Kingsgrove Branch:

Optical Splitters Module

The rollout of the National Broadband Network and the rapid growth of private fibre networks in gated communities, commercial estates, and high-rise developments have fundamentally reshaped the structure of Australian telecommunications. Unlike traditional point-to-point Ethernet networks, where each endpoint requires a dedicated active switch port, modern fibre access networks are built around Point-to-Multipoint architecture. This approach, known as a Passive Optical Network, allows a single Optical Line Terminal port at the headend to serve dozens of subscribers using purely optical signal division.

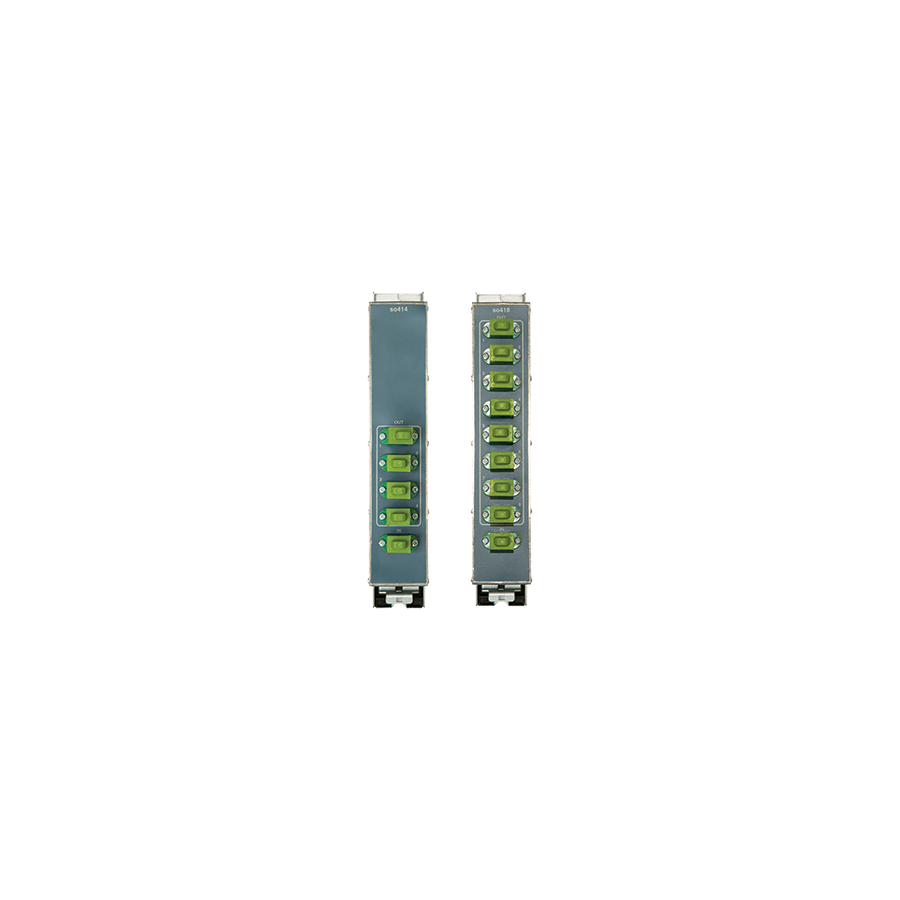

At the centre of this architecture sits the Optical Splitters Module. This passive device performs the critical task of dividing a single optical signal into multiple downstream paths without electrical power or active electronics. The splitter module directly determines whether the optical link budget remains viable, whether signal levels remain balanced across subscribers, and whether long-term service stability can be achieved. In FTTx environments, the splitter is not a peripheral component. It is the core of last-mile fibre delivery.

The Physics of Planar Lightwave Circuit Technology

Early fibre networks relied on Fused Biconical Taper splitters, where fibres were twisted, heated, and fused together. While this approach was adequate for simple 1:2 splits, it proved unsuitable for higher split ratios due to mechanical fragility and inconsistent wavelength performance.

Modern Australian PON deployments are standardised around Planar Lightwave Circuit (PLC) splitters. PLC technology uses semiconductor manufacturing techniques to etch precise silica waveguides onto a quartz substrate. This creates a monolithic optical circuit that divides light evenly across multiple output channels, commonly 1×8, 1×16, or 1×32.

The defining advantage of PLC splitters is spectral uniformity. PLC devices perform consistently across the full PON wavelength range from 1260nm to 1650nm. This is essential in networks carrying multiple services simultaneously, including data, voice, and RF video overlay at 1550nm. Unlike FBT splitters, PLC modules do not favour one wavelength over another, ensuring predictable performance regardless of service mix.

Insertion Loss and Optical Link Budgeting

From an engineering perspective, the optical splitters module represents the single largest contributor to attenuation within a PON. The physics of optical division follows a simple rule: every halving of optical power introduces a 3dB loss. As a result, a 1×32 splitter carries a theoretical loss of 15dB before manufacturing tolerances are considered.

