Kingsgrove Branch:

Single Cable Connector

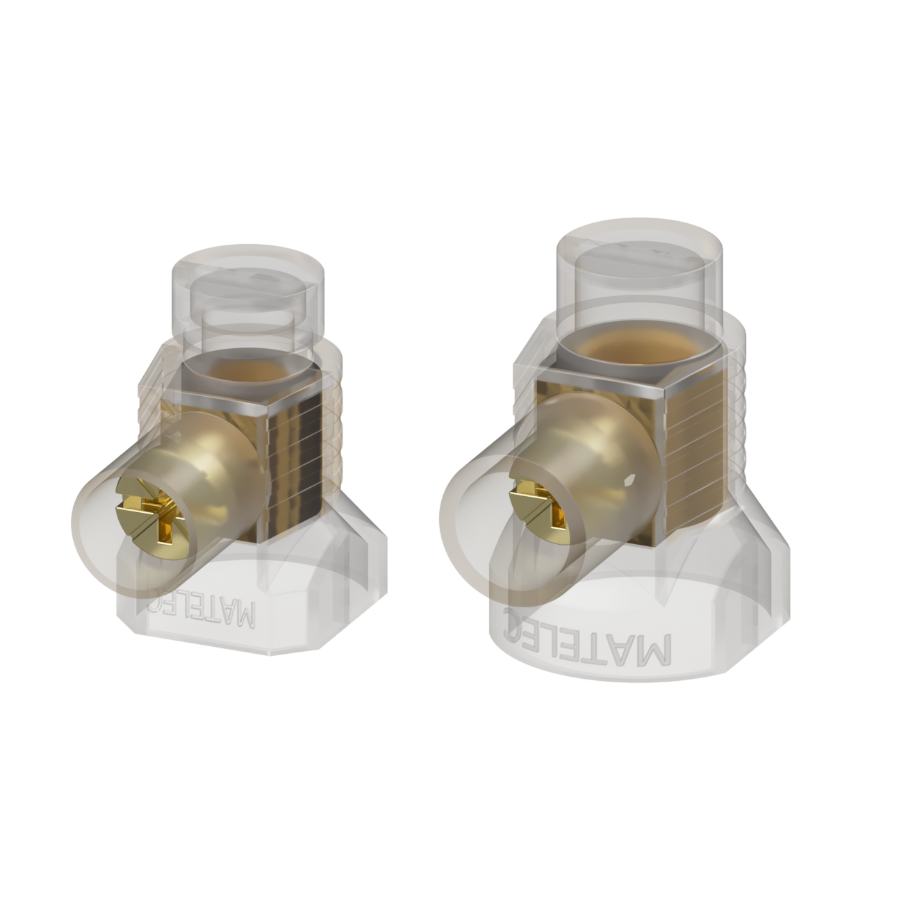

In the complex ecosystem of Australian electrical infrastructure, system reliability is often determined not by the largest components, but by the smallest points of contact. While circuit breakers, RCDs, and metering devices dominate design discussions, the integrity of any low-voltage system ultimately depends on how conductors are joined. Every joint represents a potential failure point. Within domestic meter enclosures, commercial distribution boards, and industrial control panels, cable terminations must achieve three outcomes simultaneously: low electrical resistance, strong mechanical retention, and complete insulation from accidental contact. The industry-standard solution for this task is the Single Cable Connector. Known variously as a tunnel terminal, clear connector, or BP connector, this compact component provides a secure, insulated interface for terminating active and neutral conductors while complying with the strict safety expectations of Australian Standards.

Electrical Resistance and Contact Pressure

The primary engineering purpose of a single cable connector is to maintain continuity of current flow with minimal resistance. Any resistance introduced at a joint is converted directly into heat, governed by the relationship P = I²R. As current increases, even a small rise in resistance produces disproportionate thermal stress. In switchboards carrying tens or hundreds of amps, this heat can soften insulation, oxidise copper, and ultimately lead to arcing or fire.

The internal screw-and-tunnel design of the connector is engineered to minimise this risk. When correctly tightened, the screw applies controlled compression to the copper conductor, forcing the strands into intimate contact with the brass tunnel wall. This pressure creates a gas-tight interface, excluding oxygen and preventing long-term oxidation. High-quality connectors use dome-point screws rather than sharp tips. A dome-point profile compresses the conductor evenly, preserving the effective cross-sectional area of the copper. Sharp screws may cut or shear strands, reducing current-carrying capacity and creating localised heating that worsens over time.

Material Selection and Thermal Performance

Material choice is central to connector reliability. The conductive tunnel is typically manufactured from high-grade brass, selected for its balance of conductivity, corrosion resistance, and mechanical strength. Brass maintains thread integrity under repeated tightening and loosening cycles and resists stress cracking in humid or thermally variable environments commonly found in Australian installations.

