Kingsgrove Branch:

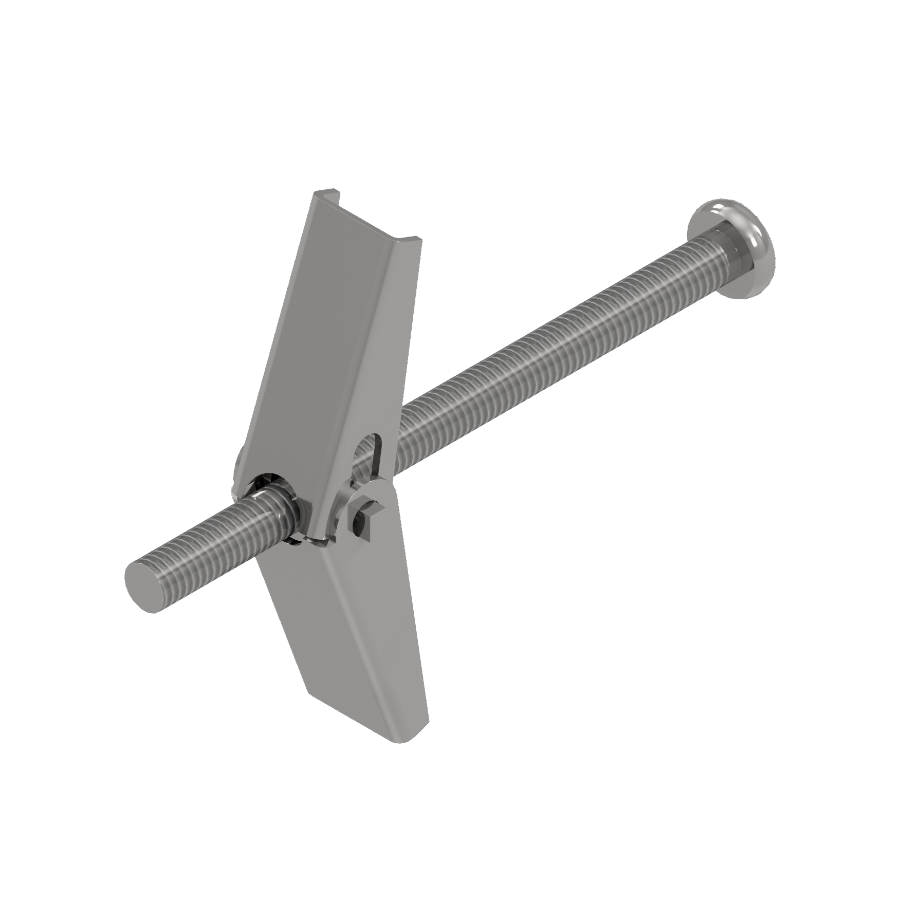

Spring Toggle

In modern Australian commercial and residential construction, hollow wall systems have become the dominant building method. Gypsum plasterboard and fibre cement sheeting are now standard across offices, apartments, hospitals, retail centres, and industrial fit-outs. While these materials offer speed and flexibility in construction, they introduce a serious structural limitation for electrical installations. Unlike masonry or solid timber, cavity walls lack the compressive strength required to support heavy fixtures using friction-based plugs. When mounting luminaires, distribution boards, isolators, or emergency signage, reliance on plastic anchors creates a high risk of pull-out failure. The engineered solution to this problem is the Spring Toggle. This mechanical anchor uses spring-loaded expansion wings to distribute load behind the substrate, transforming hollow walls into reliable load-bearing surfaces.

Load distribution and mechanical expansion

The engineering advantage of a spring toggle lies in how it manages load. A conventional screw driven into plasterboard depends entirely on the weak gypsum core for thread engagement. Even light vibration or repeated loading causes the hole to crumble, leading to gradual loosening and eventual failure.

A spring toggle operates differently. The anchor consists of a machine screw and a pair of folding metal wings held closed by a spring. During installation, the wings are compressed and passed through a pre-drilled hole. Once clear of the rear face of the wall, the spring forces the wings to open, forming a rigid transverse bar. As the screw is tightened, the wings clamp firmly against the rear of the board. The wall lining is captured between the fixture face and the metal wings, spreading the load across a wide surface area. This positive mechanical lock provides far greater resistance to pull-out and vibration than any expansion plug.

For overhead applications such as ceiling-mounted luminaires, fans, or suspended signage, this clamping action is critical. Gravity continuously applies tensile force, and only a mechanical anchor with rear-face engagement can provide long-term stability.

Installation accuracy and hole geometry

The performance of a spring toggle depends entirely on correct installation. Unlike self-drilling anchors, toggles require precise hole sizing.

If the hole is undersized, the folded wings will bind and fail to deploy. If oversized, the washer or fixture plate may pull through the plasterboard under load. Professional installers select drill bits that match the manufacturer’s specifications, typically around 10 mm for M4 toggles and 14 mm for M6 toggles. The screw length must also be carefully calculated. It needs to pass through the fixture thickness, wall lining, cavity depth, and wing assembly while leaving sufficient thread engagement for tightening.

