Kingsgrove Branch:

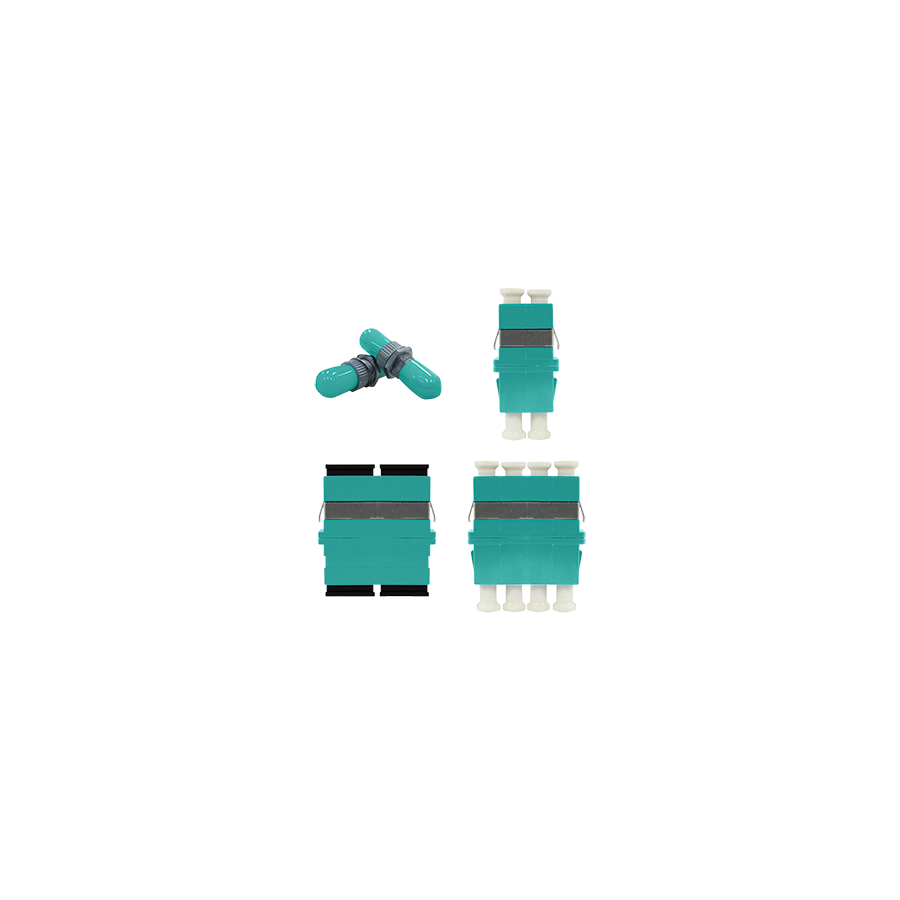

OM3 Fiber Optic Adaptors

The digital infrastructure supporting Australian commercial enterprise is evolving rapidly. As organisations adopt cloud-based platforms, high-definition video conferencing, building analytics, and data-driven operations, the bandwidth demands placed on local area networks continue to rise. While single-mode fibre dominates long-haul telecommunications, the internal backbone of most commercial environments, including vertical risers and campus links, is built on multimode fibre. In particular, OM3 has become the default standard for 10 Gigabit Ethernet deployments due to its performance, cost efficiency, and suitability for distances up to 300 metres.

Although the quality of the fibre cable itself is critical, network performance is often determined at the connection points. Patch panels, wall outlets, and cross-connect frames rely on OM3 fiber optic adaptors to join fibre links together. These adaptors are passive devices, yet they play an essential role in maintaining optical alignment, controlling signal loss, and ensuring long-term stability. Poor adaptor quality can undermine an otherwise well-designed network, making adaptor selection a critical engineering decision.

The Physics of Core Alignment

The fundamental role of a fibre optic adaptor is to align two fibre connectors so that light passes from one core to the other with minimal loss. In an OM3 system, the fibre core measures 50 microns in diameter. Even a slight offset between mating connectors can result in insertion loss that erodes the optical power budget of the link.

Insertion loss is measured in decibels and represents the reduction in signal strength caused by misalignment, air gaps, or surface imperfections. If this loss exceeds the tolerance of the network transceiver, the link may exhibit packet errors, reduced throughput, or complete failure. OM3 adaptors achieve alignment by using an internal sleeve that holds the ceramic ferrules of the connectors in precise axial alignment. This physical contact also reduces back-reflection, which can interfere with the Vertical-Cavity Surface-Emitting Lasers commonly used in multimode equipment.

Alignment Sleeve Materials and Long-Term Stability

Not all OM3 adaptors offer the same level of performance or durability. One of the most important differentiators is the material used for the internal alignment sleeve. Entry-level adaptors often use phosphor bronze sleeves, which are inexpensive and functional for low-speed applications. However, phosphor bronze is softer than the ceramic ferrules of fibre connectors and can deform over repeated insertions.

Professional-grade OM3 installations specify zirconia ceramic alignment sleeves. Zirconia is extremely hard and dimensionally stable, ensuring that alignment accuracy is maintained across hundreds of mating cycles. It is also resistant to temperature variation, which is important in rack environments where heat fluctuations are common. By maintaining consistent alignment, zirconia sleeves protect the optical budget and preserve network performance over the life of the installation.

