Kingsgrove Branch:

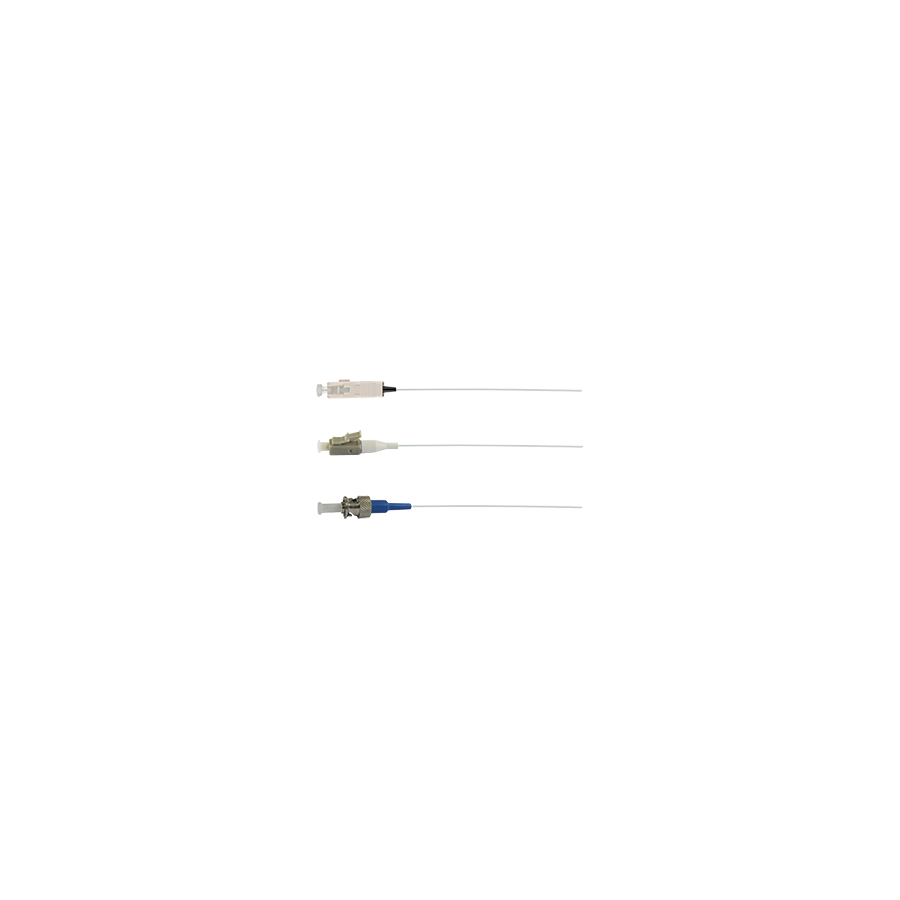

OM3 Fiber Pigtails

In the demanding environment of Australian structured cabling and data centre operations, the integrity of the physical layer underpins all network performance. As enterprises adopt bandwidth-intensive services such as cloud platforms, real-time analytics, and high-definition video surveillance, 10 Gigabit Ethernet has become the minimum expectation for commercial backbones. While backbone fibre cables provide long-distance connectivity, the way those fibres are terminated at the rack ultimately determines whether the network performs as designed.

Historically, field-installed connectors were common, with technicians polishing connectors onsite. While workable, this approach introduces significant variability in end-face geometry, cleanliness, and insertion loss. The modern engineering standard has shifted decisively toward fusion splicing using OM3 fiber pigtails. These factory-terminated components provide a controlled, repeatable interface between external fibre cables and active equipment, ensuring consistent optical performance and long-term reliability.

The Physics of Factory-Polished Connectors

The primary advantage of an OM3 fiber pigtail lies in the quality of its connector end-face. A pigtail consists of a short length of fibre, typically one to two metres, with a connector pre-installed and polished in a controlled factory environment. Automated polishing machines produce precise Ultra Physical Contact profiles, achieving very low insertion loss, commonly below 0.3dB, and high return loss that minimises back-reflection.

Achieving this level of precision in the field is extremely difficult due to dust, vibration, and manual variability. By fusion splicing a factory-polished pigtail to the incoming cable, the installer removes the connector interface as a performance risk. The only remaining variable is the fusion splice itself, which typically contributes less than 0.02dB of loss when performed correctly. This approach ensures compliance with IEC and Australian standards while significantly improving installation consistency.

OM3 Fibre Specifications and VCSEL Compatibility

OM3 fibre is a laser-optimised multimode standard with a 50-micron core and 125-micron cladding. It is specifically designed for use with Vertical-Cavity Surface-Emitting Lasers operating at 850nm, which are standard in 10GbE and 40GbE transceivers. OM3 fibre supports 10GbE transmission distances of up to 300 metres, making it ideal for campus backbones and data centre cross-connects.