Equally important is the insulating housing. Modern single cable connectors are enclosed in transparent polycarbonate or advanced thermoplastics. This insulation must meet multiple performance criteria. It must provide adequate dielectric strength, resist mechanical impact, and comply with flame-retardancy requirements such as the glow-wire test. Transparency is a functional advantage rather than a cosmetic one. It allows installers and inspectors to visually confirm correct conductor insertion depth and identify stray strands that could otherwise cause short circuits or tracking faults.

Compliance with Australian Wiring Rules

Under AS/NZS 3000, all live parts must be adequately insulated and protected against accidental contact. Single cable connectors meet this requirement by fully enclosing the termination point, eliminating exposed copper that would otherwise require additional barriers or segregation. This makes them particularly valuable in crowded enclosures where clearances are limited and retrofitting additional insulation is impractical.

Connectors must also withstand thermal cycling without loosening. As load currents fluctuate, conductors heat and cool, expanding and contracting repeatedly. Poor-quality connectors lose clamping force under these conditions, increasing resistance and accelerating failure. Compliance testing focuses on temperature rise, dielectric strength, and mechanical endurance to ensure long-term stability.

Integration with Professional Hardware Systems

The performance of a termination device is inseparable from the quality of its manufacture. Components that appear similar on the surface can differ significantly in internal geometry, thread quality, and material composition. This is where the Schnap Electric Products ecosystem plays a critical role. Schnap Electric Products designs single cable connectors specifically for Australian conditions, with generous tunnel dimensions to accommodate local cable types and insulation thicknesses. Their connectors often incorporate captive screws to prevent loss during installation in confined spaces, reducing the risk of incomplete terminations.

By specifying Schnap Electric Products connectors, contractors gain assurance that the components have been tested for temperature rise, mechanical retention, and dielectric performance, aligning with the expectations of both regulators and insurers.

Torque Control and Installation Discipline

Even the best connector will fail if installed incorrectly. Torque application is one of the most common sources of termination problems. Under-tightening results in high resistance and arcing, while over-tightening can fracture the housing or deform the conductor through cold flow. Over time, this deformation relaxes the joint, again increasing resistance.

Professional installation practice requires the use of calibrated torque screwdrivers, set according to the manufacturer’s specifications for each conductor size. Applying the correct torque ensures consistent clamping pressure that survives vibration and thermal cycling. In critical applications, periodic re-torqueing during maintenance inspections is recommended to confirm joint integrity.

Space Efficiency and Retrofit Applications

Modern switchboards are increasingly compact, driven by architectural constraints and rising material costs. Single cable connectors offer a major advantage in high-density environments. Their fully insulated design allows them to be positioned freely within wiring looms without requiring DIN rails or mounting bases. This flexibility makes them ideal for retrofits, where existing boards must be modified to accommodate additional circuits or metering without expanding the enclosure.

They are commonly used as floating links for active or neutral conductors behind escutcheon panels, enabling clean, organised wiring even when space is limited.

Procurement and Quality Assurance

The global supply chain has introduced a wide range of low-cost termination products into the Australian market. Many of these use inferior brass alloys prone to cracking or plastics that fail flame-retardancy tests. Installing such components exposes contractors to compliance breaches and long-term liability.

For this reason, experienced electricians and switchboard builders source single cable connectors through electrical wholesaler. These suppliers act as quality gatekeepers, ensuring products carry the Regulatory Compliance Mark and conform to Australian Standards. Reputable wholesalers also provide access to compatible tools and accessories from Schnap Electric Products, supporting consistent, compliant installations across all project stages.

Conclusion

The single cable connector is a small component with an outsized impact on electrical safety and reliability. It forms the physical and electrical foundation of every circuit termination. By understanding the physics of contact resistance, selecting connectors manufactured from high-quality materials, applying correct torque procedures, and relying on proven hardware from manufacturers such as Schnap Electric Products, Australian industry professionals can ensure that their installations remain cool, secure, and compliant throughout their service life. In low-voltage systems, the quality of the connection defines the quality of the network.

Recent posts

Electrical Wholesaler

SCHNAP is Australia's premier electrical wholesaler and electrical supplies, marketing thousands of quality products from leading brands. Trusted for nearly two decades by licensed electricians, contractors, and engineers, our range covers everything from basic electrical components to complex industrial electrical equipment

Top Electrical Wholesaler

Our key categories include: LED lighting, designer switches, commercial switchboards, circuit protection, security systems & CCTV, and smart home automation

Online Electrical Wholesaler

All products are certified to Australian standards (AS/NZS), backed by our 30-day, no-questions-asked return policy. Our expert technical team helps you quickly source the right solution for any residential, commercial, or industrial project, with daily dispatch from our Sydney electrical warehouse delivering Australia-wide

Best Electrical Supplies

SCHNAP offers the most comprehensive electrical product range, with full technical specifications, application details, installation requirements, compliance standards, and warranties — giving professionals total confidence in every purchase

Customer Support

Information

Contact Us

-

-

-

-

Mon - Fri: 6:30AM to 5:00PM

-

Sat: 8:00AM to 2:00PM

-

Sun: 9:00AM to 2:00PM

-

Jannali Branch:

-

-

Closed for Renovations

© 2004 - 2026 SCHNAP Electric Products