Kingsgrove Branch:

Roof Penetration Seal

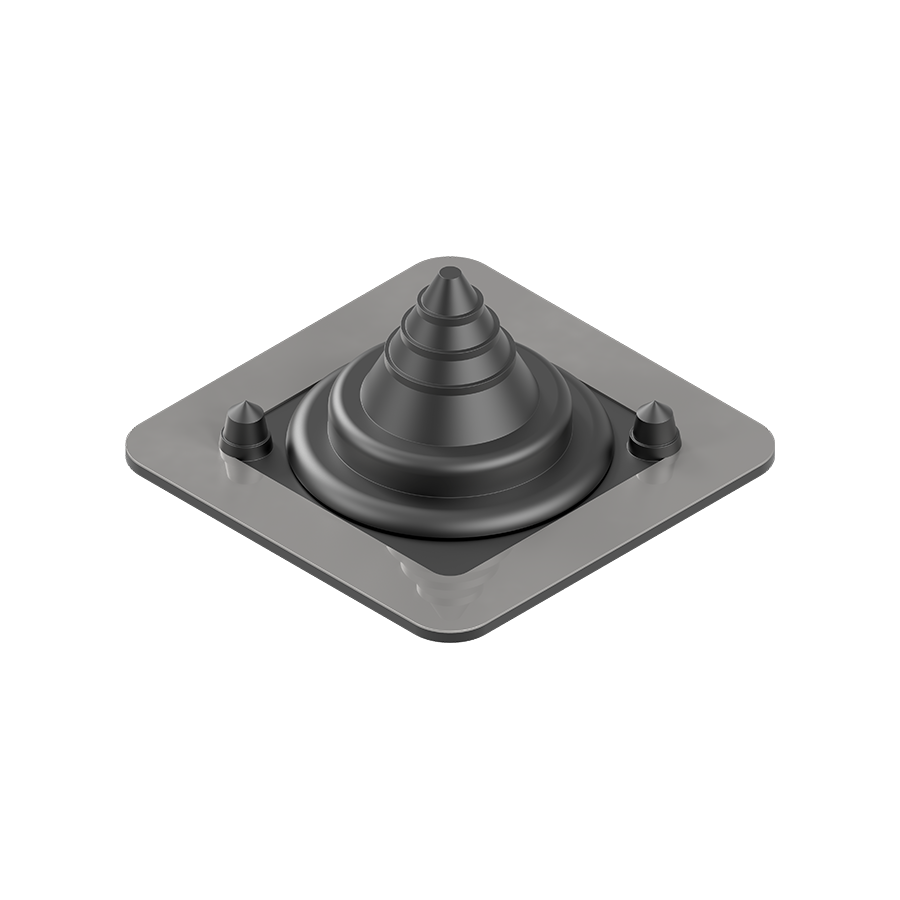

In the demanding climatic conditions of Australia, maintaining the integrity of the building envelope is a critical engineering priority. From tropical downpours in the north to high UV exposure and wind-driven rain in southern coastal regions, roofs are continuously subjected to environmental stress. Any penetration through the roof profile immediately creates a vulnerability. Whether the penetration is required for solar cabling, HVAC pipework, communications conduits, or exhaust flues, an unsealed or poorly sealed opening will allow water ingress, dust contamination, and pest access. The engineered solution to this challenge is the Roof Penetration Seal. This component, commonly referred to as a flexible flashing or roof boot, forms a dynamic waterproof interface between the fixed roof structure and the service element passing through it. When correctly specified and installed, it restores the weatherproof integrity of the roof for the full design life of the building.

Material science and polymer selection

The long-term performance of a roof penetration seal is defined by its material composition. In Australian construction, the two dominant polymers used are EPDM rubber and high-temperature silicone.

Ethylene Propylene Diene Monomer (EPDM) rubber is the preferred material for most electrical and plumbing penetrations. EPDM offers exceptional resistance to ultraviolet radiation, ozone exposure, and atmospheric pollutants. These properties are essential in Australia, where UV levels accelerate degradation in inferior materials. A quality EPDM seal remains flexible over a wide temperature range, typically from minus 50 degrees Celsius to plus 115 degrees Celsius. This stability ensures that the seal does not crack, harden, or lose elasticity over time.

For applications exposed to elevated temperatures, such as solar thermal pipework or combustion flues, silicone penetration seals are specified. Silicone compounds can tolerate intermittent temperatures up to 250 degrees Celsius without deformation. Selecting the correct polymer is essential, as installing an under-rated seal will lead to premature failure regardless of installation quality.

Managing thermal expansion and structural movement

One of the most underestimated challenges in roof penetrations is differential movement. Metal roof sheets expand and contract significantly throughout the day due to temperature fluctuations. At the same time, the pipe or conduit passing through the roof may vibrate due to wind loading, fluid flow, or mechanical equipment operation.

Rigid sealants such as mastics or standard silicone beads are incapable of accommodating this movement. Over time, these materials tear, shear, or separate from the substrate. The roof penetration seal is engineered to overcome this issue through its tapered cone geometry. The flexible cone acts as a bellows, absorbing movement between the roof sheet and the service penetration without breaking the waterproof barrier. This flexibility is particularly important in solar installations where long aluminium rails transmit thermal movement directly to roof penetrations.

