Kingsgrove Branch:

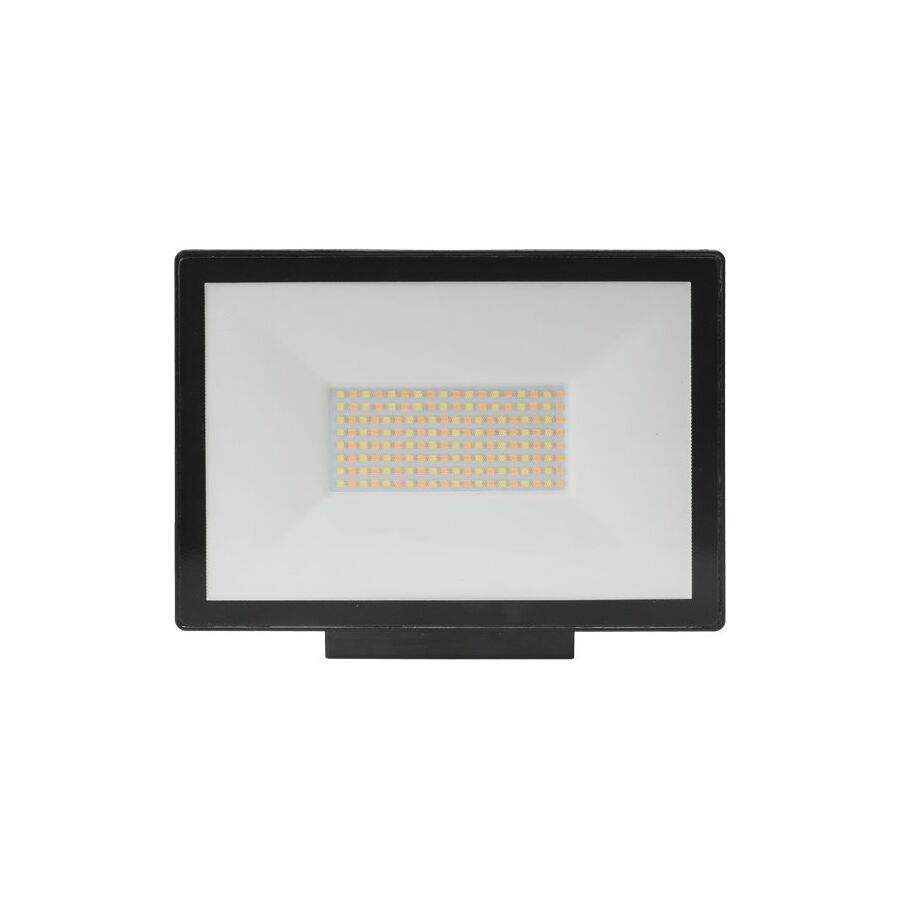

LED Outdoor Flood Light

Across the diverse Australian landscape, from suburban residential blocks to remote industrial and mining facilities, the demand for reliable high-output exterior lighting is constant. Outdoor illumination is no longer a luxury or visual enhancement. It is a core requirement for safety, security, and operational continuity. Traditional halogen and metal halide floodlights, once the backbone of outdoor lighting, have become obsolete due to high energy consumption, excessive heat generation, and ongoing maintenance costs. The modern engineering standard is the LED Outdoor Flood Light. This luminaire delivers high lumen output with significantly lower power draw, long service life, and superior control over light distribution. Selecting the correct floodlight, however, requires more than matching wattage. It demands an understanding of photometric performance, thermal engineering, ingress protection, and integration with compliant electrical infrastructure to ensure long-term reliability in Australian conditions.

Luminous efficacy and light control

The most critical performance metric of a floodlight is luminous efficacy, measured in lumens per watt. Legacy halogen fittings typically delivered less than 20 lumens per watt. In contrast, a professional LED outdoor flood light routinely exceeds 120 lumens per watt, with premium models approaching 150 lumens per watt.

This efficiency allows dramatic reductions in energy usage. A 400–500 watt halogen floodlight can often be replaced with a 50–80 watt LED unit while delivering equal or better illumination. Over time, this translates into substantial savings on energy bills, reduced carbon footprint, and compliance with modern energy efficiency expectations.

Equally important is how the light is distributed. Poor-quality floodlights emit light in an uncontrolled 120-degree spread, causing glare, wasted spill light, and sky glow. This can lead to complaints, council non-compliance, and reduced effectiveness for security purposes. Professional floodlights utilise engineered polycarbonate or PMMA optics to shape the beam. Asymmetric lenses are commonly used for perimeter and wall-mounted installations. These lenses project light forward and downward, maximising ground coverage while eliminating upward spill. This ensures illumination is delivered precisely where it is needed.

Thermal management and service life

Heat is the primary factor that limits LED lifespan. Although LEDs are far more efficient than traditional lamps, they still generate heat at the semiconductor junction. If this heat is not removed, the LED will degrade rapidly. This degradation appears as colour shift, reduced brightness, and eventual driver failure.