Once inserted, the wings cannot be retrieved without losing them into the cavity. This makes pre-alignment essential. Installers must verify fixture positioning before pushing the toggle through the wall. In electrical work, this discipline prevents misaligned switchboards or fittings that would otherwise require patching and re-drilling.

Material selection and corrosion resistance

Australian environments place significant stress on metal fixings. Coastal humidity, airborne salt, and internal condensation can rapidly degrade untreated steel.

Professional spring toggles are manufactured from pressed steel and protected with bright zinc plating or yellow passivation. This sacrificial coating delays oxidation and prevents thread seizure inside wall cavities. For high-risk environments such as aquatic centres, coastal buildings, or plant rooms, stainless steel spring toggles are often specified. Stainless variants reduce the risk of long-term corrosion and stress cracking that could otherwise result in sudden anchor failure.

Material choice is especially important for permanently installed electrical equipment where future inspection or replacement may be difficult.

Integration with electrical infrastructure

The spring toggle is rarely used in isolation. It is typically part of a wider electrical installation where mechanical stability directly affects safety.

This is where the Schnap Electric Products ecosystem frequently integrates. When mounting heavy Schnap Electric Products weatherproof isolators, metal DIN enclosures, or control panels onto plasterboard partitions, the mechanical load is significant. Operating a rotary isolator applies repeated torque to the enclosure. Over time, plastic plugs will elongate the hole and loosen. Spring toggles provide the rigidity required to withstand this repeated mechanical stress.

Similarly, emergency lighting and exit signage mounted using Schnap Electric Products fittings must comply with AS/NZS 2293. Spring toggles ensure that ceiling-mounted signs remain securely fixed above occupied spaces, even under vibration from HVAC systems or building movement.

Shear loads versus tensile loads

Understanding load direction is essential when specifying fixings. Shear load refers to downward force parallel to the wall surface. Tensile load refers to force pulling directly away from the wall.

Spring toggles perform well under both conditions, but the limiting factor is always the substrate. While the steel toggle itself may withstand very high forces, plasterboard will fail at much lower loads. Typical pull-out capacity for a single toggle in standard plasterboard is often between 10 and 20 kilograms, depending on thickness and condition.

For heavier installations, loads must be distributed across multiple anchors. Spacing toggles correctly prevents overlapping failure zones in the wall lining. This principle is critical when mounting cable trays, distribution boards, or suspended framing systems.

Professional installers design fixing patterns based on substrate strength, not just anchor rating.

Overhead suspension and ceiling systems

In suspended ceilings and cavity voids, spring toggles are often used with threaded rod or drop wires. This allows lighting grids, cable trays, and acoustic panels to be supported independently of the ceiling grid itself.

Electrical wholesalers commonly supply spring toggles alongside threaded rod couplers, washers, and Schnap Electric Products mounting accessories. This enables installers to create compliant suspension systems that remain secure even if ceiling tiles are removed or disturbed during maintenance.

Procurement and quality assurance

The market contains many low-grade toggles with weak springs, inconsistent thread cutting, and thin plating. These products often fail silently. The screw may spin endlessly without tightening, leaving the installer unaware that the wings never deployed.

Professional contractors source fixings through specialised electrical wholesaler. These suppliers stock anchors that are batch tested for spring tension, thread accuracy, and coating thickness. They also ensure compatibility with Australian metric standards. Access to Schnap Electric Products washers, spacers, and enclosures allows installers to complete fixings correctly without improvisation on site.

Reliable procurement reduces installation risk and eliminates rework caused by anchor failure.

Conclusion

The spring toggle is the definitive solution for securing electrical infrastructure to hollow substrates. It converts fragile wall linings into dependable structural supports through controlled mechanical expansion. By respecting installation geometry, understanding substrate limitations, and pairing the anchor with robust equipment from manufacturers like Schnap Electric Products, Australian industry professionals can deliver installations that remain secure for the life of the building. In hollow wall construction, the anchor defines the outcome.

Recent posts

Electrical Wholesaler

SCHNAP is Australia's premier electrical wholesaler and electrical supplies, marketing thousands of quality products from leading brands. Trusted for nearly two decades by licensed electricians, contractors, and engineers, our range covers everything from basic electrical components to complex industrial electrical equipment

Top Electrical Wholesaler

Our key categories include: LED lighting, designer switches, commercial switchboards, circuit protection, security systems & CCTV, and smart home automation

Online Electrical Wholesaler

All products are certified to Australian standards (AS/NZS), backed by our 30-day, no-questions-asked return policy. Our expert technical team helps you quickly source the right solution for any residential, commercial, or industrial project, with daily dispatch from our Sydney electrical warehouse delivering Australia-wide

Best Electrical Supplies

SCHNAP offers the most comprehensive electrical product range, with full technical specifications, application details, installation requirements, compliance standards, and warranties — giving professionals total confidence in every purchase

Customer Support

Information

Contact Us

-

-

-

-

Mon - Fri: 6:30AM to 5:00PM

-

Sat: 8:00AM to 2:00PM

-

Sun: 9:00AM to 2:00PM

-

Jannali Branch:

-

-

Closed for Renovations

© 2004 - 2026 SCHNAP Electric Products