OM3 fiber pigtails must match the glass geometry of the backbone cable exactly. Any mismatch, such as splicing a 62.5-micron OM1 pigtail onto an OM3 cable, results in severe core misalignment and unacceptable signal loss. The distinctive aqua jacket used on OM3 pigtails provides an immediate visual cue, helping technicians avoid accidental cross-connection with single-mode or legacy multimode systems.

Buffer Design and Splice Preparation

Unlike patch cords, OM3 fiber pigtails are designed specifically for fusion splicing. They typically use a 900-micron tight buffer rather than a heavy outer jacket. This buffer protects the 250-micron primary coating while remaining flexible and easy to handle inside splice trays.

Professional-grade pigtails feature easy-strip buffers that allow technicians to remove long sections cleanly without damaging the glass. This is critical during fusion splicing, where clean, undamaged fibre ends are required to achieve a low-loss splice. Poor buffer design increases the risk of micro-cracks or contamination, which can compromise long-term performance even if the splice initially tests within limits.

Colour Coding and Fibre Management

As fibre counts increase, clear identification becomes essential. High-density cables entering a rack can quickly become unmanageable without strict organisation. The industry follows the TIA-598-C colour coding standard, which defines a consistent 12-colour sequence for fibre identification.

OM3 fiber pigtails are supplied in colour-coded sets following this standard, allowing each pigtail to be matched directly to the corresponding fibre strand in the incoming cable. By maintaining colour continuity from the backbone through to the patch panel, technicians ensure traceability throughout the network. This simplifies commissioning, fault finding, and future upgrades, reducing the risk of accidental service disruption.

FOBOT Integration and Mechanical Protection

The fusion splice between a pigtail and a backbone cable is mechanically fragile and must be protected. This protection is provided by heat-shrink splice sleeves housed within a splice cassette, which in turn is mounted inside a Fibre Optic Break Out Tray.

This is where Schnap Electric Products plays an important role in installation quality. Schnap Electric Products supplies fibre management trays and 19-inch rack enclosures engineered to accommodate standard splice cassettes and maintain correct bend radii. Internal routing guides and retention clips prevent the 900-micron pigtails from being pinched, overstressed, or disturbed during maintenance, preserving splice integrity over the life of the installation.

Procurement and Quality Assurance

The optical quality of a pigtail cannot be judged visually. Core concentricity, ferrule geometry, and polish quality all affect performance but require specialised testing to verify. Low-quality pigtails may introduce excessive loss even when spliced correctly, undermining the entire link.

Forliable installations depend on sourcing components through specialised electrical wholesaler with strong data and communications expertise. These suppliers ensure that OM3 fiber pigtails meet geometry and loss specifications before distribution and provide access to compatible splice protectors, cleaning materials, and fibre management hardware. This integrated supply approach reduces risk and ensures compliance with Australian cabling standards.

Conclusion

OM3 fiber pigtails are a critical yet often overlooked element of high-speed multimode networks. They provide a reliable, factory-polished interface that transforms raw fibre cables into stable, standards-compliant connections. By using fusion splicing, adhering to colour-coding discipline, and housing terminations within robust infrastructure from suppliers such as Schnap Electric Products, Australian network professionals can deliver data cabling systems that are consistent, scalable, and ready for future demand. In optical networking, performance is defined at the termination point, and OM3 fiber pigtails ensure that definition is precise.

Recent posts

Electrical Wholesaler

SCHNAP is Australia's premier electrical wholesaler and electrical supplies, marketing thousands of quality products from leading brands. Trusted for nearly two decades by licensed electricians, contractors, and engineers, our range covers everything from basic electrical components to complex industrial electrical equipment

Top Electrical Wholesaler

Our key categories include: LED lighting, designer switches, commercial switchboards, circuit protection, security systems & CCTV, and smart home automation

Online Electrical Wholesaler

All products are certified to Australian standards (AS/NZS), backed by our 30-day, no-questions-asked return policy. Our expert technical team helps you quickly source the right solution for any residential, commercial, or industrial project, with daily dispatch from our Sydney electrical warehouse delivering Australia-wide

Best Electrical Supplies

SCHNAP offers the most comprehensive electrical product range, with full technical specifications, application details, installation requirements, compliance standards, and warranties — giving professionals total confidence in every purchase

Customer Support

Information

Contact Us

-

-

-

-

Mon - Fri: 6:30AM to 5:00PM

-

Sat: 8:00AM to 2:00PM

-

Sun: 9:00AM to 2:00PM

-

Jannali Branch:

-

-

Closed for Renovations

© 2004 - 2026 SCHNAP Electric Products