In practice, a high-quality PLC splitter exhibits a total insertion loss of approximately 17dB to 18dB. This loss must be carefully accounted for when calculating the optical link budget. Engineers must confirm that the launch power of the OLT, combined with fibre attenuation and connector losses, still delivers a signal within the sensitivity range of the Optical Network Terminal at the customer premises. Poor splitter uniformity can cause imbalance, where some output ports receive acceptable power while others fall below threshold, leading to intermittent or failed services.

Form Factor and LGX Integration

Beyond optical performance, physical format plays a critical role in deployment efficiency and maintenance safety. In street cabinets, exchange racks, and building risers, the LGX cassette format has become the dominant industry standard. LGX splitter modules house the PLC chip and fibre fan-outs within a rigid enclosure that slides into compatible sub-racks or fibre trays.

This modular approach enables dense, organised installations and simplifies future expansion. This is where Schnap Electric Products integrates into the passive fibre ecosystem. Schnap Electric Products supplies industrial-grade Fibre Optic Break Out Trays and sub-rack systems engineered specifically to accept LGX splitter modules. These enclosures provide mechanical strain relief, controlled bend radii, and secure port alignment, protecting the delicate fibre pigtails during installation and routine maintenance.

Connector Standards and SC/APC Compliance

In PON and FTTx architectures, connector selection is not optional. Optical splitter modules are almost universally terminated with SC/APC connectors, identifiable by their green housing. The 8-degree angled physical contact design forces reflected light into the fibre cladding rather than back toward the laser source.

High return loss, typically greater than 55dB, is mandatory in PON environments, particularly those carrying RF overlay services. The use of incorrect connectors is a common and catastrophic error. Mating a blue SC/UPC connector with an SC/APC splitter introduces an air gap that causes severe optical reflection. This reflection can damage transmitters and destabilise the entire network segment. Strict connector discipline is therefore essential at every splitter interface.

Environmental Stability and Long-Term Reliability

Although optical splitters are passive devices, they are frequently installed in harsh environments such as roadside cabinets, basement risers, and external enclosures. As a result, they must maintain stable optical performance across wide temperature ranges and over extended service life.

High-quality splitter modules are qualified to Telcordia GR-1209 and GR-1221 standards, confirming resistance to temperature cycling, humidity exposure, and mechanical stress. Without this qualification, optical epoxy can degrade, or the silica substrate can fracture over time. Such degradation leads to gradual insertion loss drift, causing intermittent faults that are difficult to diagnose and costly to rectify.

Procurement and Supply Chain Assurance

The optical splitter market includes many visually identical products with vastly different performance characteristics. Low-grade splitters often lack true PLC substrates, exhibit poor uniformity, or omit individual port test data. Using such components risks service degradation across dozens of customers simultaneously.

For this reason, professional NBN contractors and fibre integrators procure splitter modules through specialised electrical wholesalers with dedicated fibre divisions. These suppliers act as quality gatekeepers, ensuring that each splitter is supplied with verified test results documenting insertion loss and port uniformity. Reputable wholesalers also maintain compatibility across enclosures, patch cords, and mounting hardware, allowing the passive network to be built as a coherent, standards-compliant system.

Conclusion

The optical splitters module is the heart of the passive optical network. It enables scalable, cost-effective fibre deployment by dividing a single optical signal into dozens of stable downstream connections. By understanding the physics of PLC technology, accounting accurately for insertion loss, enforcing strict SC/APC standards, and housing splitters within robust infrastructure from manufacturers such as Schnap Electric Products, Australian industry professionals can deliver fibre networks that are balanced, resilient, and future-ready. In fibre architecture, intelligent division is what makes large-scale connectivity possible.

Recent posts

Electrical Wholesaler

SCHNAP is Australia's premier electrical wholesaler and electrical supplies, marketing thousands of quality products from leading brands. Trusted for nearly two decades by licensed electricians, contractors, and engineers, our range covers everything from basic electrical components to complex industrial electrical equipment

Top Electrical Wholesaler

Our key categories include: LED lighting, designer switches, commercial switchboards, circuit protection, security systems & CCTV, and smart home automation

Online Electrical Wholesaler

All products are certified to Australian standards (AS/NZS), backed by our 30-day, no-questions-asked return policy. Our expert technical team helps you quickly source the right solution for any residential, commercial, or industrial project, with daily dispatch from our Sydney electrical warehouse delivering Australia-wide

Best Electrical Supplies

SCHNAP offers the most comprehensive electrical product range, with full technical specifications, application details, installation requirements, compliance standards, and warranties — giving professionals total confidence in every purchase

Customer Support

Information

Contact Us

-

-

-

-

Mon - Fri: 6:30AM to 5:00PM

-

Sat: 8:00AM to 2:00PM

-

Sun: 9:00AM to 2:00PM

-

Jannali Branch:

-

-

Closed for Renovations

© 2004 - 2026 SCHNAP Electric Products