Colour Coding and Visual Identification

In dense rack environments, visual identification is a critical safeguard against human error. Connecting the wrong type of patch lead can instantly disrupt a network segment. To address this risk, the industry follows the TIA-598-C colour coding standard.

OM3 components are universally identified by an aqua or teal colour. OM3 fiber optic adaptors use aqua housings to clearly indicate their suitability for multimode 10GbE links. This visual cue allows technicians to distinguish OM3 ports from single-mode adaptors, which are typically blue, or legacy multimode systems using beige or black. Clear colour differentiation reduces the risk of incorrect patching and speeds up installation and maintenance tasks.

Mechanical Housing and Panel Integration

An OM3 adaptor must remain mechanically stable within its mounting surface. Adaptors are typically installed into patch panels, wall plates, or fibre management trays using standard simplex or duplex footprints. If the adaptor housing does not fit securely, inserting or removing a patch cord can cause movement that stresses the rear pigtails or fusion splices.

This is where Schnap Electric Products contributes to installation integrity. Schnap Electric Products supplies fibre patch panels and Fibre Optic Break Out Trays engineered with precise cut-outs and retention clips. These enclosures hold OM3 adaptors firmly in place, preventing rearward movement during patching and protecting the delicate fibre terminations behind the panel. Secure housing is essential to maintaining bend radius compliance and avoiding long-term micro-damage to fibres.

Connector Formats: LC and SC

OM3 fiber optic adaptors are most commonly supplied in LC and SC formats. SC connectors are larger and use a push-pull design, making them robust and easy to handle. They are often found in legacy systems, media converters, and industrial equipment.

LC connectors are smaller and designed for high-density environments. An LC duplex adaptor combines two simplex channels into a single footprint, supporting transmit and receive fibres in one compact unit. This format allows significantly higher port density within a standard rack, making it the preferred choice for modern data centres and enterprise networks where space efficiency is critical.

Cleanliness and Optical Performance

Even the highest-quality adaptor cannot compensate for contamination. Dust, oil, or residue on connector end-faces is one of the leading causes of optical loss and network instability. When connectors are mated through an adaptor, any contamination can be transferred and amplified across multiple patching cycles.

Professional installation standards require a strict “inspect, clean, connect” process. Adaptors should be installed in clean environments, and connectors must be cleaned before insertion. Maintaining cleanliness protects the alignment sleeve, preserves ferrule surfaces, and ensures consistent optical performance.

Procurement and Quality Assurance

The performance of an OM3 adaptor is influenced by manufacturing precision that is not visible to the naked eye. Poor concentricity, weak retention clips, or brittle plastics can compromise alignment and durability. In commercial projects, adaptor failure can impact dozens of services simultaneously.

For this reason, data cablers and system integrators source OM3 fiber optic adaptors through specialised electrical wholesaler with communications expertise. These suppliers verify compliance with Australian Standards such as AS/NZS 3080 and ensure that adaptors meet requirements for alignment accuracy, insertion force, and mechanical stability. They also provide compatible patch panels, cleaning tools, and accessories, allowing the physical layer to be deployed as a cohesive system rather than a mix of unverified components.

Conclusion

OM3 fiber optic adaptors may be small components, but they are critical to the success of high-speed multimode networks. By ensuring precise core alignment, minimising insertion loss, and maintaining stable mechanical support, they protect the optical budget and enable reliable 10 Gigabit Ethernet performance. When specified with zirconia ceramic sleeves, clearly identified through aqua colour coding, and integrated into robust infrastructure from suppliers such as Schnap Electric Products, OM3 adaptors help Australian businesses build networks that are resilient, scalable, and future-ready. In fibre networking, accuracy at the interface defines performance across the entire link.

Recent posts

Electrical Wholesaler

SCHNAP is Australia's premier electrical wholesaler and electrical supplies, marketing thousands of quality products from leading brands. Trusted for nearly two decades by licensed electricians, contractors, and engineers, our range covers everything from basic electrical components to complex industrial electrical equipment

Top Electrical Wholesaler

Our key categories include: LED lighting, designer switches, commercial switchboards, circuit protection, security systems & CCTV, and smart home automation

Online Electrical Wholesaler

All products are certified to Australian standards (AS/NZS), backed by our 30-day, no-questions-asked return policy. Our expert technical team helps you quickly source the right solution for any residential, commercial, or industrial project, with daily dispatch from our Sydney electrical warehouse delivering Australia-wide

Best Electrical Supplies

SCHNAP offers the most comprehensive electrical product range, with full technical specifications, application details, installation requirements, compliance standards, and warranties — giving professionals total confidence in every purchase

Customer Support

Information

Contact Us

-

-

-

-

Mon - Fri: 6:30AM to 5:00PM

-

Sat: 8:00AM to 2:00PM

-

Sun: 9:00AM to 2:00PM

-

Jannali Branch:

-

-

Closed for Renovations

© 2004 - 2026 SCHNAP Electric Products