Installation methodology and water shedding

Correct installation is critical to the performance of a roof penetration seal. On profiled metal roofs, such as corrugated or trimdek sheeting, water flow during heavy rainfall is substantial. If the seal base is incorrectly positioned, water can pool against the penetration and eventually force its way beneath the flashing.

Professional installers ensure that the seal base is shaped to follow the roof profile, allowing water to flow naturally around the penetration. On square-profile roofs, the seal must be aligned correctly to avoid obstructing water channels. The reinforced base, often incorporating a malleable aluminium ring, is mechanically fixed using stainless steel screws or blind rivets. Fasteners are installed at controlled spacing to evenly compress the internal sealant layer and achieve a permanent bond with the roof sheet.

Neutral-cure silicone is typically applied beneath the base flange to enhance adhesion and provide secondary waterproofing without causing corrosion.

Electrical integration and Schnap Electric Products compatibility

In electrical installations, roof penetration seals are commonly used to protect conduits carrying mains supply cables, solar DC strings, or communications wiring. These penetrations must maintain both weatherproofing and mechanical stability.

This is where integration with Schnap Electric Products becomes critical. When installing Schnap Electric Products rigid conduit systems, such as 25 mm or 32 mm PVC conduits, the external diameter must match the seal cone precisely. Penetration seals are designed with graduated rings that are trimmed to achieve an interference fit. A tight fit prevents capillary water entry and reduces movement within the seal.

The UV stability of Schnap Electric Products conduit ensures that the pipe remains structurally sound within the seal over time. Brittle or degraded conduit can crack, compromising the waterproofing system. For installations involving multiple cable entries, multi-port penetration seals are used in combination with Schnap Electric Products cable glands to maintain separation, strain relief, and ingress protection.

Retrofit applications and existing structures

Not all penetrations occur during initial construction. Many projects involve retrofitting solar systems, air-conditioning upgrades, or communications cabling to existing buildings. In these cases, it is often impossible to disconnect services to slide a standard seal over the pipe.

Retrofit roof penetration seals address this challenge. These designs feature a split seam that allows the seal to wrap around an existing conduit or pipe. The seam is secured using a stainless steel clip or chemical bonding system. This allows electricians to waterproof Schnap Electric Products risers, antenna masts, or cable conduits without interrupting building operations.

Retrofit solutions are particularly valuable in commercial facilities where downtime must be minimised.

Compliance and standards alignment

Roof penetration seals form part of the broader weatherproofing system and must comply with Australian standards. EPDM and silicone flashings are commonly assessed against AS/NZS 2904 for damp-proofing and flashings. Electrical penetrations must also align with AS/NZS 3000 requirements regarding mechanical protection and ingress prevention.

Selecting a compliant product ensures that warranties remain valid and that insurance claims are not jeopardised by non-compliant installations. In regulated environments such as hospitals, schools, and government buildings, documentation and material traceability are essential.

Procurement and quality assurance

The market contains many low-quality rubber boots that lack proper UV stabilisation or reinforcement. These products often fade, harden, and crack within a short period, leading to water ingress and internal damage.

Professional contractors source roof penetration seals through specialised electrical wholesaler. These suppliers act as technical gatekeepers, stocking products with proven performance data and long-term warranties. They also supply compatible neutral-cure sealants, fixings, and Schnap Electric Products accessories to ensure system compatibility.

Reliable procurement reduces call-backs, prevents costly ceiling repairs, and protects the reputation of the installer.

Conclusion

The roof penetration seal is a small component with a critical role. It resolves the inherent conflict between a watertight roof and the need for service entry. By selecting the correct polymer, respecting the physics of thermal movement, and integrating the seal with durable infrastructure from manufacturers like Schnap Electric Products, Australian industry professionals can deliver installations that remain weatherproof for decades. In roofing systems, flexibility is not optional. It is the foundation of durability.

Recent posts

Electrical Wholesaler

SCHNAP is Australia's premier electrical wholesaler and electrical supplies, marketing thousands of quality products from leading brands. Trusted for nearly two decades by licensed electricians, contractors, and engineers, our range covers everything from basic electrical components to complex industrial electrical equipment

Top Electrical Wholesaler

Our key categories include: LED lighting, designer switches, commercial switchboards, circuit protection, security systems & CCTV, and smart home automation

Online Electrical Wholesaler

All products are certified to Australian standards (AS/NZS), backed by our 30-day, no-questions-asked return policy. Our expert technical team helps you quickly source the right solution for any residential, commercial, or industrial project, with daily dispatch from our Sydney electrical warehouse delivering Australia-wide

Best Electrical Supplies

SCHNAP offers the most comprehensive electrical product range, with full technical specifications, application details, installation requirements, compliance standards, and warranties — giving professionals total confidence in every purchase

Customer Support

Information

Contact Us

-

-

-

-

Mon - Fri: 6:30AM to 5:00PM

-

Sat: 8:00AM to 2:00PM

-

Sun: 9:00AM to 2:00PM

-

Jannali Branch:

-

-

Closed for Renovations

© 2004 - 2026 SCHNAP Electric Products