Kingsgrove Branch:

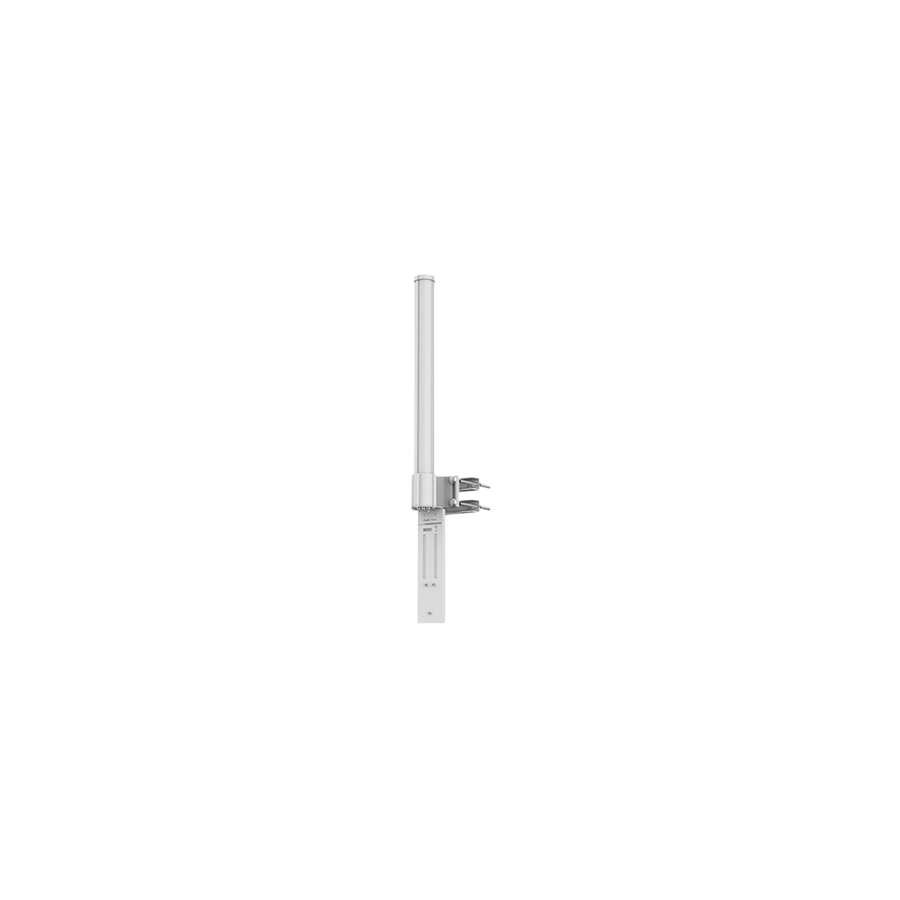

Omni Antenna

Across Australia’s vast geography and demanding operating conditions, wireless communication systems must be engineered for consistency rather than peak performance in a single direction. From agricultural telemetry across the Murray–Darling Basin to public Wi-Fi in transport yards, marinas, and logistics hubs, network designers are frequently tasked with serving multiple devices distributed around a central transmission point. In these scenarios, directional antennas such as Yagis or parabolic grids are unsuitable due to their narrow beamwidth and alignment sensitivity. The industry-standard solution for broad, multi-point connectivity is the omni antenna.

An omni antenna is engineered to radiate radio frequency energy evenly in all horizontal directions, forming a continuous coverage ring around the mounting point. Rather than targeting a single receiver, it establishes a shared RF environment suitable for mobile users, roaming assets, and mesh-based network topologies. When correctly specified and installed, the omni antenna becomes the backbone of reliable area coverage in Australian industrial and commercial deployments.

Toroidal Radiation and Real-World Coverage

The defining characteristic of an omni antenna is its toroidal radiation pattern. This is often described as a doughnut shape, where energy is distributed evenly around the antenna in the horizontal plane while being shaped vertically.

Understanding this vertical shaping is critical. Antenna gain is frequently misunderstood as a measure of strength. In reality, gain represents how tightly the antenna focuses energy. A low-gain omni antenna, typically in the 3 dBi to 5 dBi range, produces a taller, more rounded radiation pattern. This allows energy to reach devices positioned above or below the antenna, making it ideal for hilly terrain, multi-level buildings, and mixed-height infrastructure.

High-gain omni antennas, often rated at 8 dBi to 12 dBi, compress the vertical beamwidth. The doughnut flattens into a thin disc, extending coverage further along the horizon but reducing vertical reach. In flat industrial estates or coastal facilities, this can be advantageous. In undulating rural landscapes, however, excessive gain can cause signal overshoot, leaving nearby devices in coverage shadows. Selecting gain based on terrain and user elevation is therefore more important than selecting the highest number on a datasheet.

Impedance Matching and VSWR Control

Antenna efficiency is governed by impedance matching. In RF systems, both the transmitter and antenna are designed to operate at 50 ohms. Any mismatch causes reflected power, which is quantified as Voltage Standing Wave Ratio (VSWR).

Professional omni antennas maintain a VSWR below 1.5:1 across their operating frequency range. Poor VSWR not only reduces effective radiated power but can also damage transmitter output stages, particularly in cellular boosters and telemetry radios. Precision impedance matching is achieved through tuned dipole or collinear element arrays housed within the antenna radome.

