Kingsgrove Branch:

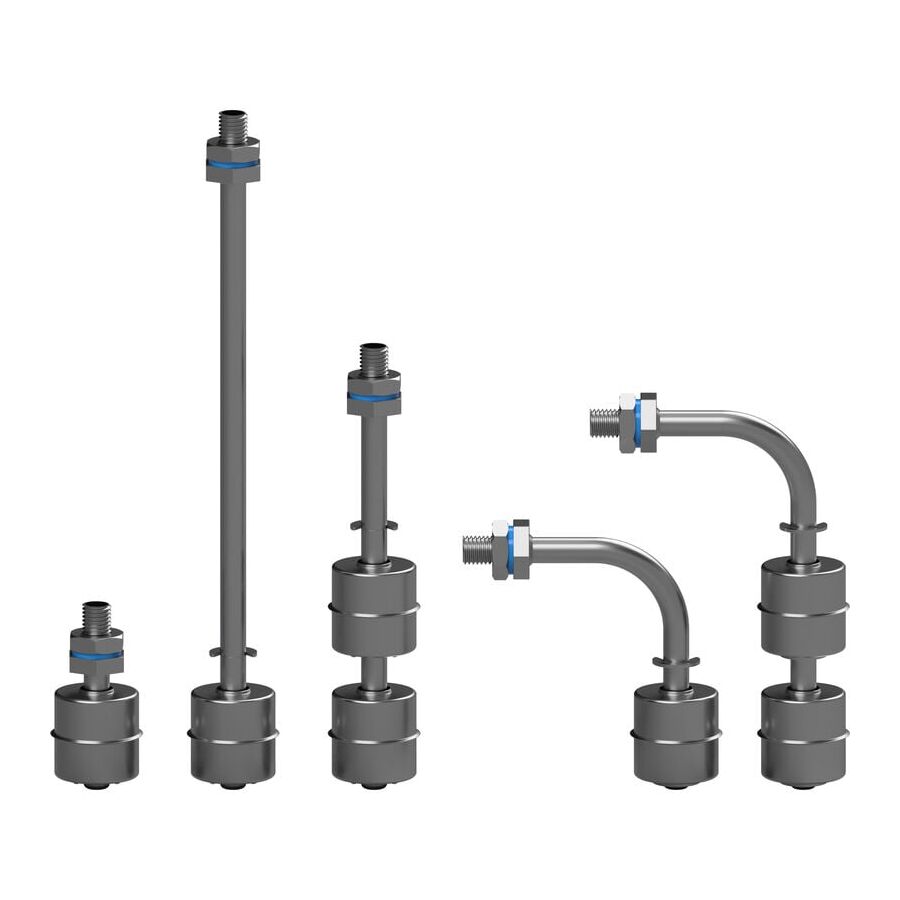

Stainless Steel Float Switch

Across Australian industrial processing sectors, liquid level monitoring is a mission-critical function. In mining, food and beverage, pharmaceuticals, water treatment, and energy production, the consequences of inaccurate level detection can be severe, ranging from pump damage and production downtime to environmental contamination and safety breaches. While thermoplastic float switches are widely used in benign water applications, they are fundamentally unsuitable for environments involving corrosive chemicals, elevated temperatures, abrasive slurries, or strict hygiene controls.

In these demanding conditions, the engineering standard is the Stainless Steel Float Switch. Constructed from austenitic stainless steel, most commonly grades 304 or 316, this device delivers mechanical durability, chemical resistance, and thermal stability that polymer-based sensors cannot achieve. It is not simply a more expensive alternative to plastic; it is a different class of instrumentation designed for environments where material science directly determines system reliability.

Metallurgy and Corrosion Resistance: Choosing 304 or 316

The performance of a stainless steel float switch is defined first by its alloy composition. Grade 304 stainless steel offers strong mechanical properties and good resistance to oxidation, making it suitable for water, oils, and mild industrial fluids. In controlled indoor environments, 304 performs reliably for years without degradation.

However, many Australian installations are far from controlled. Coastal facilities, mining operations, and chemical plants often expose instrumentation to chlorides, saline water, or aggressive cleaning chemicals. In these conditions, 304 stainless steel is vulnerable to pitting corrosion, which compromises wall thickness and ultimately leads to failure.

For these applications, 316 stainless steel is the professional specification. The addition of molybdenum significantly increases resistance to pitting and crevice corrosion, particularly in chloride-rich environments. This makes 316 the standard choice for chemical dosing tanks, pharmaceutical reactors, medical sterilisation systems, and coastal infrastructure. In food and beverage plants, 316 stainless steel is also essential for withstanding repeated Clean-In-Place cycles using caustic soda, nitric acid, or peracetic acid.

Thermal Stability in High-Temperature Processes

Temperature exposure is a decisive factor in sensor selection. Plastic float switches begin to lose structural integrity at relatively modest temperatures. At around 80 degrees Celsius, many polymers soften, deform, or absorb fluid, altering buoyancy and switching accuracy.

