Kingsgrove Branch:

Run On Timer

In the architectural and services-engineering context of the Australian building industry, the control of indoor air quality and latent moisture is not optional. It is a core requirement of durability, occupant health, and regulatory compliance. From coastal Queensland, where humidity is persistent year-round, to southern climates where condensation forms rapidly on cold surfaces, unmanaged moisture is one of the most destructive forces acting on residential and commercial buildings.

Bathrooms, laundries, internal powder rooms, and amenity spaces are the highest-risk zones. These areas generate bursts of water vapour that far exceed the natural drying capacity of the building envelope. The National Construction Code (NCC) and associated Australian Standards require mechanical ventilation to achieve minimum air change rates specifically to prevent mould growth, timber decay, corrosion, and degradation of plasterboard linings.

While exhaust fans are the mechanical solution, human behaviour remains the weak link. Occupants rarely leave a fan running long enough after showering for moisture to be fully evacuated. The engineering control that removes this uncertainty is the run on timer. This device ensures that ventilation continues automatically after the room is vacated, completing the drying cycle regardless of user behaviour.

Latent Humidity, Condensation, and Dwell Time Physics

The necessity of a run on timer is grounded in basic thermodynamics. During shower use, relative humidity in a bathroom rapidly approaches saturation. Water vapour remains suspended in the air even after the visible steam appears to dissipate. If ventilation stops at this point, the moisture has not been removed; it has only been redistributed.

As surfaces cool, especially ceilings, mirrors, tiles, and external walls, this vapour condenses into liquid water. Repeated condensation cycles create an ideal environment for fungal growth, particularly mould species that thrive on gypsum paper linings and silicone sealants.

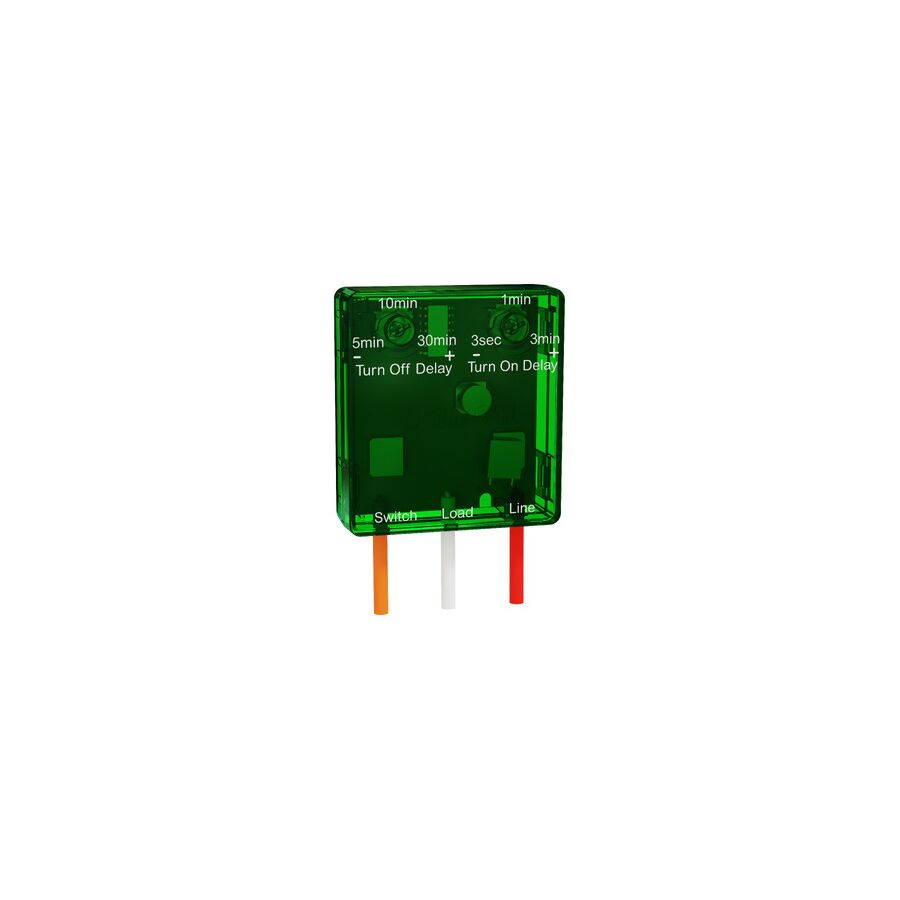

The run on timer addresses this by enforcing a dwell time. This is the period during which the exhaust fan continues operating after the user turns off the light or exits the space. Typical dwell times range from 5 to 30 minutes and are selected based on room volume, fan capacity, and expected moisture load. This extended operation ensures the fan completes sufficient air changes per hour to return humidity to ambient levels, protecting both occupant health and building materials.

Three-Wire Logic and Electrical Configuration

Although the user experience is simple, the electrical logic behind a run on timer requires precise understanding. Unlike a standard switched appliance, the timer must remain powered after the switch signal is removed. This is achieved through a three-wire configuration.