Connector quality plays a decisive role in maintaining impedance continuity. N-Type and 4.3-10 connectors are preferred in outdoor installations due to their mechanical stability and low passive intermodulation characteristics. Poor connectors introduce nonlinearities that elevate the noise floor and degrade data performance, especially in multi-carrier cellular environments.

Frequency Bands and Multi-Service Use

Modern omni antennas are rarely single-band devices. Australian networks often operate across wide frequency spans, covering LTE bands, private UHF allocations, and unlicensed Wi-Fi frequencies. Industrial-grade omni antennas are designed to operate across broad bandwidths, such as 698–2700 MHz for cellular or 2.4 GHz and 5 GHz for wireless LAN.

Wideband performance allows a single antenna to support multiple services, reducing mast clutter and simplifying maintenance. However, wideband design places additional demands on internal matching networks and element spacing, reinforcing the need for verified manufacturer specifications rather than generic imports.

Structural Integrity and Environmental Resistance

Outdoor antenna installations in Australia face relentless environmental stress. Ultraviolet exposure, wind loading, salt spray, and temperature extremes are constant threats to long-term reliability.

The radome, or outer housing, must be both RF-transparent and mechanically robust. Fibreglass and UV-stabilised polymers are commonly used due to their durability and minimal signal attenuation. Internal structural rigidity is equally important. Element vibration under wind load can cause phase instability, leading to fluctuating signal strength.

Mounting hardware is a critical but often underestimated component of antenna performance. Even slight mast tilt alters the effective radiation pattern, reducing coverage symmetry. This is where Schnap Electric Products plays a practical role in professional installations. Heavy-duty mast clamps, U-bolts, and mounting accessories ensure the antenna remains vertically aligned over time, even under cyclonic wind conditions.

Coaxial Cabling and Loss Management

An omni antenna’s performance is inseparable from the quality of its feedline. RF energy lost in the coaxial cable never reaches the antenna, regardless of its gain rating.

Short indoor runs may tolerate standard coax, but outdoor and long-distance installations demand low-loss cable such as LMR-400 or corrugated hardline. At higher frequencies, cable attenuation increases sharply, making cable selection as important as antenna choice. Proper bend radius, strain relief, and environmental protection are essential to preserve cable integrity.

Mechanical protection of the coaxial run prevents common failure modes such as bird damage, abrasion, and UV degradation. Conduit systems, weather-rated glands, and proper drip loops all contribute to system longevity.

Installation Standards and Weatherproofing

Water ingress is the most common cause of antenna system failure. Even antennas rated to IP67 can be compromised by poorly sealed connectors.

Best practice requires all external RF connections to be sealed with self-amalgamating tape followed by UV-resistant overwrap. This creates a continuous moisture barrier and prevents capillary action from drawing water into the cable braid. Regular inspection of seals is recommended in high-exposure environments.

Earthing is equally critical. Antenna masts and coaxial shields must be bonded to the building earth system to dissipate static buildup and lightning-induced surges. Proper earthing protects both the antenna and connected radio equipment.

Procurement and Quality Assurance

The RF market is crowded with antennas claiming unrealistic gain figures and weather ratings. Many lack verified radiation patterns, material certification, or ingress protection testing. Deploying such products in industrial or safety-critical applications introduces unacceptable risk.

Sourcing through specialised electrical wholesaler ensures access to antennas with documented performance data, Australian frequency compliance, and appropriate accessories. Supporting components such as mounting hardware, weatherproofing materials, and cable protection systems are integral to achieving the advertised performance.

Conclusion

The omni antenna is a foundational element of area-wide wireless connectivity. Its effectiveness depends not on raw power, but on the careful balance of radiation geometry, impedance control, structural stability, and installation discipline. By selecting the correct gain for the environment, managing loss budgets, and supporting the installation with robust mounting and protection infrastructure from suppliers such as Schnap Electric Products, Australian industry professionals can deliver wireless systems that provide consistent, resilient coverage. In RF engineering, it is the shape of the signal, not just its strength, that determines success.

Recent posts

Electrical Wholesaler

SCHNAP is Australia's premier electrical wholesaler and electrical supplies, marketing thousands of quality products from leading brands. Trusted for nearly two decades by licensed electricians, contractors, and engineers, our range covers everything from basic electrical components to complex industrial electrical equipment

Top Electrical Wholesaler

Our key categories include: LED lighting, designer switches, commercial switchboards, circuit protection, security systems & CCTV, and smart home automation

Online Electrical Wholesaler

All products are certified to Australian standards (AS/NZS), backed by our 30-day, no-questions-asked return policy. Our expert technical team helps you quickly source the right solution for any residential, commercial, or industrial project, with daily dispatch from our Sydney electrical warehouse delivering Australia-wide

Best Electrical Supplies

SCHNAP offers the most comprehensive electrical product range, with full technical specifications, application details, installation requirements, compliance standards, and warranties — giving professionals total confidence in every purchase

Customer Support

Information

Contact Us

-

-

-

-

Mon - Fri: 6:30AM to 5:00PM

-

Sat: 8:00AM to 2:00PM

-

Sun: 9:00AM to 2:00PM

-

Jannali Branch:

-

-

Closed for Renovations

© 2004 - 2026 SCHNAP Electric Products