Stainless steel float switches maintain their mechanical properties well beyond these limits. Standard industrial models are commonly rated to 125 degrees Celsius, with specialised variants exceeding this range. This makes them suitable for steam condensate tanks, hot wash systems, and boiler feed applications where temperature fluctuations are constant.

Equally important is the cable and sealing system. High-temperature stainless steel floats are typically paired with silicone or PTFE insulated cables rather than PVC. These materials resist embrittlement and cracking, ensuring that the electrical integrity of the sensor is preserved even under continuous thermal cycling.

Hygiene and Surface Finish Requirements

In regulated industries such as food processing, dairy production, and potable water treatment, hygienic design is non-negotiable. Any component in contact with product must be cleanable, non-reactive, and resistant to bacterial growth.

Stainless steel excels in this role due to its non-porous surface. High-quality stainless steel float switches are often electropolished, reducing microscopic surface roughness and eliminating crevices where biofilm can form. Unlike plastics, which can scratch and develop micro-harbourages, stainless steel can be repeatedly sterilised without degradation.

This hygienic resilience is why stainless steel float switches are standard in milk vats, brewery fermentation vessels, syrup tanks, and pharmaceutical storage systems. Compliance with HACCP principles and internal audit requirements is far easier when instrumentation materials support thorough cleaning and validation.

Switching Mechanism and Specific Gravity Considerations

Most stainless steel float switches operate using a magnetic reed switch housed within the stem. As the float rises or falls with the liquid level, an internal magnet actuates the reed switch, opening or closing the circuit. This design is simple, reliable, and hermetically sealed from the process fluid.

However, material density introduces an important engineering variable: specific gravity. Stainless steel is denser than plastic, so the float must be carefully engineered to ensure sufficient buoyancy. The float’s internal volume and wall thickness determine the minimum fluid density required for operation.

A float designed for water, with a specific gravity near 1.0, may not function correctly in lighter fluids such as diesel or certain oils. Conversely, in dense or abrasive slurries, buoyancy is increased, but mechanical strength becomes critical to resist wear. Engineers must always match the float’s buoyancy specification to the process fluid to avoid false readings or non-operation.

Control Integration and Electrical Protection

While the float switch provides level indication, it is rarely suitable for directly switching industrial loads. The internal reed switch is typically rated for low current control circuits, not for pump motors or heaters.

This is where proper control integration is essential. The float switch should be used as a signal device, controlling an interface relay or contactor that handles the load current. The Schnap Electric Products ecosystem supports this architecture through industrial relays, modular contactors, and stainless steel mounting hardware.

In a typical installation, the float switch operates at 24V DC, energising a control relay. The relay then switches the high-voltage supply to a pump or valve. This separation protects the float switch from electrical stress, improves system safety, and significantly extends sensor life. Schnap Electric Products mounting flanges and brackets also allow secure installation on tanks without compromising pressure ratings or ingress protection.

Procurement and Compliance Assurance

Not all “stainless” sensors are equal. The market contains many low-quality products made from plated brass or low-grade steel that corrode rapidly once immersed. In regulated industries, using uncertified materials introduces serious compliance and liability risks.

Professional engineers source stainless steel float switches through electrical wholesaler. These suppliers verify material certification, cable temperature ratings, and ingress protection levels, often IP68 for continuous immersion. They also provide compatible glands, conduit fittings, and accessories to ensure the installation maintains its environmental rating from sensor to control panel.

Conclusion

The stainless steel float switch is the definitive solution for liquid level monitoring in environments where plastics fail. Its strength lies in material science: corrosion resistance, thermal stability, and hygienic performance. By selecting the correct stainless steel grade, accounting for specific gravity, and integrating the sensor with robust control hardware from manufacturers like Schnap Electric Products, Australian industry professionals can build level control systems that are safe, compliant, and long-lasting.

In industrial process control, reliability is not optional. With stainless steel instrumentation, reliability is engineered.

Recent posts

Electrical Wholesaler

SCHNAP is Australia's premier electrical wholesaler and electrical supplies, marketing thousands of quality products from leading brands. Trusted for nearly two decades by licensed electricians, contractors, and engineers, our range covers everything from basic electrical components to complex industrial electrical equipment

Top Electrical Wholesaler

Our key categories include: LED lighting, designer switches, commercial switchboards, circuit protection, security systems & CCTV, and smart home automation

Online Electrical Wholesaler

All products are certified to Australian standards (AS/NZS), backed by our 30-day, no-questions-asked return policy. Our expert technical team helps you quickly source the right solution for any residential, commercial, or industrial project, with daily dispatch from our Sydney electrical warehouse delivering Australia-wide

Best Electrical Supplies

SCHNAP offers the most comprehensive electrical product range, with full technical specifications, application details, installation requirements, compliance standards, and warranties — giving professionals total confidence in every purchase

Customer Support

Information

Contact Us

-

-

-

-

Mon - Fri: 6:30AM to 5:00PM

-

Sat: 8:00AM to 2:00PM

-

Sun: 9:00AM to 2:00PM

-

Jannali Branch:

-

-

Closed for Renovations

© 2004 - 2026 SCHNAP Electric Products