The required conductors are Neutral, Switched Active, and Permanent Active. The Switched Active acts as the trigger, usually derived from the bathroom light circuit. When the switch is turned on, the fan starts immediately. When the switch is turned off, the timer detects the loss of the trigger but continues to energise the fan using the Permanent Active supply for the programmed duration.

This design has important implications for retrofit installations. In many older Australian homes, a permanent active may not be present at the fan location. In such cases, additional cabling is required, and work must be carried out by a licensed electrician in accordance with AS/NZS 3000. Failure to provide a permanent active results in a timer that cannot function as designed.

Thermal Stress and Component Reliability

Run on timers are commonly installed in roof cavities, behind switch plates, or above ceilings. These environments are among the harshest in residential construction. Summer roof space temperatures routinely exceed 60 degrees Celsius, while winter conditions create repeated thermal cycling.

Electronic components that are not designed for these conditions suffer from premature failure. Capacitors drift, timing accuracy degrades, and relays weld or stick. This is where product selection becomes critical. Components engineered for high-temperature operation and long duty cycles significantly outperform generic devices.

The Schnap Electric Products ecosystem addresses this requirement by specifying timer modules built with heat-tolerant polymers, stable timing circuitry, and mechanically robust relay contacts. Many designs also incorporate modular plug bases, allowing the timer module to be replaced without disturbing fixed wiring. This reduces maintenance time and long-term lifecycle cost for strata managers and facilities teams.

Acoustic Control and Energy Efficiency

While moisture control is the primary function, run on timers also play a role in acoustic comfort and energy management. Continuous fan operation is undesirable, particularly in apartments and hotels where noise transmission between units is a concern. At the same time, excessive fan runtime extracts conditioned air, increasing heating and cooling loads.

Adjustable run on timers allow precise tuning of the overrun period. Smaller ensuites may require only a short dwell time, while larger bathrooms or commercial change rooms benefit from extended operation. This balance ensures moisture is removed without unnecessary energy loss or noise pollution, supporting both sustainability objectives and occupant comfort.

Load Characteristics and Switching Strategy

Most bathroom exhaust fans are inductive loads. When they start, they draw a higher inrush current than their steady-state rating. Run on timers must be rated appropriately to handle this load profile. Underrated contacts suffer from arcing and premature failure.

In higher-power or commercial applications, best practice is to use the run on timer as a control device rather than a load-bearing switch. The timer energises a relay or contactor that handles the fan motor current. This architecture significantly increases system longevity and aligns with professional HVAC control design principles.

Compliance, Procurement, and Installation Standards

Run on timers installed in Australia must comply with RCM requirements and be suitable for the electrical environment in which they operate. Devices must be rated for inductive loads and meet electromagnetic compatibility standards to prevent interference with other building services.

Professional contractors source these components through electrical wholesaler who act as compliance and quality gatekeepers. These suppliers ensure compatibility with Australian wiring practices and provide access to mounting accessories, isolation switches, surface sockets, and enclosures that support compliant installation. Proper procurement reduces risk and ensures consistent performance across multiple projects.

Conclusion

The run on timer is a small but critical component in healthy building design. By automating ventilation overrun, it removes reliance on human behaviour and ensures moisture is fully evacuated from wet areas. When correctly specified, wired, and installed, it protects building fabric, improves indoor air quality, and reduces long-term maintenance costs.

By understanding dwell time physics, three-wire control logic, and environmental durability requirements, and by selecting robust hardware from manufacturers such as Schnap Electric Products, Australian industry professionals can deliver ventilation systems that perform reliably in both residential and commercial settings. In effective moisture management, time is not optional; it is the control variable that defines success.

Recent posts

Electrical Wholesaler

SCHNAP is Australia's premier electrical wholesaler and electrical supplies, marketing thousands of quality products from leading brands. Trusted for nearly two decades by licensed electricians, contractors, and engineers, our range covers everything from basic electrical components to complex industrial electrical equipment

Top Electrical Wholesaler

Our key categories include: LED lighting, designer switches, commercial switchboards, circuit protection, security systems & CCTV, and smart home automation

Online Electrical Wholesaler

All products are certified to Australian standards (AS/NZS), backed by our 30-day, no-questions-asked return policy. Our expert technical team helps you quickly source the right solution for any residential, commercial, or industrial project, with daily dispatch from our Sydney electrical warehouse delivering Australia-wide

Best Electrical Supplies

SCHNAP offers the most comprehensive electrical product range, with full technical specifications, application details, installation requirements, compliance standards, and warranties — giving professionals total confidence in every purchase

Customer Support

Information

Contact Us

-

-

-

-

Mon - Fri: 6:30AM to 5:00PM

-

Sat: 8:00AM to 2:00PM

-

Sun: 9:00AM to 2:00PM

-

Jannali Branch:

-

-

Closed for Renovations

© 2004 - 2026 SCHNAP Electric Products