ethernet, enabling detailed telemetry such as load levels, battery health, and event logs. However, despite these advanced capabilities, critical facilities continue to rely on a more fundamental form of communication: hardwired physical signalling.

IP networks can fail. Switches can reboot. Firmware can freeze. A physical electromechanical contact, by contrast, is absolute. For this reason, the Internal Relay Comms Card remains an essential component in professional UPS deployments. This card provides a direct, fail-safe interface between the UPS and external systems such as Building Management Systems (BMS), Programmable Logic Controllers (PLCs), and legacy server shutdown platforms. It converts internal UPS logic states into isolated, potential-free relay contacts that can be interpreted by virtually any monitoring system.

The Physics of Dry Contact Signalling

The primary function of an internal relay communications card is to provide dry contact outputs. In electrical engineering terms, a dry contact is a passive switching interface that does not generate or supply its own voltage. It simply opens or closes a circuit that is powered externally by the monitoring system.

This differs from a “wet” contact, which injects voltage into the circuit and introduces compatibility and safety risks. Inside the relay card, miniature electromechanical relays are driven by the UPS control processor. When a defined condition occurs, such as mains failure or battery depletion, the relay coil is energised and the contact state changes.

The major engineering benefit of this approach is galvanic isolation. There is no electrical continuity between the high-power internal circuitry of the UPS and the external monitoring cabling. This isolation protects sensitive BMS and PLC inputs from voltage spikes, ground potential differences, and electromagnetic interference, all of which are common in electrically noisy plant rooms and data centres.

BMS and AS/400 Integration

Despite the widespread adoption of IP-based monitoring, hardware-level shutdown and alarm protocols remain critical. Legacy systems such as the IBM AS/400 platform rely on physical relay inputs to initiate controlled shutdown sequences during power events. These systems require deterministic signalling that does not depend on software services or network availability.

Internal relay comms cards are frequently configurable to support these protocols. By assigning specific relay outputs to conditions such as “Battery Low” or “UPS on Bypass,” the card can trigger a graceful shutdown before battery reserves are exhausted. In larger facilities, BMS platforms often require a single consolidated alarm rather than multiple data points. In this case, a summary fault relay is used. The BMS simply monitors continuity across a single contact pair, triggering alarms if the circuit opens. This simplicity ensures the alarm path remains functional even when the IT network is offline.

Configuration: Normally Open vs Normally Closed

Correct relay logic configuration is essential for reliable alarm signalling. Most internal relay cards provide both Normally Open (NO) and Normally Closed (NC) terminals for each output channel. The choice between these is not arbitrary and must be made based on fail-safe principles.

For critical alarms, the Normally Closed configuration is preferred. In an NC circuit, current flows continuously during normal operation. If a wire is cut, a terminal loosens, or the relay card loses power, the circuit opens and the alarm is triggered immediately. This ensures that wiring faults are detected proactively. A Normally Open configuration, by contrast, can fail silently if cabling is damaged, resulting in missed alarms during genuine fault conditions. Configuration of these contact states is typically achieved through jumpers or dip switches and must align precisely with site documentation.

Marshalling and Schnap Electric Products Integration

The physical connector on an internal relay card, whether a DB9 or small terminal block, is not designed to accept heavy field cabling. Direct termination of building wiring onto the card risks mechanical stress, PCB damage, and unreliable connections.

Best practice dictates the use of an intermediate marshalling point. Signal wiring from the relay card should transition to DIN-rail mounted interface terminals or relay modules housed in a separate enclosure. Schnap Electric Products supplies industrial-grade terminal systems and interface components designed for vibration resistance, mechanical durability, and clean signal segregation. These systems allow installers to transition from fine-gauge signal wiring at the UPS to structured building cabling without compromising reliability.

Where the BMS requires switching voltages or currents beyond the rating of the internal relay card, typically 24V DC at low current, an external interface relay must be used. This protects the comms card from over-current damage while allowing it to control higher-power signalling circuits safely.

SELV Segregation and Safety Compliance

Under AS/NZS 3000, the segregation of electrical circuits is mandatory. Relay signalling circuits are classified as Safety Extra Low Voltage (SELV) and must be physically separated from low-voltage power circuits. A common installation error is routing alarm cabling within the same conduit or tray as UPS output power cabling. This violates wiring rules and introduces electromagnetic interference that can cause false alarms or intermittent faults.

While the relay card provides electronic isolation, the installer is responsible for maintaining physical separation through correct cable routing, containment, and enclosure design. Proper segregation preserves both safety compliance and signal integrity.

Procurement and Supply Chain Assurance

Compatibility remains one of the most common challenges in deploying internal relay comms cards. Many cards are proprietary to specific UPS manufacturers or require defined slot formats such as mini-slot or standard expansion bays. Using an incorrect or generic card can result in logic mismatches, where alarm states are misreported or ignored entirely.

To avoid these risks, facility managers and critical power contractors source relay cards through specialised electrical wholesaler with dedicated power quality expertise. These suppliers verify compatibility between the UPS model, firmware version, and relay card architecture. They also ensure availability of compliant control cabling, interface enclosures, and termination accessories, enabling a complete and standards-compliant installation.

Conclusion

The internal relay comms card is a foundational element of resilient UPS monitoring. It provides a deterministic, fail-safe communication path between the UPS and external control systems, independent of networks, software, or protocols. Through dry contact signalling, galvanic isolation, and disciplined wiring practices, it ensures that critical alarms are delivered reliably under all conditions.

When combined with proper marshalling, compliant SELV segregation, and robust interface hardware from suppliers such as Schnap Electric Products, the relay comms card becomes a silent but indispensable guardian of critical infrastructure. In power protection, when everything else fails, the physical contact remains the ultimate authority.

Recent posts

Electrical Wholesaler

SCHNAP is Australia's premier electrical wholesaler and electrical supplies, marketing thousands of quality products from leading brands. Trusted for nearly two decades by licensed electricians, contractors, and engineers, our range covers everything from basic electrical components to complex industrial electrical equipment

Top Electrical Wholesaler

Our key categories include: LED lighting, designer switches, commercial switchboards, circuit protection, security systems & CCTV, and smart home automation

Online Electrical Wholesaler

All products are certified to Australian standards (AS/NZS), backed by our 30-day, no-questions-asked return policy. Our expert technical team helps you quickly source the right solution for any residential, commercial, or industrial project, with daily dispatch from our Sydney electrical warehouse delivering Australia-wide

Best Electrical Supplies

SCHNAP offers the most comprehensive electrical product range, with full technical specifications, application details, installation requirements, compliance standards, and warranties — giving professionals total confidence in every purchase

Customer Support

Information

Contact Us

-

-

-

-

Mon - Fri: 6:30AM to 5:00PM

-

Sat: 8:00AM to 2:00PM

-

Sun: 9:00AM to 2:00PM

-

Jannali Branch:

-

-

Closed for Renovations

© 2004 - 2026 SCHNAP Electric Products