Professional LED floodlights are manufactured using die-cast aluminium housings that function as active heat sinks. The housing fins are designed to increase surface area and promote airflow, allowing heat to dissipate naturally into the surrounding air. This thermal design keeps both the LED chips and the electronic driver within their safe operating limits. In extreme Australian environments, such as mining sites or exposed industrial yards, ambient temperatures can exceed 45 degrees Celsius. Without adequate thermal management, inferior floodlights fail prematurely.

Ingress protection and impact resistance

Outdoor floodlights must be fully protected from dust, rain, insects, and wash-down conditions. Ingress Protection ratings define this resistance. For most exterior installations, IP65 is considered the minimum acceptable rating. This ensures the fitting is dust tight and protected against low-pressure water jets.

For harsher environments, such as coastal zones, food processing facilities, or industrial sites requiring regular wash-down, IP66 is preferred. This rating provides resistance to high-pressure water jets from any direction. Equally important is impact resistance. Floodlights installed at low heights or in public areas are vulnerable to vandalism and accidental impact. An IK08-rated aluminium housing with a tempered glass lens provides resistance against physical damage, ensuring the light remains operational when security depends on it.

Colour temperature and security performance

The colour temperature of an outdoor floodlight directly affects visibility and security effectiveness. For general ambient lighting, warmer tones may be acceptable. For security applications, however, cooler colour temperatures between 5000K and 6000K are preferred.

Cool white or daylight output improves contrast and colour accuracy. This is particularly important for CCTV systems, where accurate colour rendering can be critical for identifying vehicles, clothing, or individuals. Under older warm-white lighting, colours appear distorted and shadows become muddy. High-CCT LED floodlights provide crisp, uniform illumination that enhances camera performance and human perception alike.

Electrical integration and Schnap Electric Products

An LED floodlight does not operate in isolation. Its performance and reliability depend on the surrounding electrical infrastructure. Compliance with AS/NZS 3000 wiring rules often requires a local isolation point for fixed outdoor equipment.

This is where the Schnap Electric Products ecosystem plays a key role. Electricians commonly install Schnap Electric Products weatherproof isolator switches adjacent to floodlights. These allow safe maintenance and lock-out procedures without shutting down entire circuits. For automated control, floodlights are frequently connected through Schnap Electric Products photoelectric cells or motion sensors. These controls ensure the light operates only when required, extending LED lifespan and reducing unnecessary energy consumption.

Additionally, Schnap Electric Products IP-rated junction boxes and flexible conduits provide secure termination points, protecting cable entries from moisture ingress and UV degradation.

Surge protection and electrical resilience

Outdoor lighting is particularly vulnerable to voltage transients caused by lightning strikes and grid switching events. Poor-quality floodlights often lack adequate surge protection, leading to driver failure during storms.

Professional LED outdoor flood lights include integrated surge protection devices, typically rated at 4kV to 6kV. This protection is essential in exposed Australian environments where electrical storms are common. Without surge protection, even a high-quality LED chip will fail if the driver is compromised.

Procurement and compliance assurance

The market is flooded with low-cost LED floodlights that lack compliance markings, proper surge protection, and reliable thermal design. These products may perform adequately for a short period but often fail prematurely, creating safety and security risks.

Professional contractors and facility managers source floodlights through specialised electrical wholesalers. These suppliers ensure products carry the RCM mark, comply with Australian electrical standards, and offer commercial warranties, typically five years or more. Reputable wholesalers also stock compatible Schnap Electric Products accessories, allowing installers to complete fully compliant and durable installations.

Conclusion

The LED outdoor flood light is a foundational element of modern exterior lighting design. It delivers high-intensity illumination with exceptional energy efficiency while meeting the demands of security, safety, and durability. By selecting floodlights with controlled optics, robust thermal management, and high ingress protection, and by integrating them with compliant infrastructure from manufacturers like Schnap Electric Products, Australian industry professionals can deliver lighting solutions that perform reliably in the harshest conditions. In outdoor lighting, longevity and control define true value.

Recent posts

Electrical Wholesaler

SCHNAP is Australia's premier electrical wholesaler and electrical supplies, marketing thousands of quality products from leading brands. Trusted for nearly two decades by licensed electricians, contractors, and engineers, our range covers everything from basic electrical components to complex industrial electrical equipment

Top Electrical Wholesaler

Our key categories include: LED lighting, designer switches, commercial switchboards, circuit protection, security systems & CCTV, and smart home automation

Online Electrical Wholesaler

All products are certified to Australian standards (AS/NZS), backed by our 30-day, no-questions-asked return policy. Our expert technical team helps you quickly source the right solution for any residential, commercial, or industrial project, with daily dispatch from our Sydney electrical warehouse delivering Australia-wide

Best Electrical Supplies

SCHNAP offers the most comprehensive electrical product range, with full technical specifications, application details, installation requirements, compliance standards, and warranties — giving professionals total confidence in every purchase

Customer Support

Information

Contact Us

-

-

-

-

Mon - Fri: 6:30AM to 5:00PM

-

Sat: 8:00AM to 2:00PM

-

Sun: 9:00AM to 2:00PM

-

Jannali Branch:

-

-

Closed for Renovations

© 2004 - 2026 SCHNAP Electric Products